Product: NX CAM

Industry: Electronics and Semiconductors

Siemens Digital Industries Software solutions enable ASM Pacific Technology Ltd. to improve production efficiency and quality by 70 percent

Looking for solutions to keep pace with advancements in electronics technology

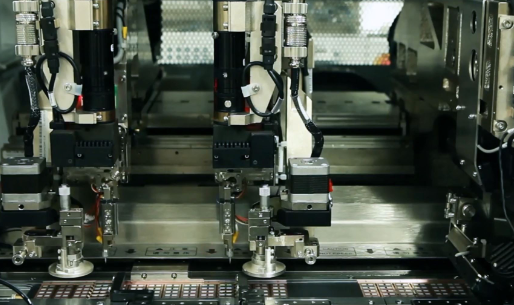

ASM Pacific Technology Ltd. (ASM) is the world’s largest supplier of semiconductor and light-emitting diode (LED) manufacturing and assembly equipment. ASM specializes in providing LED manufacturing and assembly equipment for chip manufacturers, integrated circuit (IC) manufacturing and assembly factories, and consumer electronics manufacturers. With the acceleration of electronics technology advancements, upstream manufacturing equipment providers are tasked with producing more sophisticated equipment in shorter cycle times. As the industry leader, ASM places high value on product development and production, investing 10 percent of its yearly sales revenues into product development. But the system and geographical separations between its research and development centers and manufacturing factories (each with locations throughout Asia and Europe) created significant gaps between ASM’s design, development and production activities.

Overcoming challenges using NX CAM

Directly applying three-dimensional (3D) product models to production/manufacturing activities proved difficult because the models lacked complete product information. Also, it was impossible for the manufacturing processes adopted by the factories to capture design intent, making it difficult for product data to flow between computer-aided design (CAD) and computer-aided manufacturing (CAM).

Because of the significant time required to transfer design changes from the product development center to manufacturing, ASM realized it needed to integrate CAD and CAM. The full integration of design and manufacturing could eliminate problems associated with design and production automation and efficiency, while supporting an upgrade of the company’s business and processes.

“Product development and production are the core parts of ASM,” says Chen Lizhi, director of ASM MIS information and tele-communications technology. “ASM invests 10 percent of sales in product development activities. We have several product development centers and manufacturing factories around the globe. In order to thoroughly eliminate the seamless connection problems in linking design and production, we decided to deploy a computerized system at the production/manufacturing stage, using NX as the standard parts machining soft-ware platform to deploy the computerized system uniformly.

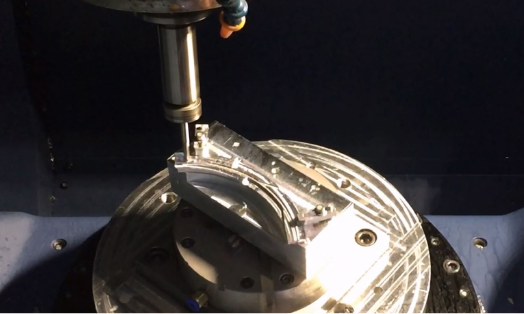

“We began using NX CAM software from Siemens Digital Industries Software in manufacturing factories in 2000. We have deployed more than 100 suites in factories all over the world, including those in Shenzhen, Singapore and Malaysia.” Successful digitalization has pushed productivity to a new level.

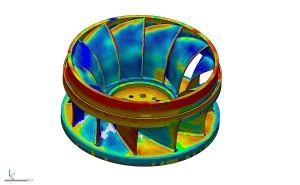

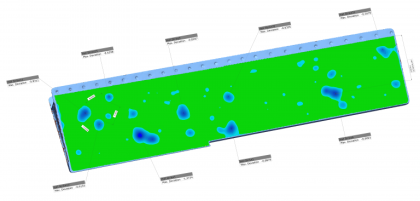

FBM keys more efficient processes

The most immediate benefit of applying NX™ software is that its feature-based machining (FBM) capability eliminates the data barriers between design and manufacturing. With FBM technology, NX CAM can automatically read and identify product and manufacturing information (PMI), tolerances, surface machining precision, and other information attached to 3D product models, and automatically select machining methods, processes and tools while also directly driving numerical control (NC) programming and machining.

In addition, feature-based machining enables automatic transfer of related data between CAD and CAM, and automatically identifies features and creates standardized NC programs for machining processes. ASM can now minimize human error while maximizing efficiency and accuracy.

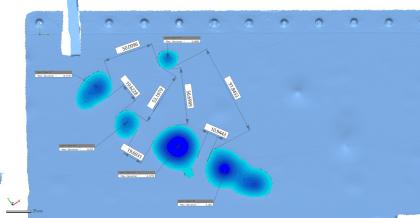

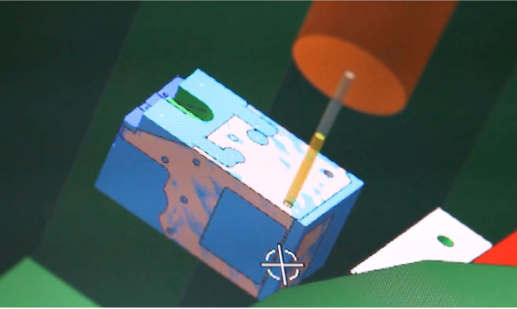

Meanwhile, with the NX CAM integrated simulation and verification (ISV) capability, significantly reducing programming errors and improving machining quality. ASM’s engineers no longer need to conduct tests on physical machine tools. Instead, they can check the NC programming of tool paths for accuracy and reliability in a virtual environment, and verify the tool path and material removal process in a 3D environment. Machine tool simulation driven by G-code drives the true movement of the machine tool’s 3D model (including fixtures and tools), thus ensuring the first-time success of machining in the real world.

With more advanced machining and manufacturing technologies, ASM is marching toward the goal of building smart factories.

“NX CAM’s feature-based machining enables us to truly experience the seamless connection between CAD and CAM, enabling manufacturing to respond more quickly to design changes, thus significantly reducing the time of responding to user requirements and reducing time-to-market,” says Hu Dewen, senior CAD/CAM manufacturing manager at ASM. “Our statistical results show that feature-based machining and PMI have improved the production efficiency and quality of ASM by 70 percent, thus saving a lot of valuable time.”