Siemens

CFD for clean air. 3 ways to fight contamination in public buildings, transportation and production facilities

Industria: CFD

CFD for clean air: How simulation is transforming spaces and processes.

Until 2020, Computational Fluid Dynamics (CFD) for ensuring clean air was not a topic that captured the attention of the general public. However, with the COVID-19 pandemic, the need for clean and healthy air became a matter of global concern. This led to CFD reaching the mainstream media. Although public attention has been reduced following the pandemic, the need for purified air in public facilities, offices and transportation remains crucial. Moreover, it is not only humans who require high standards of air quality; many industries need controlled environments to avoid contamination that can affect the production of goods.

CFD simulation is an essential tool in this ongoing challenge. Simulation software from Siemens’ Simcenter portfolio is used in a variety of applications to ensure that air is purified, improving both our breathing and manufacturing processes.

Three ways CFD helps ensure clean air

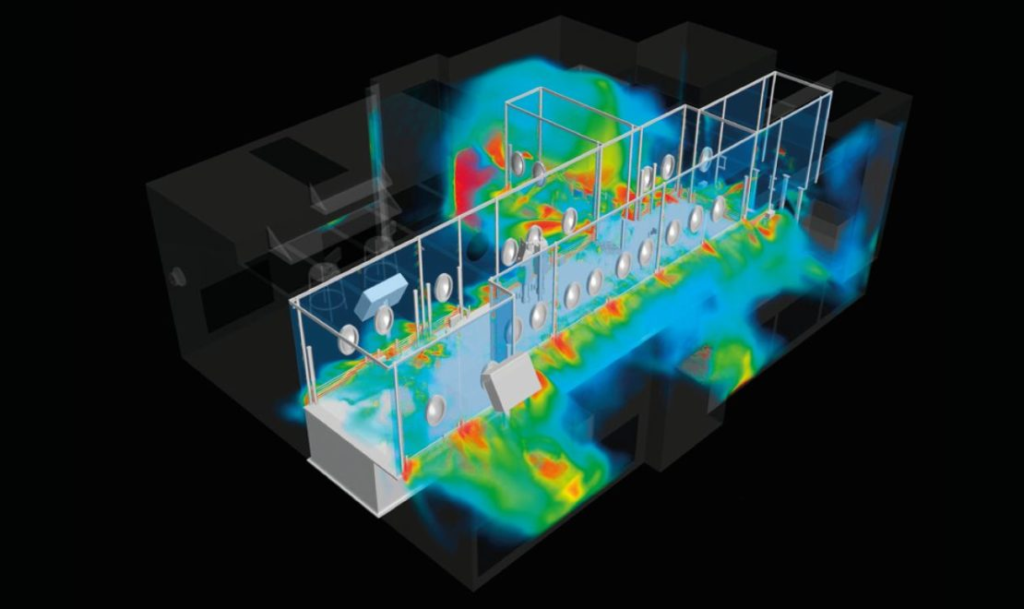

While CFD simulations do not replace public health guidelines, they can be useful in three key areas:

- Understanding pollutant transport and mitigation 2.

CFD allows modeling the movement of aerosols and particles in space and time. This is especially useful in controlled indoor spaces such as rooms, automobiles, trains, airplanes, clean rooms, and food factories. - Improve and redesign indoor spaces for safety.

With CFD, multiple configurations for ventilation systems can be analyzed, ensuring efficient removal of particulate contaminants in indoor spaces. It is also possible to optimize the location of air purifiers and air barriers. - Designing equipment to remove hazardous substances and purify air.

CFD enables the design of more efficient air purification devices used in public buildings, transportation and industrial environments.

CFD case studies for clean air

Public transportation

- Airbus: Used Simcenter STAR-CCM+ to model the transport of cough particles in aircraft cabins, evaluating the effectiveness of face masks.

- Norton Straw:** Analyzed ventilation strategies in trains, such as opening windows or installing plastic barriers, optimizing passenger safety.

Buildings

- HOLT Architects:** Redesigned office spaces to reduce airborne virus transmission. Simulations evaluated the effectiveness of HVAC systems, window openings and the use of disinfection devices.

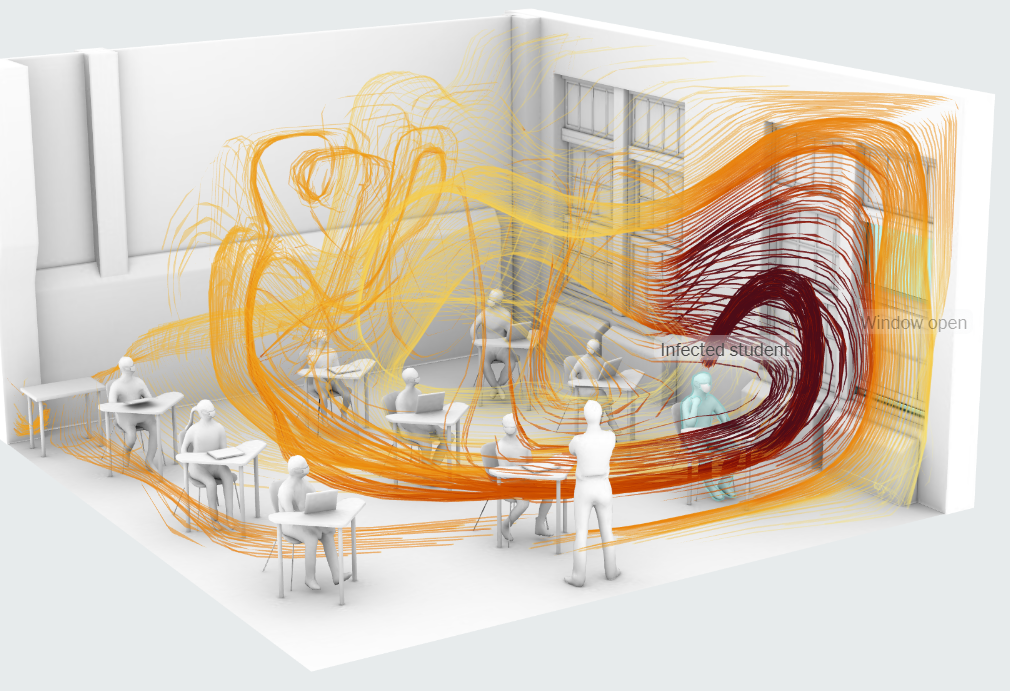

- JB&B:** Showed how opening windows in classrooms dilutes contaminants, helping to minimize the risk of contagion in schools.

Industrial production

- FS Dynamics:** Developed an advanced methodology to avoid contamination on lithography machines in the semiconductor industry.

- Creaform Engineering: Simulated vaccine filling lines in clean rooms, ensuring regulatory compliance and minimizing economic losses.

Beyond Human: Purification in Industrial Processes

In addition to protecting people, CFD simulation plays a key role in maintaining hygienic standards in the production of food, drugs and other sensitive goods. Companies such as Excelitas Noblelight and Clean Air Limited have used CFD to design innovative devices, from UVC air purifiers to fume hoods, improving both efficiency and sustainability.

In short, Computational Fluid Dynamics not only helps improve the quality of the air we breathe, but also transforms key processes in multiple industries. Ready to explore what CFD can do for you?

Siemens Leads Innovation at the 5th Italian Exhibition Mexico Roadshow

The 5th Italian Exhibition Mexico Roadshow has established itself as a key event for the industry, offering a cutting-edge platform to explore how technological solutions are transforming the industrial sector. Led by Jean Macías, the event featured Gerardo Pérez Lechuga, Head of Digital, Enterprise and Cloud Solution at Siemens Mexico, Central America, and the Caribbean, who presented Siemens’ vision for a more sustainable future.

Siemens: A Pioneer in Sustainable Digital Transformation

During his presentation, Gerardo Pérez Lechuga emphasized Siemens’ commitment to industrial sustainability, showcasing how its comprehensive technological solutions drive operational efficiency while reducing environmental impact. Technologies such as cloud computing, the Internet of Things (IoT), and automation not only enhance processes but also optimize resource use and minimize waste, paving the way for a cleaner, more responsible manufacturing landscape.

“Digitalization is not just a competitive advantage; it is a shared responsibility to build a more sustainable future,” Pérez Lechuga stated, reaffirming Siemens’ role as a leader in digital solutions.

Driving the Future of Industry with Siemens

Siemens’ approach, centered on the integration of technology and sustainability, demonstrates that aligning business growth with positive environmental impact is not only achievable but also essential. Companies adopting this model strengthen their competitiveness while playing an active role in the transition toward a greener economy.

A Key Event for Industrial Transformation

With Siemens at the forefront, the 5th Italian Exhibition Mexico Roadshow provided immediate solutions and a clear vision for the future of the industry. The event demonstrated that digitalization and sustainability are not fleeting trends but foundational pillars for building a more efficient and environmentally conscious industrial landscape.

Through events like this, Siemens reinforces its commitment to leading the way toward a more responsible industry, equipping businesses with the tools they need to face today’s challenges and prepare for the future.

Implementing end-to-end Simcenter solutions for test-based durability engineering

Industry: Automotive & transportation

Tuning vehicles to local custom needs

In 2017, Nissan enjoyed a record year with 5,820,000 cars sold globally. That year, Renault-Nissan Alliance became the world’s leading seller of passenger vehicles, surpassing Volkswagen.

Nissan’s brand awareness and recognition is at its zenith. In fact, YouGov BrandIndex, which measures the public perception of thousands of brands in Europe, reports that Nissan is the fifth-ranked automobile supplier (of 38) for United Kingdom (UK) consumers.

To continue increasing brand perception, as well as improving the quality ranking, Nissan sets high standards in regard to engineering quality and reliability, it is essential to understand and address the needs and requirements of its local customers. The role of the Nissan Technical Centre in Europe (NTCE) is to support Nissan’s reputation and ensure that performance attributes of new vehicle designs and concepts meet European consumer expectations. Nissan Technical Centre Spain (NTCE-S) is a center of excellence for the design and development of vehicles manufactured across Nissan’s European production plants, focusing on key activities such as powertrain development, light commercial vehicle engineering and testing.

Nissan is committed to offering its European customers the highest standards of quality and reliability. This is one of the reasons why NTCE-S invested in Simcenter™ software solutions from Siemens Digital Industries Software for test-based durability engineering to bring its engineering capabilities to the next level.

Durability is key

The main role of the function and durability department at NTCE-S is to validate the functional performance of an engine’s components over the vehicle’s lifecycle. To assess performance, the team conducts extensive tests on components fitted on NTCE’s engine dynamometer (dyno). It also evaluates the component’s performance in a full assembly configuration, where the complete vehicle is positioned on the chassis dyno. Finally, the team puts passenger cars and light commercial vehicles (for example, pick-up segment) through fatigue tests, either on the test bench or the test track.

A large number of the tests performed by the function and durability team are durability tests. Durability is an important performance attribute of passenger and light commercial vehicles. In the light commercial vehicles market segment, consumers are inclined to select a brand they trust will support their daily needs.

“Durability is extremely important,” says Arturo Barreu, powertrain durability test engineer, function and durability department, NTCE-S. “In Europe, this attribute is closely associated with the perception of quality. As the demand for quality increases, we need to confirm the durability of our vehicles. Consumers expect vehicles will not break down after only one year, but up to 20 years.”

Other attributes such as ride and in-vehicle comfort, engine power and fuel efficiency are also important in the vehicle’s design. The role of a durability engineer has become more complex as durability engineering teams need to take more parameters into account when conceiving and testing components, subsystems and full systems of next-generation vehicles.

Streamlining processes

One of the steps the team took to improve durability engineering was to invest in solutions from the Simcenter portfolio. With its portfolio, Siemens Digital Industries Software helps streamline the engineering process by offering an end-to-end solution for test-based durability engineering.

A complete durability test campaign encompasses measurements on the engine dyno, followed by measurements on the chassis dyno, after which the test team moves to the test track. As the engineers are required to move the test equipment from one location to the next and to instrument the test item anew, they appreciate the portability and flexibility of Simcenter™ SCADAS hardware.

“We use Simcenter SCADAS for all our data acquisition tasks,” says Barreu. “It is a portable system which is very compact. It is also versatile, adjusting to our needs. With it, we can acquire different types of data such as acceleration or strain, using the same equipment. Our Simcenter SCADAS data acquisition systems total more than 100 channels, which we can easily transport from the engine dyno to the chassis dyno and to the test track and back.”

Beyond data acquisition, the team streamlined its durability engineering process by relying on Simcenter Testlab™ software for load and fatigue analysis. The software effectively supports every step of a testing campaign, from data acquisition to load classification and fatigue life prediction. Moreover, it forms part of a platform dedicated to multiphysics test-based performance engineering and, as such, better helps balance the contribution of various performance attributes such as acoustic, comfort and durability, combined with low weight and fuel economy, to the overall perceived quality and reliability.

The function and durability department’s main responsibility is to test and validate the functional performance of enginerelated components. The engineers, meanwhile, acquire, analyze and compare test data on a large number of components and engine subsystems. They combine the outcome of durability analyses, such as time at level, rain flow counting, range pair counting, level crossing, and fatigue life prediction, with typical noise, vibration, and harshness (NVH) analysis results, which can include peak hold spectra, order sections, colormaps, and many more. All durability and NVH data are acquired using the same Simcenter SCADAS hardware, and the analysis is performed in a single software environment, making it a very efficient process for the engineering team.

“The key challenge that we are confronted with is the consolidation of our knowledge,” says Barreu. “We have to test more components now than ever before. These components are also of a different nature. We test more and more electronic components and less mechanical parts. The collaboration with Siemens is essential to adapt to these changes and to validate these new components.”

For the validation of the component on the test rig, the team uses Simcenter Testlab to synthesize an equivalent damage profile and to consequently emulate the damaging events encountered during test track measurements on the rig. This highly efficient process significantly accelerates testing by realistically simulating the damage experienced by the component during the operational life of the vehicle.

NTCE engineers have found that Simcenter Testlab offers great stability, independent of channel count, making it easy for them to configure online analyses. The solution also provides fast and error-free data postprocessing thanks to the Process Designer functionality and offers immediate, clear reporting.

“Simcenter Testlab is our preferred tool for durability validation,” says Barreu. “It is easy to configure and allows us to automate processing. It is also a very good software for quick reporting and data sharing with our colleagues.”

The outcome of the tests produce reliable data that can be endlessly manipulated to deliver deep engineering insight into the fatigue behavior of the components. This data supports the definition of further tests or feeds the simulation models with trustworthy validated information.

“Simcenter Testlab offers an integrated end-to-end solution for load data acquisition and processing,” says Guillermo Gonzalez, function and durability senior engineer, NTCE. “The solution accelerates the delivery of critical durability insights when preparing for test rig campaigns or reliable simulations. It is faster, easier to use and robust.”

We test more and more electronic components and less mechanical parts. The collaboration with Siemens is essential to adapt to these changes and to validate these new components.

Arturo Barreu, Powertrain Durability Test Engineer Function and Durability Department, NTCE-S

Siemens Mexico Certifies Over 30,000 Students in Industrial Digitalization and Strengthens Dual Education

León, Gto. — Siemens Mexico has certified over 30,000 students in industrial digitalization tools, reaffirming its commitment to preparing future talent for the workforce. This initiative aims to integrate young professionals into the job market by combining wisdom and experience, which the company identifies as essential for business success.

Alejandro Preinfalk, CEO of Siemens Mexico, Central America, and the Caribbean, emphasized the importance of curiosity and a growth mindset in Mexican students. “Curiosity is the key ingredient for students to thrive and become industry leaders,” he stated.

Preinfalk highlighted Mexico’s potential to excel globally, provided that students maintain their sense of wonder and eagerness to learn. “A growth-oriented attitude is fundamental. We must not think we know everything already. The technologies and tools are available, but we need the right mindset to take full advantage of them,” he added.

Dual Education: A Proven Model

Siemens also promotes the “Dual Education” methodology, a strategy combining theory and practice. Originating in Germany, this model allows technical high school students to learn in the classroom while gaining hands-on experience in companies under direct mentorship. “This combination delivers excellent results, as it enables young people to seamlessly transition into the labor market,” Preinfalk explained.

Innovation and Sustainability

In addition to fostering talent, Siemens offers industrial digitalization and sustainability solutions. These include technologies for decarbonization and energy efficiency, designed to connect the physical and digital worlds and make industries more efficient and competitive.

130 Years of Legacy in Mexico

With over 130 years in Mexico, Siemens has left its mark across multiple sectors, from lighting Paseo de la Reforma and introducing the first electric train to advancements in industrial automation and healthcare equipment. The company’s impact has been particularly notable over the last two decades, driven by the North American Free Trade Agreement (NAFTA).

Through these initiatives, Siemens reaffirms its dedication to digital transformation and sustainable development, positioning Mexico as a key player in the era of modern industrialization.

Standardizing and digitalizing processes to increase production efficiency, reduce waste and enhance data quality

Industry: Consumer products & retail

Leveraging an Established and Trusted Reputation

Bags, including garbage bags, plastic films, and tube covers, are essential products in daily life. They are used in most households and many industries, such as food, beverages, retail, and construction. Based in Środa Wielkopolska, Poland, Polipak Sp. z o.o. is a leading manufacturer in Central and Eastern Europe and is part of the Sarantis Group, which has built a reliable and recognized brand trusted by millions of consumers. Known for its wide range of products, including both standard and customized solutions, the company plays a key role in the market, specializing in the production of various plastic film products.

Digitalization for Dynamic Growth

The Sarantis Group places great importance on sustainability as a key element of its business strategy. As a result, Polipak is continuously striving to improve production efficiency, reduce costs, and minimize its environmental impact, all while maintaining the highest quality of its products, which is its main differentiator in the market.

To continue improving its processes and strengthen its position in the market, Polipak needed systems that could comprehensively manage production processes, automate report generation, and optimize resource usage. They also needed to implement and integrate systems to ensure seamless compatibility between existing systems and the divisions of the Sarantis Group, which operates across various regions worldwide.

With the rapid growth in production volume and the increasing number of machines, Polipak had to adopt more advanced planning and management tools. Traditional methods, such as manually completed data sheets, proved inefficient in addressing the challenges of production efficiency and resource optimization.

To achieve this, Polipak partnered with ASKOM, a Siemens Digital Industries Software partner, to implement Opcenter™ for advanced planning and scheduling (APS) and as a manufacturing execution system (MES). Additionally, Opcenter is part of the Siemens Xcelerator platform, which integrates software, hardware, and services.

“We needed a solution that would provide traceability and control at every stage of production,” says Andrzej Migda, IT systems consultant at Polipak. “Our goal was to integrate modern digital solutions to better manage the complex production process across multiple stages. So, we later integrated Siemens APS and MES, which became crucial for the company’s growth.”

Optimizing Processes and Minimizing Waste

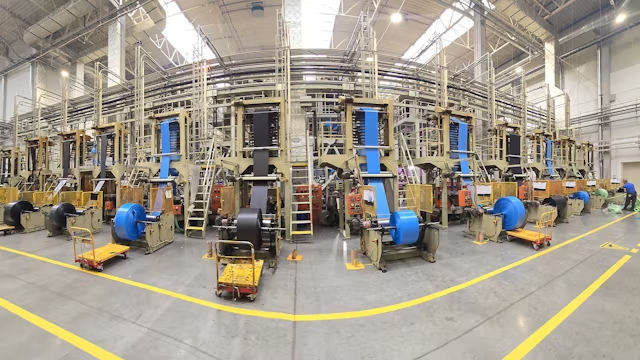

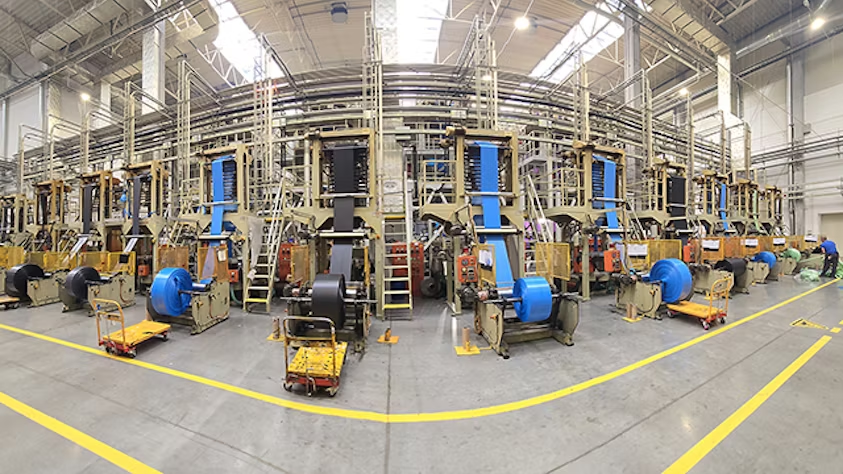

The three key areas of the company—Film Department, Roller Department, and Regranulation Department—as well as the central dosing system, are closely interconnected as part of a multi-stage production process. It starts with a fully automated process for preparing batches of raw material mixtures, which include a dozen raw materials, additives, and dyes for each extruder separately, including three-layer machines for each screw in the central dosing system.

Once the raw material feeding process begins, the film is produced on extrusion machines, rolled into rolls, and then transported to the film warehouse. When film is needed to produce bags, it is transported to the Roller Department, where finished products are made. These film and bag production processes generate waste. Although Polipak has significantly reduced waste, at current production levels, they generate around 5,000 metric tons annually. Such a large quantity requires efficient recycling to be reused in the production process.

When it began implementing customized digital solutions from Siemens, Polipak was already operating with a production facility equipped, among other things, with 67 extruders (including three and two-layer extruders, totaling 95 screws) in the Film Department, 32 machines in the Roller Department, automated packaging lines, machines to produce regranulate (a type of plastic made from recycled materials) from waste, and a central automated dosing system to supply raw materials to the extruders.

Advanced production planning and management tools, suitable for their large and growing scale of operations, were essential to ensure the smooth running of the system. With Siemens solutions, Polipak can effectively manage its complex infrastructure and optimize production processes, purchasing, and sales, as well as minimize raw material waste.

Supporting Strategic Decision-Making

With Opcenter APS, Polipak automated production scheduling, optimizing resource usage and accelerating order fulfillment. The company replaced its previous production planning process, which was slow and error-prone, with a flexible scheduling process. This process takes into account the multi-stage nature of production, production constraints, and the availability of resources and materials, considering the lead time for raw material deliveries.

By leveraging this APS system, Polipak also accelerated the planning process and improved capacity utilization. As a result, the company is able to fulfill orders more quickly and efficiently. At the same time, the system implemented allows for flexible adjustments to changes in production, including a rapid response to machine failures or potential raw material shortages. Integration with other systems, such as ERP, MES, or the central dosing system, enables a seamless flow of information, improving planning accuracy and creating realistic production scenarios.

“Using Opcenter supports strategic decision-making, allowing us to quickly respond to changing customer needs or circumstances,” says Migda. “By monitoring production in real time, we can evaluate the progress of the plan, which is key to maintaining high productivity and minimizing downtime.”

Using Opcenter for Production Quality Management

The implementation of Opcenter Execution Process, a MES solution from Siemens, was a key step in utilizing computer systems for managing the production process. Opcenter Execution Process serves as the main system for managing production, along with other systems such as APS, ERP, the warehouse management system (WMS), the central dosing system, and a computerized maintenance management system (CMMS). By maintaining interfaces, sharing data, and conducting bidirectional real-time communications, it creates an integrated production management environment.

Before implementing the MES, production monitoring and data management were fragmented and required a lot of manual work. With the system, Polipak can accurately track the production process in real time, significantly improving transparency and control over plant operations. The system collects and analyzes machine data, allowing the company to identify potential issues before they affect production efficiency.

The use of Opcenter also enables better synchronization of operational activities, from raw material receipt to production, final packaging, and product distribution. Integrating production data with the MES system provides full visibility across the production chain, resulting in higher product quality and minimal waste. At the same time, seamless procedures for receiving products, semi-finished products, and waste into the MES system allow Polipak to track performance and quality parameters in real time and respond to issues as they arise, affecting observed performance indicators.

Additionally, the use of Opcenter Execution Process plays a key role in quality management by allowing for the monitoring of production parameters and early detection of deviations from quality standards. This reduces waste and complaints and supports continuous improvement of production processes.

Driving Corporate Sustainability

The implementation of Siemens solutions at Polipak has had a positive impact on the company’s operations, efficiency, and sustainable growth. “Thanks to Siemens’ advanced APS and MES systems, we can accurately manage our resources and production processes, which strengthens our competitiveness,” says Migda.

By continually improving resource management, Polipak increased the proportion of regranulate in production from 30% to 90% over the past few years. This increase is the result of a strategic approach to raw materials, which includes not only purchasing regranulate and processing their own production waste but also buying clean post-production waste from the market. Thus, waste that was once sent to landfills is now used as a valuable raw material, supporting the company’s environmental performance.

The strategy to increase the proportion of regranulates in production requires ensuring the appropriate quality of raw materials. In response, Polipak plans to implement an automated waste washing plant by the end of this year, which will enable the company to produce regranulate even from lower-quality waste. Furthermore, by using Opcenter, Polipak has better traceability to ensure that all recycled waste and materials are properly assessed and used in production.

New NX Community for Experts in Mexico: Exclusive Webinar Series with Top CAD, CAE and CAM Specialists

Goaltech Engineering Solutions is proud to present its new NX Community for Experts, a unique training platform in Mexico that will provide exclusive access to a series of specialized webinars in the areas of CAD, CAE and CAM. Aimed at advanced professionals in the use of NX, this community is designed for those who wish to hone their skills and update themselves with the latest trends and best practices from the top experts in Mexico.

Bimonthly Webinar Series

This exclusive series will kick off with a first session on November 13 at 10:00 a.m. (CDMX time) at Microsoft Teams, and will continue with new webinars every two months, where different aspects of NX will be addressed in depth. Each session will focus on specific design (CAD), analysis (CAE) and manufacturing (CAM) topics, allowing attendees to immerse themselves in high-value technical content and share experiences with nationally recognized experts.

Access to the Best Specialists

With the support of Goaltech Engineering Solutions, Siemens Partner of the Year in Mesoamerica, the community will have the support of the most experienced NX specialists in Mexico, who will share advanced strategies, practical demonstrations and answer live questions to guarantee a dynamic and enriching learning experience. This initiative seeks not only to offer quality training, but also to build a collaborative network among advanced engineering professionals in Mexico.

The NX Community for Experts is an unparalleled opportunity to stay at the forefront in the use of NX and strengthen capabilities in each specialty. Don’t miss the opportunity to be part of this network of experts, where learning and professional growth are our priority.

Register and secure your place in the first session of this webinar series!