Industry: Manufacturers of water conveyance systems

In the infrastructure sector, where full asset replacement is often impractical, technology becomes a key ally to extend the lifespan of legacy tools. This is the case for Saint-Gobain PAM Canalisation, a company with over 160 years of history, which found in 3D scanning an effective solution to preserve its industrial legacy and move confidently into the future.

An Industrial Legacy Facing New Challenges

Saint-Gobain PAM Canalisation, part of the Saint-Gobain Group, is a global leader in manufacturing ductile iron pipes for water transportation, sanitation, and industrial applications. Founded in 1856, it has continuously evolved to meet market demands, remaining at the forefront of innovation.

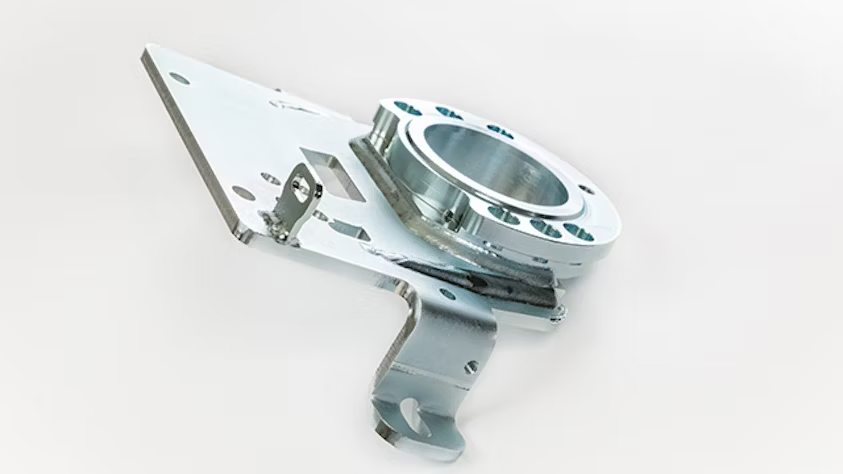

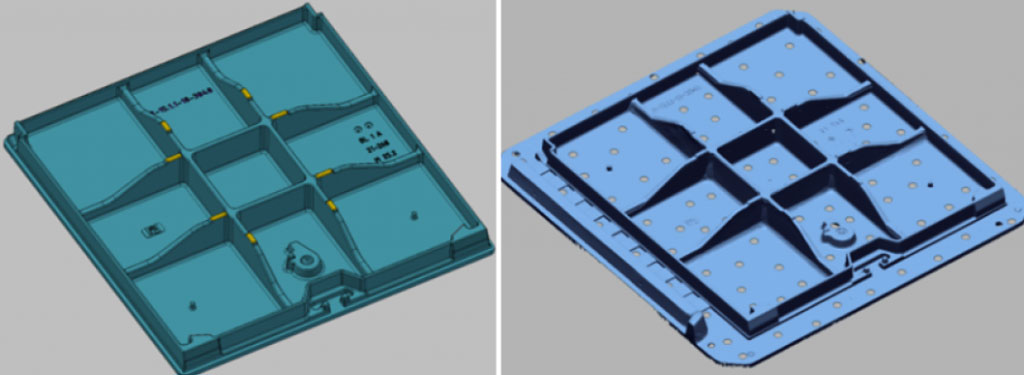

One of its current key challenges is digitizing old mold tools, essential for manufacturing plates used in road systems. These tools often lack CAD design files or modern technical documentation. However, a full replacement would involve high costs and operational complexity. The solution: accurately capture their geometry and generate reliable 3D models for reuse.

Creaform Technology: Precise, Fast, and Reliable

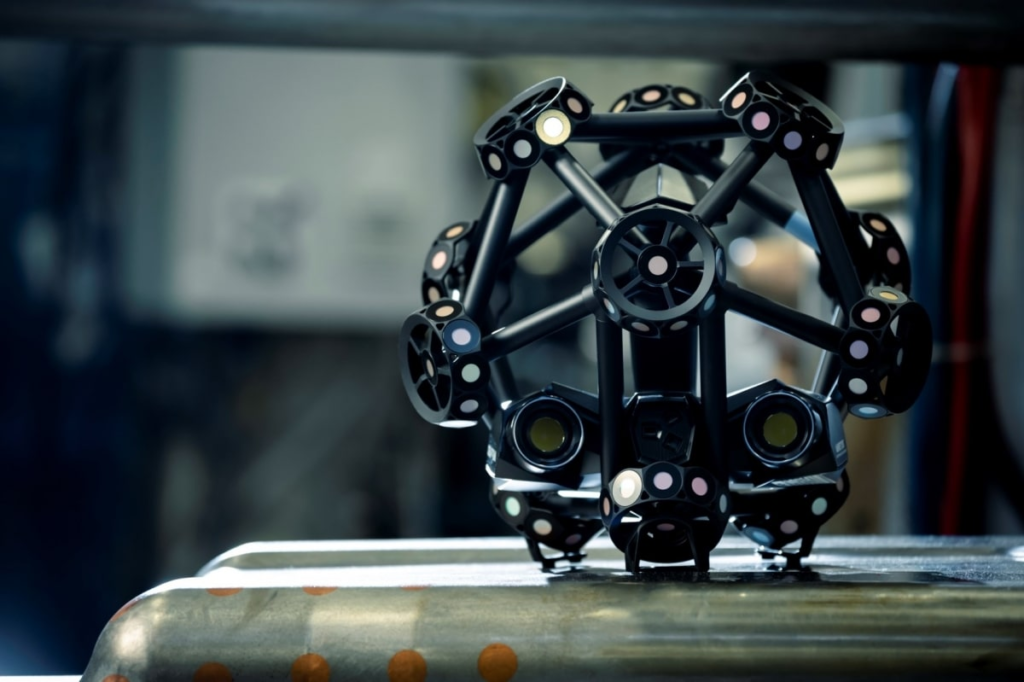

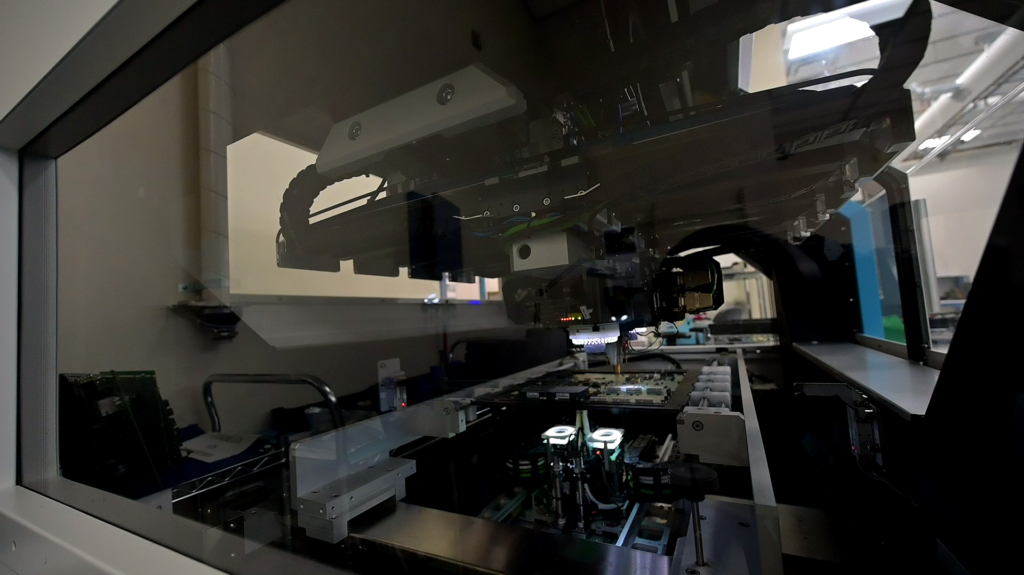

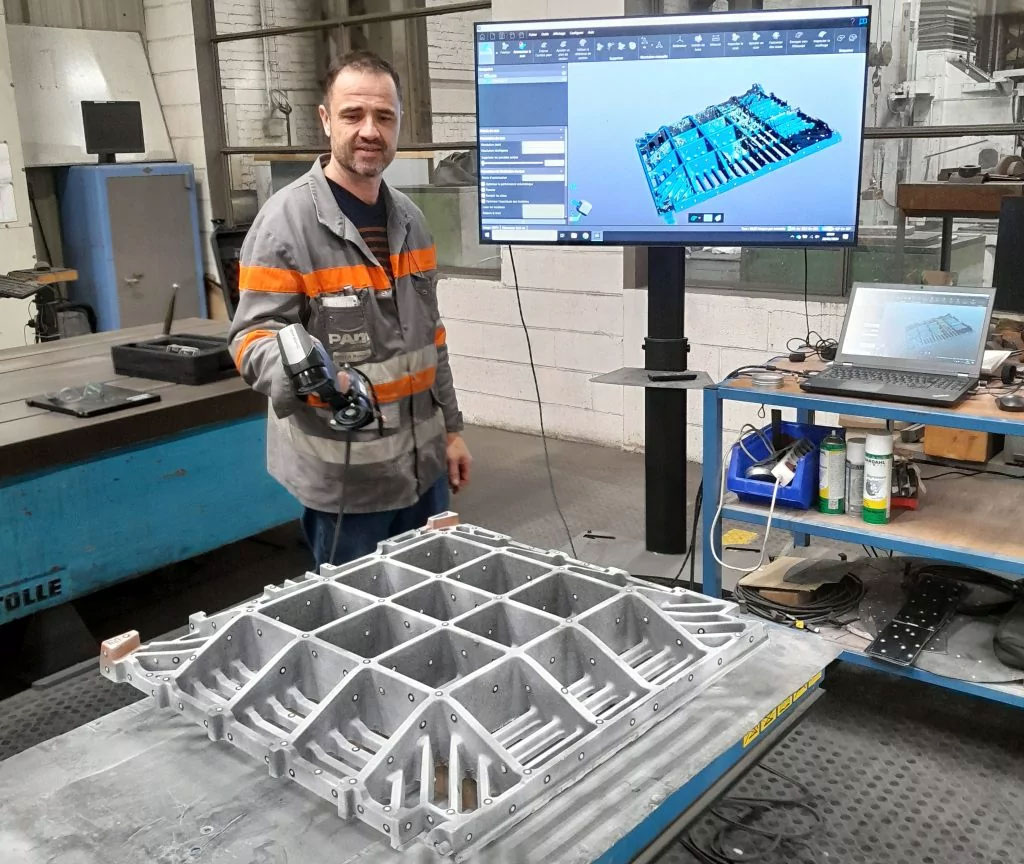

To address this challenge, PAM turned to Creaform solutions, specifically the HandySCAN 3D|BLACK scanner, known for its metrological accuracy, portability, and ease of use. This technology allowed them to capture every detail of the legacy tools and convert them into digital models with complete fidelity to the original design.

Before implementing this solution, PAM relied on traditional measurement methods, including coordinate measuring machines (CMM). However, the process was slow, error-prone, and inadequate for efficiently capturing complex geometries.

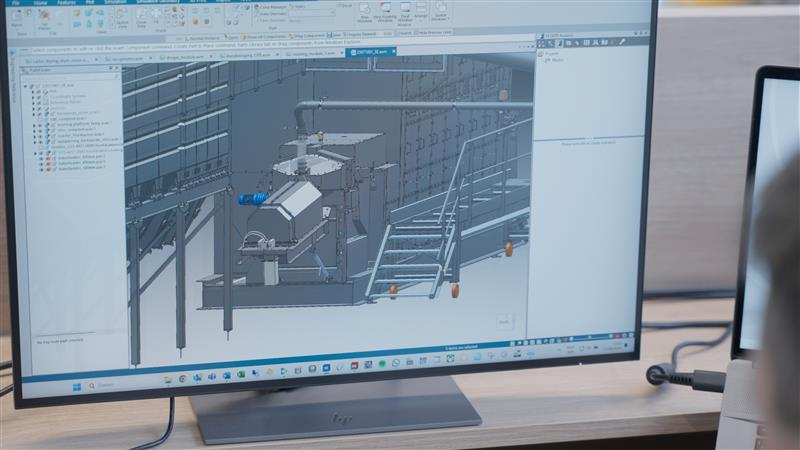

With the new system, they implemented a complete scanning ecosystem, including:

- A dedicated room equipped with a rotary table and a 75-inch monitor.

- A portable PC for flexible scanner use across production, quality control, and maintenance.

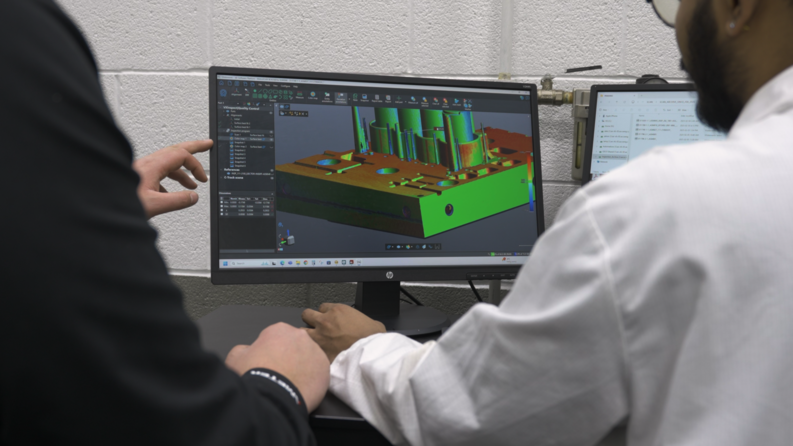

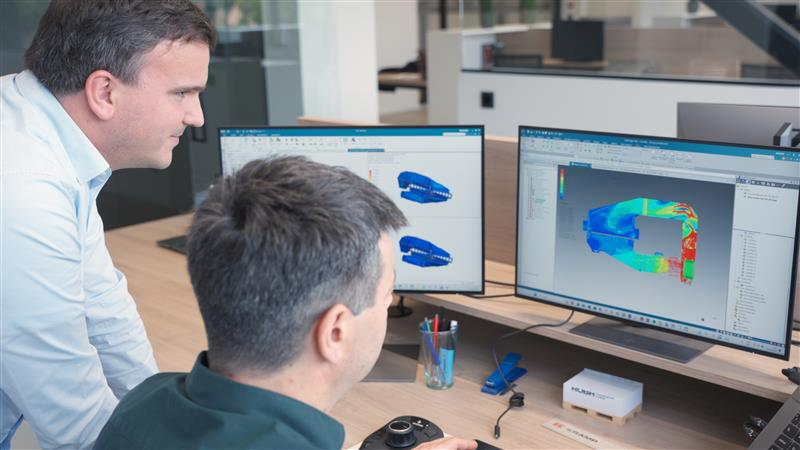

- Integration of the scanner with Geomagic Design X and Control X software for reverse engineering and quality control.

Transformative Results

The implementation of 3D scanning had an immediate impact on PAM’s processes:

Significant Time Reduction

A project that previously required 2 to 3 months with manual methods can now be completed in just 2 weeks. Thanks to the HandySCAN 3D|BLACK’s 11 crossed lasers, data acquisition is rapid, even on shiny or reflective surfaces, without needing matte sprays.

Higher Precision and Access to Complex Areas

The scanner captures precise data in hard-to-reach areas such as deep cavities, which was not possible with previous technologies. This enables much more accurate and reliable modeling.

Portability and Ease of Use

The system is used by various departments, whether in the scanning room, workshop, or on-site, expanding its applications and improving team collaboration.

Operational Savings and Mold Reuse

Beyond saving time and reducing errors, digitization allows for reusing existing tools, representing significant savings in manufacturing and maintenance.

Conclusion: Moving Forward Without Leaving What Works Behind

The Saint-Gobain PAM Canalisation case shows that it is possible to advance digitalization without losing the value of accumulated experience. Thanks to Creaform’s 3D scanning technology and integration with advanced software tools, the company has successfully preserved its industrial heritage and enhanced it with efficiency, precision, and a forward-looking vision.