Industry: Bicycle

It all started in the red barn

The Trek Bicycle Corporation was started in a small red barn in rural Waterloo, Wisconsin in 1976. There were five welders on staff the first year, who produced just over 900 steel touring frames for the firm’s first customers. Since then, the company has grown to thousands of employees in Trek stores, testing facilities and offices around the world. A lot has changed since those early days, except for Trek’s commitment to its founding principles to build great products and make the world a better place to live and ride.

Now Trek resides in a world-class research and development (R&D) facility a mile up the road from the red barn. From there it engineers and builds bikes and gear for riders around the world, from first-time riders to the professionals on the teams Trek owns that race in the world’s biggest events such as the Tour de France.

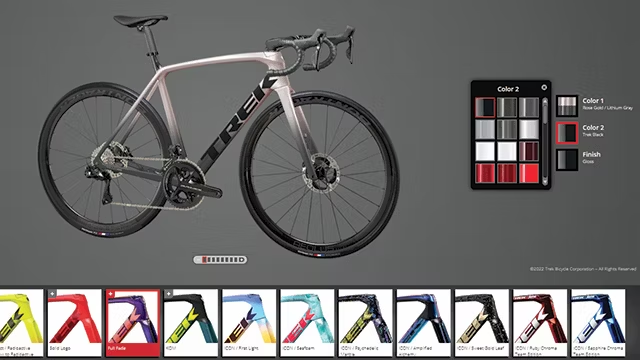

Project One

Trek’s Project One is a program that gives customers control over designing the road, mountain or electric bike of their dreams. If a customer can imagine it, Trek can make it a reality in its Project One paint shop. Project One customers have the option to choose from a pre-set combination of custom colors, paint schemes and components, or dream up a wild idea for a unique bike.

The manufacturing, painting and building of Project One bikes is performed at the Waterloo headquarters and the facility in Hartmannsdorf, Germany. Trek also manufactures the high-end carbon wheels for the custom bikes in Waterloo.

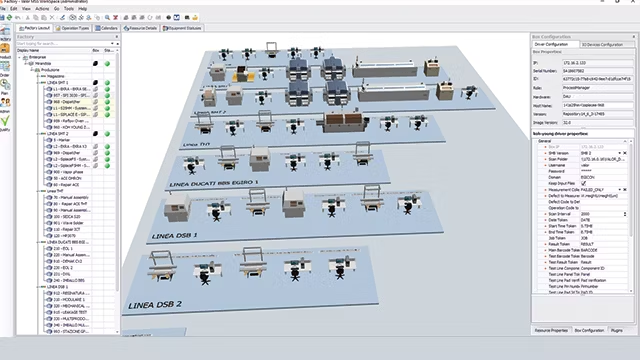

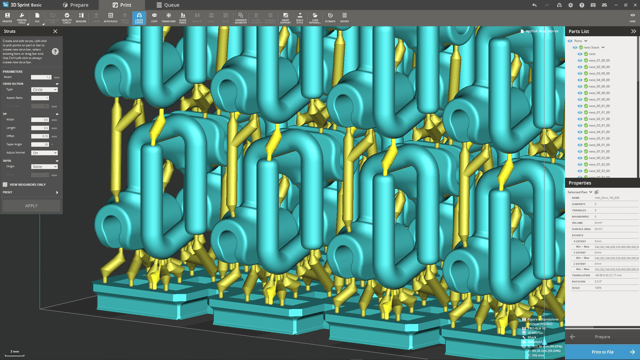

Trek has made the custom bike process streamlined, fast and easy for customers, taking every action they can to minimize lead times. That has been a challenge when there are parts shortages, but Opcenter™ software, which is part of the Siemens Xcelerator business platform of software, hardware and services, has enabled Trek to see the full picture, prioritize components for customer bikes and allocate parts to build in the most efficient way possible.

“Thanks to Opcenter Advanced Planning & Scheduling, we are able see in advance that we are going to have the parts available to build twice as much as was previously possible,” says Eric Schultz, master scheduling manager at Trek.

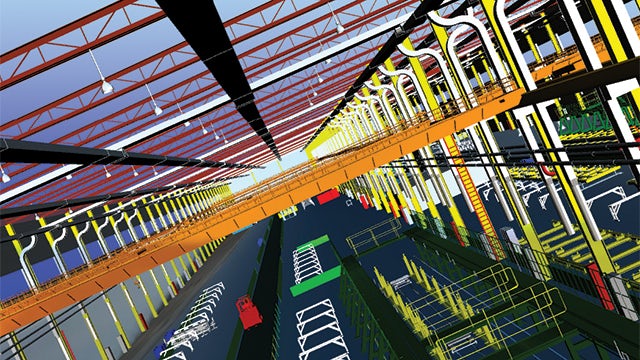

Digital transformation supports build-to-order

The Trek Project One program is a high-mix, low-volume, build-to-order business. Its increasing reliance on digital tools provides the best experience for its customers and partners. When a customer places an order, a production date is generated based on the availability of parts and capacity at the time of the order. Trek forecasts the components they need to buy based on what they think the customer preferences will be, rather than purchasing components for a fixed amount of production by model.

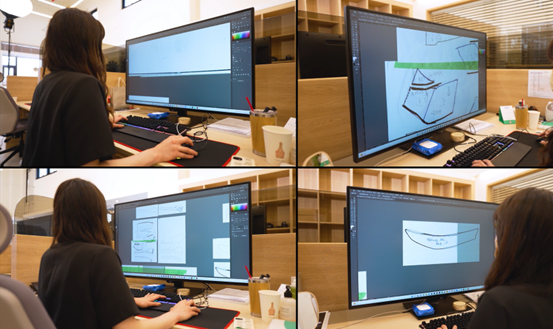

Trek’s digital transformation enables the customer to design their dream bike on a screen, place their order through their local bike shop, get an estimate on a lead time, obtain email/photo notifications during the paint and build process, and ultimately realize their concept in physical form.

“Previously, we used SQL reports and standard features in our ERP system that worked just fine on a smaller scale, but on a larger scale it just wasn’t tenable,” says Mike Lodl, director of global manufacturing. “We knew with continued business growth the current process wouldn’t be sustainable without adding more and more schedulers.”

The limitations of the existing way of working meant Trek could not test any new scenarios, do any longer term capacity analysis as supply chain issues arose, and move work order dates and sales order dates, which was a time-consuming manual process that limited growth.

Optimizing lead times

For Project One, using Opcenter enables Trek to get real-time information, marry it with part and capacity availability and deliver a top-notch bike to their customers and dealers in the shortest possible time while being as transparent and helpful as possible along the way.

“The dynamic calendar in Opcenter really helps us optimize our lead times for our customers based on how we are working and operating in each of our departments,” says Schultz.

Prior to the pandemic, Trek faced normal supply chain and inventory issues such as delays, nonconforming materials, natural disasters impacting delivery or a variety of other logistics issues. When a key component was delayed, Trek had to manually move hundreds or thousands of work order and sale order dates, then they had to find work to fill the schedule back up to keep the plant running.

“This was an incredibly time-consuming and manual process,” says Schultz. “Being a necessary, but nonvalue-added process, we knew we should try to automate or speed the process up with some type of software solution.

“There wasn’t an efficient way to expedite work or plan production if our supply chain and logistics team were able to get components in earlier.

“There were days I was spending hours manually entering dates, but now thanks to Opcenter I can use my time to do analysis or find other ways to optimize our business. Opcenter frees up hours of my time for higher added-value tasks.”

Seeking sustainability

One option was a mass data upload process, but that wouldn’t provide the analysis or intelligence Trek needed. The company reviewed several software solutions, but in the final analysis determined Opcenter was the right choice.

“Ultimately, we knew that Opcenter Advanced Planning and Schedule software was going to be the solution,” says Schultz.

“When we stated what the scope of the work was going to be, or what we wanted the software to do for us, Siemens preferred partner SNic was the only company out of three that told us, ’Yes, we’ve done that with Opcenter for other customers.’ We even spoke with other users who confirmed that they were using Opcenter in the same way we wanted to for our business.

“The combination of the software and the SNic’s expertise was unique. The team understood our challenges and were partners in developing the custom logic solution specific to our business, and Opcenter stood out for its out-of-the-box options and functionality. We also liked the fact that Opcenter had been used more widely in the industry than the other products we evaluated.”

The Opcenter advantage

According to Schultz, “Opcenter automated a lot of work. Our scheduling team would spend hours updating thousands and thousands of work order and sales order dates each time we discovered a supply issue that we couldn’t resolve. Opcenter freed up the scheduling team to do more analysis instead of spending time changing thousands of dates.

“Opcenter can help us understand what we will have components for to build in each department over time. This helps us understand where we may need to train or hire employees.

“We can manage more than twice the amount of work we used to with the same size team and we’ve avoided countless production shutdowns to ensure employees remained gainfully employed in production.”

Lodl states, “For Trek customers to be able to have the experience of getting their dream bike months ahead of time has made their buying experience outstanding.”