Siemens

How Pierre Fabre Is Advancing Sustainable Water Management with Siemens Digital Twin Technology

Industry: Pharmaceutical

Pierre Fabre, one of France’s leading pharmaceutical and dermo-cosmetic companies, faced increasing pressure to enhance the sustainability of its water management practices without compromising operational reliability. Today, managing water resources has become more complex than ever, especially under strict regulatory requirements and the need for transparent, real-time operations.

The Challenge: Balancing Sustainability and Operational Continuity

Organizations must strike a delicate balance between meeting environmental goals and maintaining efficient production. For Pierre Fabre, traditional approaches based on static planning and reactive adjustments were no longer sufficient. These methods could not handle the interplay between production demands, seasonal water availability, and regulatory constraints.

To address these challenges, the company partnered with Siemens and Institut Mines-Télécom in a research initiative centered around digital twin technology.

The Solution: A Calibrated, Strategic Digital Twin

A well-calibrated digital twin is key to transforming water management. This technology enables precise short- and long-term simulations of water usage and provides a clear understanding of how operational decisions will play out.

Additionally, scenario-based investment analysis helps prioritize the most effective and sustainable actions, ensuring alignment between environmental and business objectives.

Advanced Simulation and Forecasting

By developing a digital twin of its water management system using Siemens Plant Simulation and Optimize My Plant, Pierre Fabre created a virtual model that mirrors real-world parameters. This allowed the company to:

- Simulate multiple operational scenarios under real constraints

- Forecast daily and seasonal consumption patterns

- Identify structural improvements to significantly reduce water usage

- Make smarter, data-driven investment decisions

Early results showed strong potential: the company uncovered clear opportunities to optimize consumption and pursue investments that balance economic priorities with environmental responsibility.

Value Across the Organization

The digital twin delivers value at multiple organizational levels. First, it provides simulation capabilities to understand and resolve operational challenges. Then, by integrating real-time data, it enables both proactive and reactive supervision.

“The digital twin provides answers at all levels within organizations. The first level is simulation to understand and solve operational issues. Next, the integration of real-time data enables proactive and reactive supervision.”

— Christophe Rousse, Operations Data & Analytics Director at Pierre Fabre Group

Looking Ahead

Pierre Fabre plans to evolve its digital twin into a fully supervised system capable of dynamically adjusting water usage and strengthening its sustainability commitments. This use case demonstrates how digital twins are guiding the pharmaceutical industry toward smarter, greener production.

It also highlights the importance of Siemens’ simulation expertise and academic collaboration in solving real industrial challenges.

Goaltech, recognized by Siemens as a success story in industrial digitalization

An article was published on the official Siemens Digital Industries Software website that fills us with pride: Goaltech was highlighted as a success story for its role in the digital transformation of Mexican industry. This mention reinforces our commitment to innovation and the adoption of technologies that drive competitiveness in key sectors.

What does Siemens highlight in its article?

The case study describes how Goaltech, as an authorized Siemens partner, has supported Mexican companies in implementing solutions that optimize processes and reduce costs. The publication highlights our expertise in tools such as Tecnomatix, NX, Solid Edge, and Valor, which are essential for improving efficiency in electronics manufacturing and automation.

Impact on the industry

The official article emphasizes that our collaboration with Siemens is not only focused on software sales, but also on technology integration and specialized training, helping our customers face challenges such as reducing time-to-market and migrating to more agile and digital processes.

Read the full article on the official Siemens website:

https://resources.sw.siemens.com/en-US/case-study-goaltech/

Thank you for joining us on this journey

At Goaltech, we are proud of this recognition from Siemens, which reflects our commitment to innovation and technological excellence. We invite you to learn more about our solutions and how we can help your company take the next step toward digitalization.

Crucianelli: Digital Engineering to Transform Agricultural Machinery

Industriy: Agricultural machinery.

Crucianelli, an Argentine manufacturer of seeders with nearly 70 years of history, has embarked on a deep digital transformation with the goal of becoming one of the top five seeder manufacturers in the world by 2030. To achieve this, the company adopted the full Siemens Xcelerator portfolio, redefining its design, simulation, and manufacturing processes.

From Family Workshop to Innovation Leader

Founded by Don Nazareno Crucianelli in Armstrong, Santa Fe, the company began as a small workshop repairing agricultural machinery. Today, under the leadership of the third generation, Crucianelli blends tradition, sustainability, and technology to tackle modern agricultural challenges such as climate change, labor shortages, and the pressure to increase productivity sustainably.

The Solution: Siemens Xcelerator

With support from partners Simecanic / X-Plan and Descar Argentina, Crucianelli implemented a comprehensive solution based on:

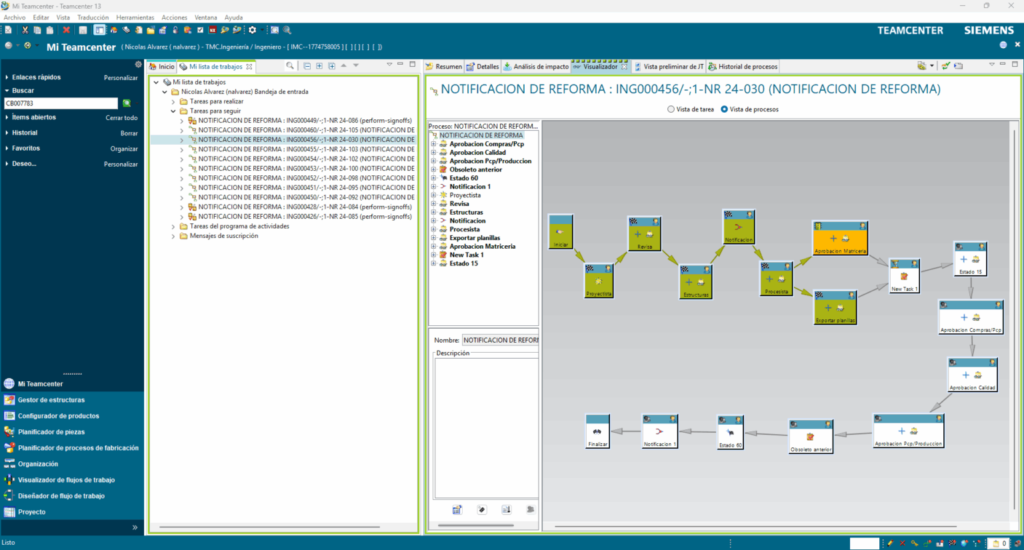

- Teamcenter as the PLM backbone, integrated with SAP.

- Simcenter 3D for structural and motion analysis.

- Designcenter NX for advanced CAD design.

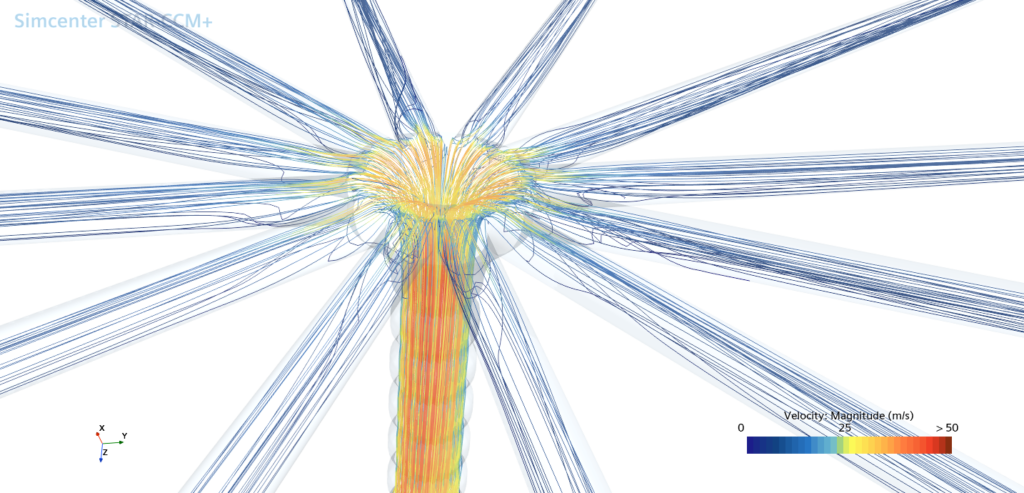

- Simcenter STAR-CCM+ for CFD-DEM simulations of seed distribution systems.

- Tecnomatix Plant Simulation to digitize manufacturing processes.

Flagship Project: The Dómina Seeder

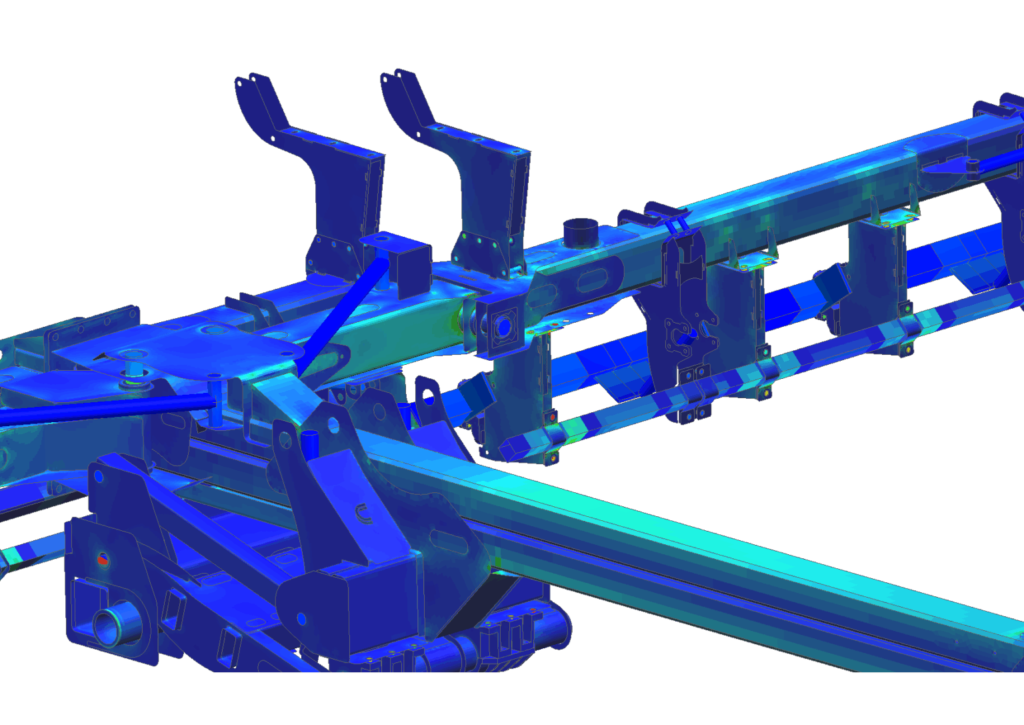

The Dómina is Crucianelli’s first seeder developed entirely in a digital environment. The engineering team built a FEM model with over one million elements (1D, 2D, and 3D), simulating transport and field conditions. With Simcenter 3D, they optimized load distribution, validated structural integrity, and significantly reduced the need for physical prototypes.

A dual-track simulation strategy was applied: one team focused on motion analysis, while another handled structural validation. The integration between NX and Simcenter enabled early design decisions and faster iterations.

Key Results

- Over 40% reduction in development time and physical testing.

- Complete digitalization of design, manufacturing, and product configuration.

- Performance optimization of new and existing machines, such as the Plantor, using CFD-DEM simulations in STAR-CCM+.

Beyond Design: Digitizing the Factory

Crucianelli is also digitizing its production plant using Tecnomatix Plant Simulation, aiming to optimize processes, logistics, and resources. The long-term goal is to replicate digital twin capabilities across the entire organization.

Training and Knowledge Transfer

Success was also driven by a strong training strategy. Young engineers were trained in structural modeling, mesh reduction, and result interpretation, while preserving the hands-on knowledge of experienced technicians. This combination strengthened the company’s innovation culture.

A Collaborative Ecosystem

The collaboration between Crucianelli, Siemens, and local partners was key. The integration of Teamcenter with SAP, automation of product configurations, and ongoing technical support enabled Crucianelli to accelerate innovation and improve competitiveness.

Conclusion

Crucianelli shows how a family-owned company can lead digital transformation in the agricultural sector. With Siemens Xcelerator, it has improved internal efficiency and developed more robust, precise, and field-ready products.