Industry: Water pumps

Enhancing water movement and management technologies

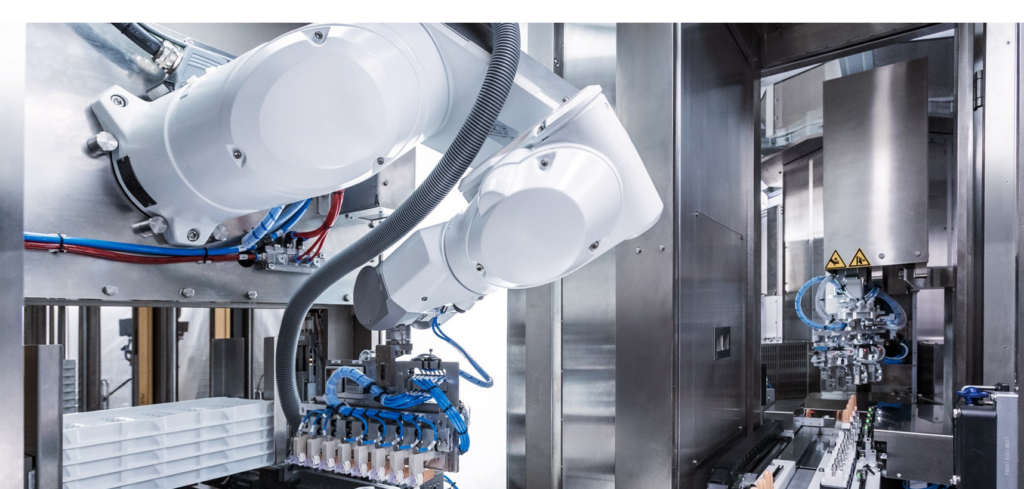

Founded in 1975, DAB Pumps S.p.A. (DAB Pumps) is a multinational organization with seven production sites, 12 sales branches and a total workforce of more than 1,500 that specializes in water movement and management technologies. The distinguishing features of DAB Pumps technologies are reliability, quality and efficiency. The aim is to identify simpler installation, and use and maintain solutions for domestic, residential, civil and commercial applications as well as agricultural irrigation systems.

Siemens facilitates digital transformation

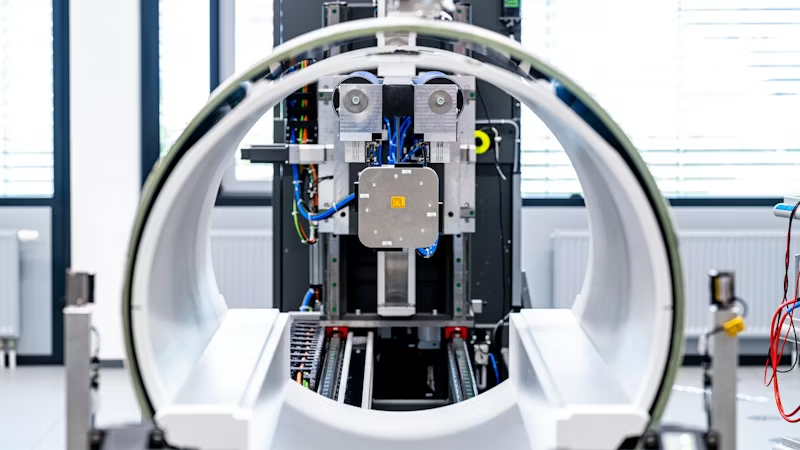

DAB Pumps refers to their digital transformation strategy as the DAB Digital Evolution (DDE). The DDE supports a new digital strategy that links DAB Pumps’ values to new digital opportunities.

“We are working to build an open-minded digital culture, developing innovative and engaging projects and designing solutions in which technology works for people,” says Sandro Stramare, group chief executive officer (CEO) of DAB Pumps.

According to Paolo Menon, group chief operation officer (COO) of DAB Pumps, “Our factory of the future represents an important step to close the loop between our customers and factories. It’s a way to interconnect all the elements that create value and is an effective end-to-end process that supports a new set of services and connected products to transform the customer experience.”

Looking to facilitate a successful digital transformation, DAB Pumps benchmarked multiple software solutions by using a digital sourcing evaluation to find the best fit for their company. After an exhaustive search, DAB Pumps decided the Siemens Digital Industries Software Manufacturing Operations Management (MOM) portfolio of solutions best suited their needs.

“We scanned many solutions in the market and we came to Siemens because we think the most important dimension is the willingness to become a partner and not simply a supplier,” says Enrico Pana, group logistic manager and digital manager for operations, DAB Pumps. “Siemens is meeting our expectations in terms of integration with third-party systems, discrete manufacturing features and standard solutions.”

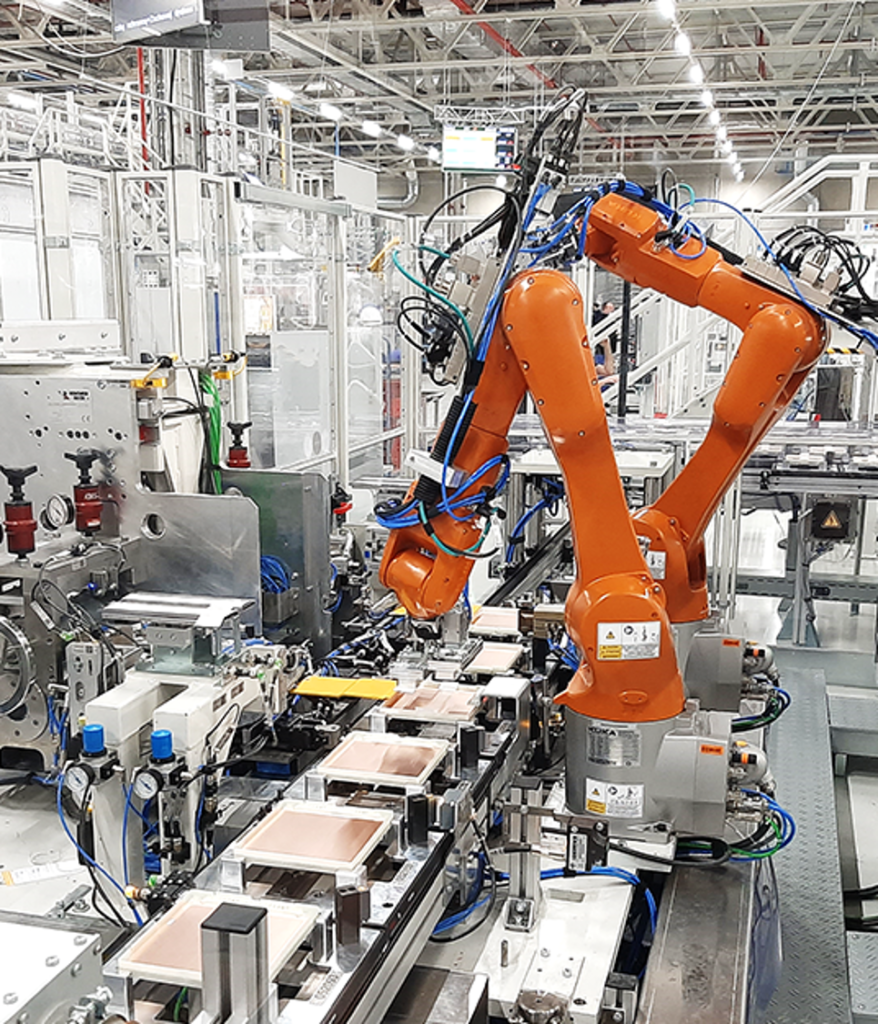

DAB Pumps manufactures what the customer wants, and in order to have the best time-to-market and connected products in the market, they adhere to the lean production method of minimizing waste without sacrificing productivity.

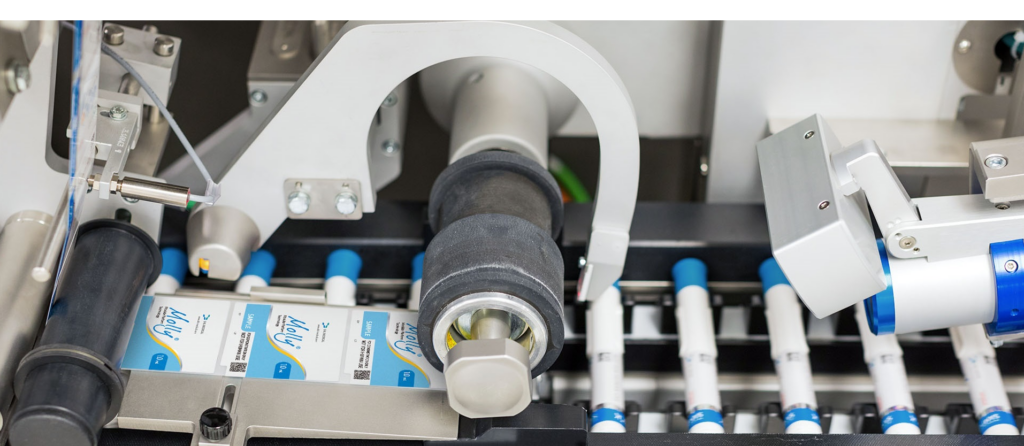

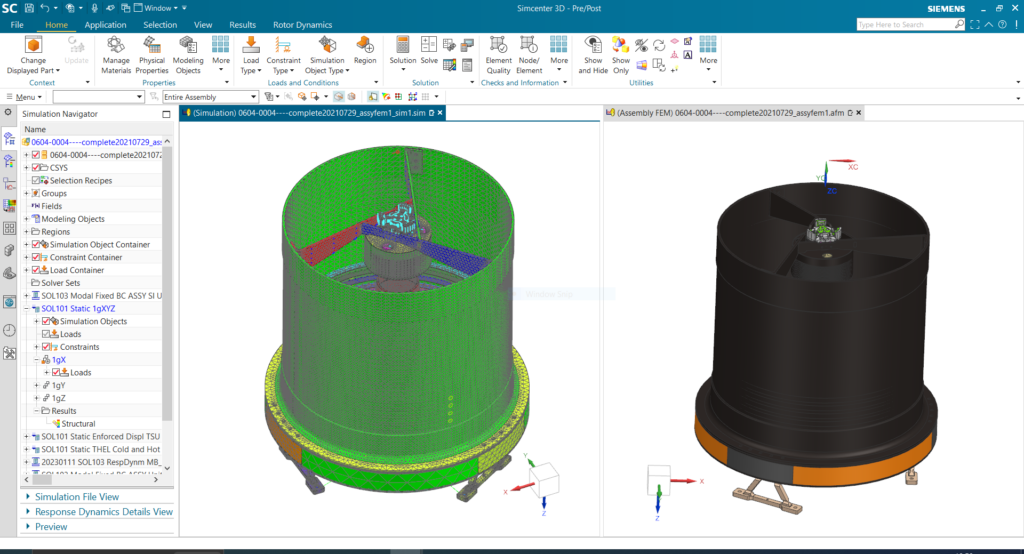

The Siemens solution, Opcenter Execution Discrete, helped change the manufacturing process for DAB Pumps. It allows them to track every step of their product process, serialize each water pump and introduce better control/visibility of management over production process and paperless manufacturing.

Additionally, DAB Pumps employs Siemens’ Opcenter Intelligence and Opcenter AS to make their processes more efficient through effective resource utilization.

Opcenter Intelligence is used to precisely map DAB Pumps’ production process by providing a centralized system integrated with business functions to eliminate paper usage while improving visibility and control over production process/data. Using Opcenter AS allows DAB Pumps to more efficiently manage their production plan in order to support their clients’ changing needs.

The Mestrino plant, (Dab Pumps Headquarter).

Business and technical challenges

DAB Pumps faced major business challenges in managing production and satisfying their clients’ fluid requirements. The company identified two reasons for these challenges: First, there were difficulties sharing information within the company, which led to a siloed approach, and second, there was limited visibility within the company into production activities.

The technical challenges DAB Pumps faced were mainly due to lots of manual activities, significant use of paper and very limited availability of digitally shared data related to critical activities and performed by operators with extensive experience and skills (work instructions, test results, nonconformities). DAB Pumps was facing issues like using spreadsheet software for manual scheduling and work-in-process (WIP) management software, and manual inventory and collecting quality data by hand or that was left on automatic stations.

Benefits of Siemens’ solutions

By introducing a manufacturing execution system (MES)/MOM solution based on Opcenter Execution Discrete and Opcenter AS, the problem of siloed data was largely eliminated. That’s because there was now a bi-directional level of communication between the enterprise resource planning (ERP), product lifecycle management (PLM) business systems and the shop floor, allowing for greater and immediate control of the business on the production floor. Also, using Opcenter Execution Discrete enabled off-the-shelf support for WIP, tracking and inventory control. Further, it improved operator activities due to electronic work instructions (EWI) features and manual and automatic quality control while also facilitating creation of a centralized quality data archive. Opcenter AS is integrated with Opcenter Execution Discrete to create a proactive scheduling approach, which provided DAB Pumps with more accurate delivery dates, supply demand synchronization and effective resource utilization.

Using Opcenter AS production scheduling improves the synchronization of DAB Pumps’ manufacturing processes, providing greater visibility and control. This enables DAB Pumps to increase resource utilization and on-time delivery while reducing inventory levels and waste.

Opcenter Intelligence is used by DAB Pumps at the plant level to improve collaboration and data exchange between the plant floor and enterprise systems. As data from different sources are combined, they can be put into a new context or aggregated to provide team leaders with a different and more complete perspective of operations regardless of where the data originated.

Optimizing the entire value chain through digitalization

“Digitalization was not a matter of choice for DAB Pumps,” says Stramare. “We are adapting to what is happening at a world-wide level. DAB Pumps embraced digitalization mainly to create value within our company. We believe that digitalizing our company increases the creation of value in all company areas, and we believe that digitalization is not only an epochal change at a worldwide economic level, but it helps companies increase efficiency, and enhances and creates value in the production and sales processes. This is the main reason why DAB Pumps strongly believes in digitalization and is pushing the digitalization of its processes.”

-640x360.jpg?w=900&fit=max&q=60&dpr=1&auto=format)

-640x360.jpg?w=900&fit=max&q=60&dpr=1&auto=format)

-640x360.jpg?w=900&fit=max&q=60&dpr=1&auto=format)

-640x360.jpg?w=900&fit=max&q=60&dpr=1&auto=format)

-640x360.jpg?w=900&fit=max&q=60&dpr=1&auto=format)

-640x360.jpg?w=900&fit=max&q=60&dpr=1&auto=format)

-640x360.jpg?w=900&fit=max&q=60&dpr=1&auto=format)

-640x360.jpg?w=900&fit=max&q=60&dpr=1&auto=format)

-640x360.jpg?w=900&fit=max&q=60&dpr=1&auto=format)

-640x360.jpg?w=900&fit=max&q=60&dpr=1&auto=format)

-640x360.jpg?w=900&fit=max&q=60&dpr=1&auto=format)