Industry: Intralogistics

Experts in intralogistics and warehousing operations

Intelligent Distributed Controls (IDC) was founded in 2003 to support customers with intralogistics and warehousing operations in the U.K. and Europe. The engineering, management and IT team at IDC have a broad range of skills including HV Control Panel Design, PLC Software Development, with C# .NET and Android supporting the WCS and WMS development. The team is also supported by project managers with an in-depth knowledge of intralogistics and warehousing and advises customers on automation and warehouse control and management systems (WMS).

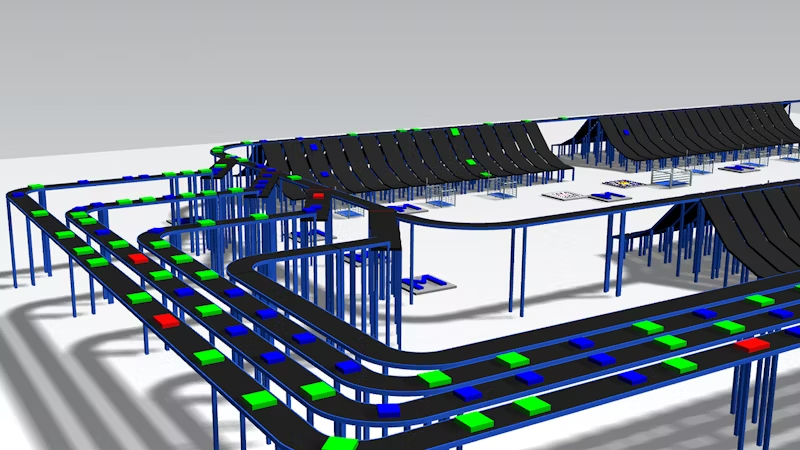

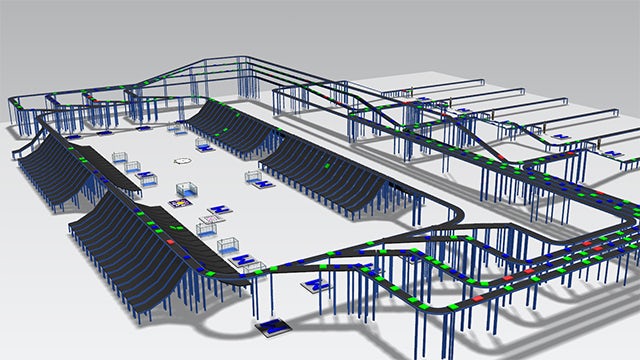

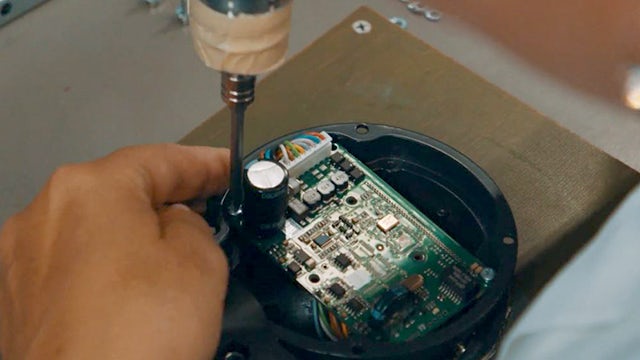

One of IDC’s customers, a retail distribution center serving major mail order and e-commerce businesses, had begun planning in spring for the upcoming Christmas seasonal peak. One of the key machines in the distribution center is a high-speed tilt-tray sortation machine that processes more than 6,000 items per hour. The customer wanted to update the machine’s systems due to unsupportable SCADA and controls systems, and asked IDC to complete the upgrade in a narrow two-month window during May and June.

Besides its short time frame, the project posed additional challenges for IDC. IDC wanted to explore how much work could be completed remotely, to reduce the time required for final commissioning checks at the customer site.

Partnership with Simsol

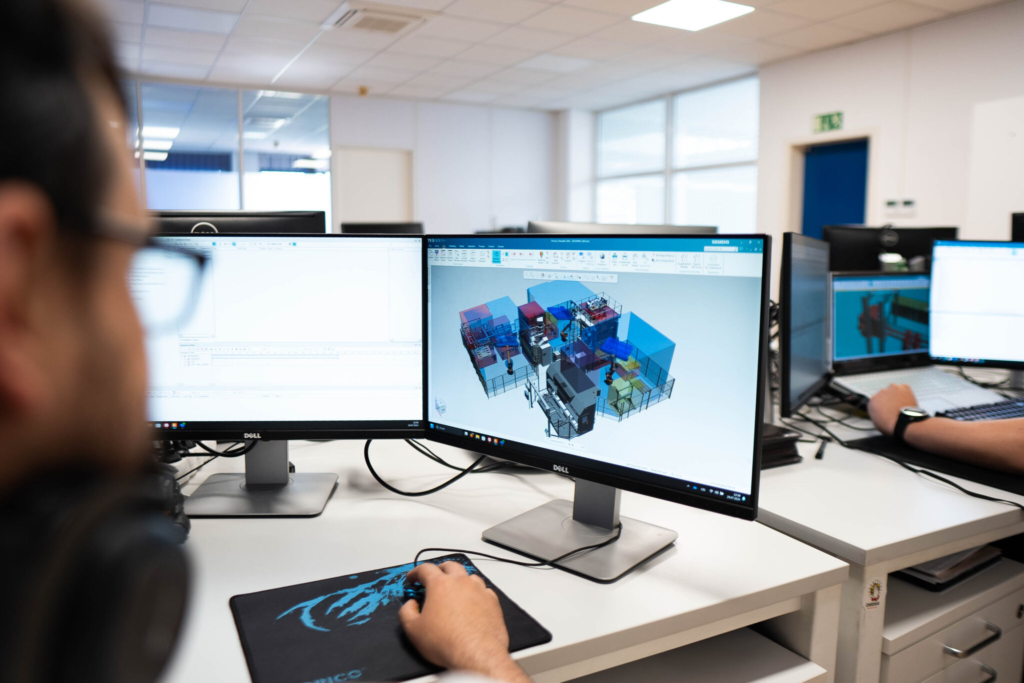

IDC decided to use a combination of virtual and on-site commissioning techniques to reduce lead time on the project, and for this purpose partnered with Simsol, a Siemens Digital Industries Software solution partner.

Simsol is focused on Siemens’ Tecnomatix® portfolio of digital manufacturing solutions, and has gained recognition as a Expert partner, providing specialized expertise in digital manufacturing technologies and production simulation. Simsol trained IDC on the Tecnomatix software and offered best-practice advice on how to use and construct its models throughout the project.

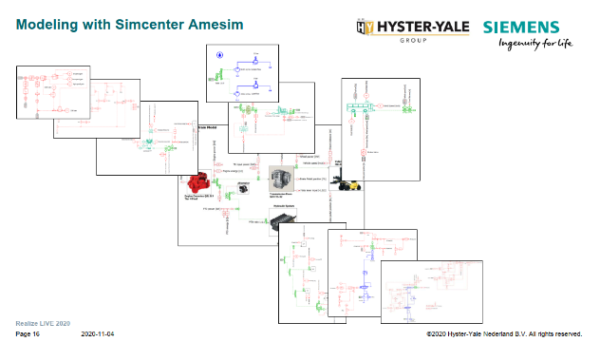

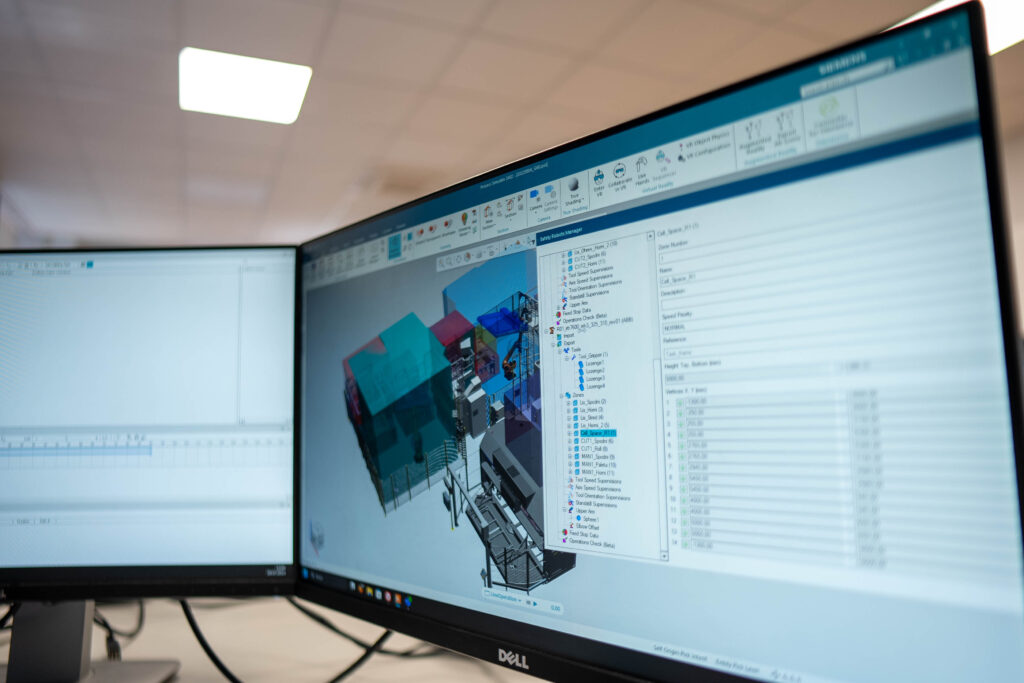

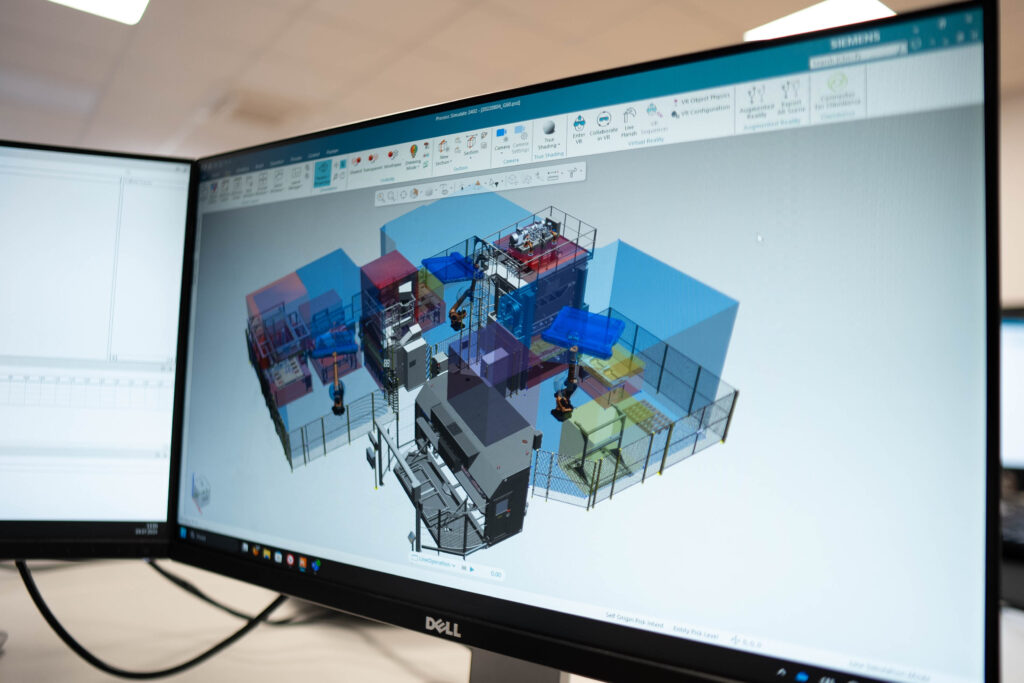

Leveraging the digital twin

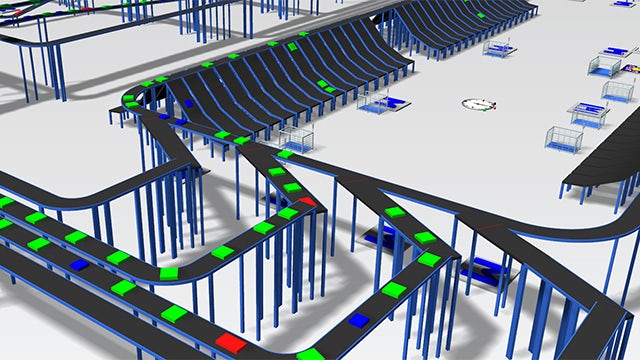

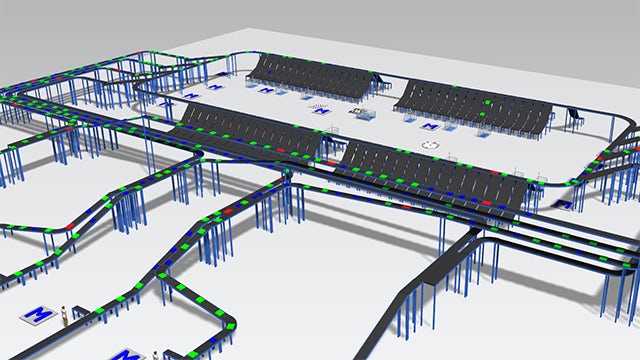

IDC used Plant Simulation in the Tecnomatix portfolio to build a comprehensive digital twin of the retail distribution center – a complete and accurate 3D model of the logistics systems and their processes, including control logic. The digital twin gives a strategic overview of the entire operation, rather than just a single cell or line. This gives more opportunity to focus on key areas identified for investigation and to continually improve across the whole production. IDC used the digital twin to explore and optimize the distribution center for performance, and to accurately simulate the tilt-tray sortation machine and more importantly the induction logic, which is critical to optimizing the throughput.

To make the most of the time available, the IDC team focused on the more complex areas of the machinery, investigating the dynamics and relationships among components and simulating mechanical changes to moving parts.

With the digital twin, the team was able to consider oversized (or “ugly”) items. Instead of building from the general throughput rate for standard items, the team generated virtual stock data in a range of item sizes that closely represented the packages to be processed by the distribution center. The dynamic data yielded a more realistic view of machinery performance. Performing this work remotely was crucial to meeting the customer’s deadlines.

“Without access to the actual sortation machinery, we had to use standard warehouse control system design models to construct code for testing,” says Richard Towne, Managing Director at IDC. “With the simulation model that IDC created, we could simulate almost all aspects and know that the code was validated against the system design, so we didn’t need major changes when we got on site.”

Tangible results

IDC realized tangible results from the use of digital twin plant simulation. The company was able to upgrade the controls and commission the tilt-tray sortation machine in just five weeks, well within the time frame proposed by the customer. With remote commissioning, IDC also minimized costly on-site time, reducing overall commissioning time by three weeks as compared to a similar upgrade project that required eight weeks using on-site commissioning only. The controls upgrades also increased the throughput of the sortation machine.

-640x360.jpg?w=900&fit=max&q=60&dpr=1&auto=format)

-640x360.jpg?w=900&fit=max&q=60&dpr=1&auto=format)

-640x360.jpg?w=900&fit=max&q=60&dpr=1&auto=format)

-640x360.jpg?w=900&fit=max&q=60&dpr=1&auto=format)

-640x360.jpg?w=900&fit=max&q=60&dpr=1&auto=format)