Industry: Industrial machinery

Reducing lead times for small machined parts

YouniQ Machining was founded in November 2017 to address a severe limitation in the machining of small fixtures and parts that are primarily used for testing and measuring. The production of such parts is typically outsourced, but production facilities are not well equipped to handle the requests. Manufacturing of single pieces typically requires eight to 12 weeks when produced with conventional machining processes. In contrast, many parts can be produced with 3D printing processes that reduce lead time to only two working days. YouniQ Machining considered whether a similar lead time reduction was possible for the machining industry.

Additive manufacturing/3D printing technologies emerged in a period when online platforms were commonly accepted; the business models of most companies that offered 3D printing services was very much focused on web-based platforms from the beginning. Industrial machining is far more conservative, but after investigating the possibilities and limitations, YouniQ Machining could not determine why time to market could not be significantly reduced.

The only limiting factors the company identified were the dimensional tolerances, which are typically much lower for machining. After some research it became evident that these tolerances are almost never a showstopper: most machine shops determine tolerances based on 2D technical drawings that specify generic and excessively tight tolerance grades from the ISO system of limits and fits that result in a tight fit. Other reasons for long lead times include overloaded production funnels, a lack of skilled personnel, unnecessarily conservative processes, and material unavailability.

Solving the problem through digitalization

YouniQ Machining’s primary challenge was to create a completely new business model that would revolutionize the production of one-time or small-batch machined parts. The company abandoned traditional approaches and reimagined the entire process from scratch, from order intake, assessment, and production to delivery. The only way to achieve this new approach was to digitalize every element of the process.

Envisioning a web-based machine shop

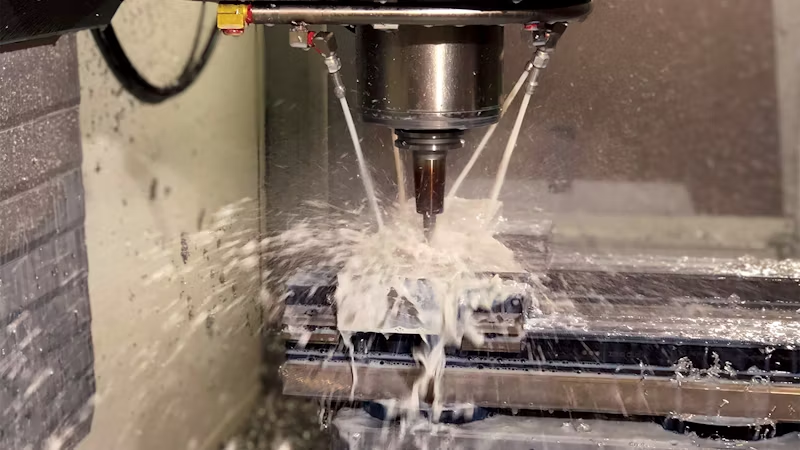

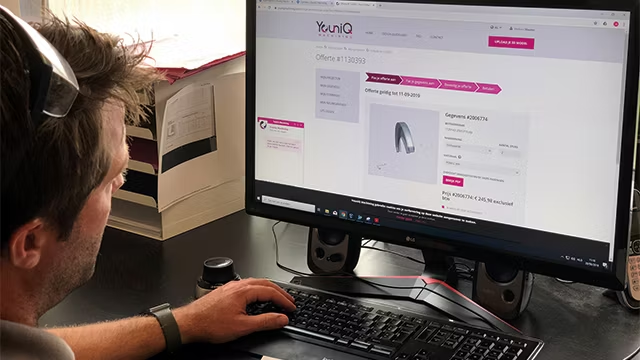

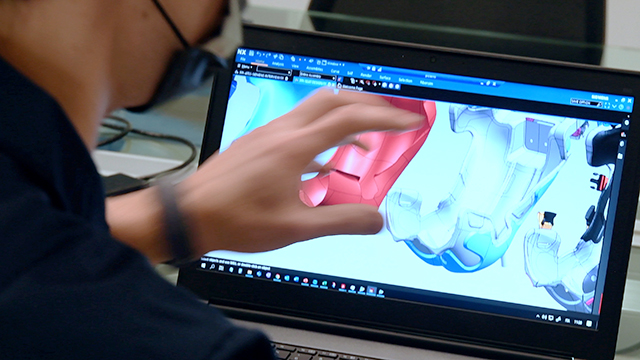

YouniQ Machining envisioned a digital workflow that could streamline and accelerate the order-to-production cycle, creating a web-based machine shop that would bring the efficiency and speed of 3D printing services to machining processes. The digital workflow begins when the customer prepares a 3D model of the desired component using any computer-aided design (CAD) program and uploads the CAD file to a web portal. Once uploaded, YouniQ applies automated routines to analyze the model’s manufacturability and generate a quote based on simulated machining time and material. The company provides the customer with a downloadable 3D model of the part showing the expected machining results, which the customer can use to verify its fit in an assembly. Customers can adjust the quote based on material, quantity, delivery, and post-machining requirements, and then place the order. Using computer-generated programs, YouniQ’s staff and modern machine shop produce the parts and arrange delivery as specified by the customer.

Unique web platform and zero-touch production approach enables next-day delivery

One of the main challenges in realizing the web-based machine shop was integrating the web environment with computer-aided design and manufacturing (CAD/CAM) solutions. Since no out-of-the-box solution was available, YouniQ had to program everything manually. A robust application programming interface (API) in the CAD/CAM solution was crucial.

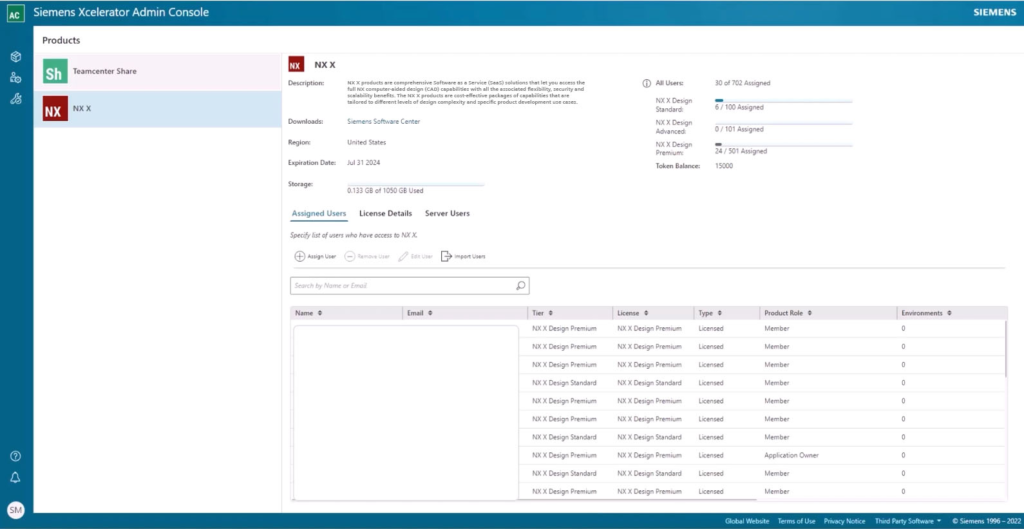

YouniQ initially worked with a CAD/CAM provider that offered good web integration, but they could not meet the API requirements. Another CAM provider had a strong API but failed in web integration and CAD capabilities. The company then partnered with Siemens Digital Industries Software, which provided solutions that met all of YouniQ Machining’s requirements.

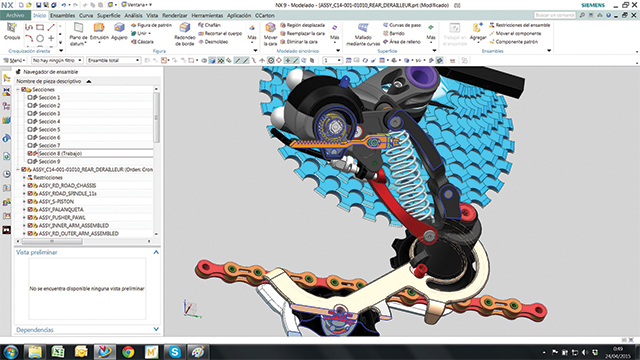

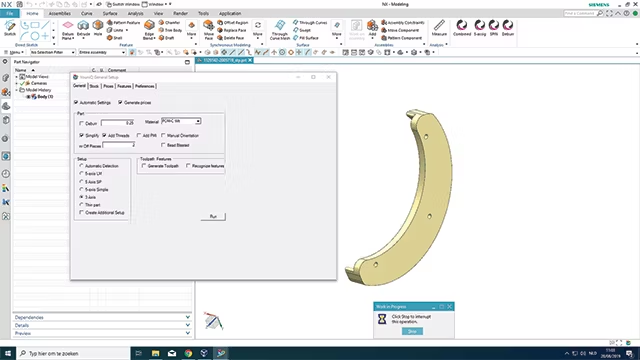

Through its NX™ product development software, Siemens offered best-in-class CAD/CAM integration and application programming capabilities that quickly exceeded those of other suppliers. Key features of NX that filled all gaps included web integration using the JT™ data format and the NX Open API for programming and customization. Together, these elements provided an open environment, excellent programming potential, and a strong CAD connection, which became increasingly important over time.

Realizing the vision through digitalization

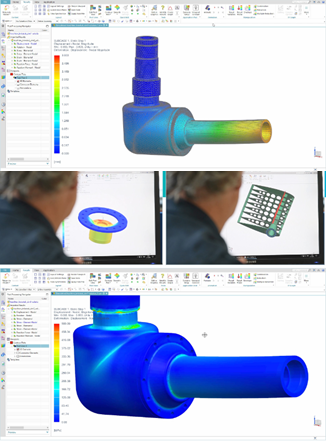

YouniQ used Siemens’ solution to redesign conventional processes through end-to-end digitalization. The result is a process that provides customers with transparent pricing, direct feedback on producibility, finishing options, and design modifications that reduce costs and lead times. Most importantly, the streamlined digital process reduced delivery times from eight to 12 weeks to as little as two days. Furthermore, the process does not require customers to submit extensive 2D technical drawings.

Synchronous modeling accelerates design modifications

A key capability of the NX solution that enabled this reimagined process is synchronous modeling, a technology that allows direct editing of component geometry regardless of the source CAD system. Synchronous modeling eliminated the need to manually modify the original CAD design; with NX, YouniQ can easily redesign parts to ensure all specifications and tolerances match the requirements.

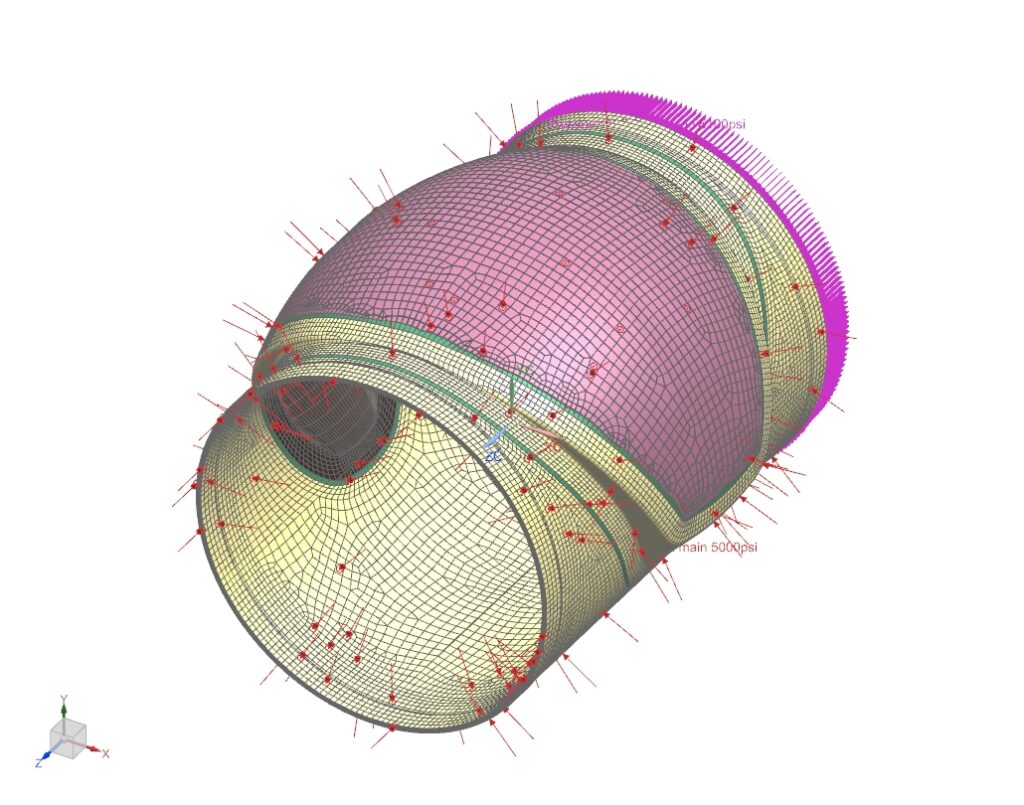

Automating NC programming with machining

The feature-based machining capabilities of NX CAM were also crucial to the digital workflow. With feature-based machining, numerical control (NC) programs can be automatically created based on the features in the component model. A tool called the machine knowledge editor (MKE) allowed YouniQ engineers to record all the rules and tools used in machining features, capturing knowledge and data that drive automated NC programming.

Results

With its web-based machine shop and automated, hands-off workflow, YouniQ Machining reduced time-to-market from the typical eight to 12 weeks to just two days for fast delivery. The company also offers additional delivery options that reduce costs: standard delivery in five business days and budget delivery in 15 business days.

With its fully digitalized workflow, YouniQ Machining achieved higher margins than competitors, allowing investment in future innovations. The company also reduced its reliance on highly skilled experts and minimized its administrative burden, enabling the business to focus on core machining operations. With processes defined and programmed in NX, the company standardized its development procedures and enabled hardware standardization in production.

While Siemens’ NX CAM solution was a key element in achieving these impressive results, the professional support and consultation of Emixa Industry Solutions also played a significant role. With in-depth knowledge of Siemens NX CAD/CAM, automation, and postprocessing, and extensive industry insights, this Siemens Platinum business partner translated YouniQ Machining’s business needs into concrete, practical solutions. Emixa Industry Solutions’ vast experience in providing high-end technical solutions for demanding environments enabled fast and seamless implementation, minimizing downtimes and disruptions. Additionally, Emixa Industry Solutions offers a continuous feedback loop to identify and resolve future challenges and developments.

Future plans

Looking ahead, YouniQ Machining plans to add more interactivity to its web platform, including the ability for customers to add tolerances without 2D drawings and to eliminate manual product approval through advanced algorithms. The company also aims to automate the processing of product and manufacturing information (PMI – 3D annotations in part models) to support model-based design and offer a wider variety of materials.

-640x360.jpg?w=900&fit=max&q=60&dpr=1&auto=format)

-640x360.jpg?w=900&fit=max&q=60&dpr=1&auto=format)

-640x360.jpg?w=900&fit=max&q=60&dpr=1&auto=format)

-640x360.jpg?w=900&fit=max&q=60&dpr=1&auto=format)

-640x360.jpg?w=900&fit=max&q=60&dpr=1&auto=format)

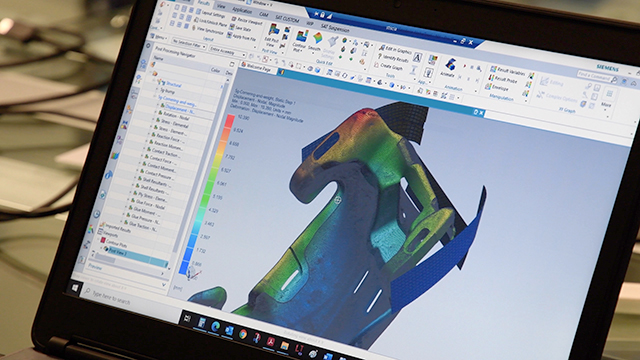

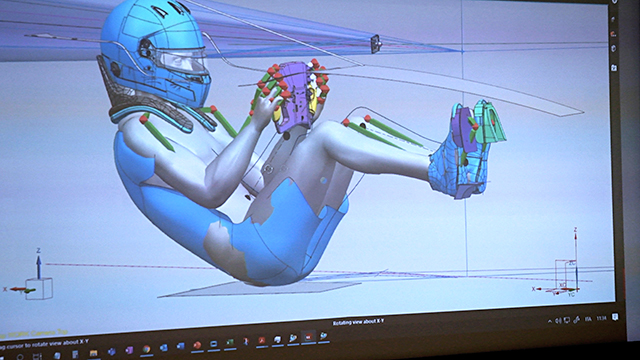

Zooming around over 300km/h during a normal F1 race, drivers experience up to four or five lateral G’s routinely under braking and cornering and during acceleration on the long stretches.

Zooming around over 300km/h during a normal F1 race, drivers experience up to four or five lateral G’s routinely under braking and cornering and during acceleration on the long stretches.

Data is king: any piece of information the team can analyze will help them understand the performance behavior of the new car.

Data is king: any piece of information the team can analyze will help them understand the performance behavior of the new car.