Product: TEAMCENTER

Industry: Aerospace and Defense

Using the Teamcenter solution for Reporting and Analytics, ATK pulls information from multiple enterprise systems, providing intelligent insight for smarter decisions.

Innovation delivered through PLM

ATK is a premier aerospace and defense company with approximately 17,000 employees working throughout the United States, Puerto Rico and internationally. The company develops and manufactures highly engineered materials and products that support mission-critical applications for its defense, aerospace, and security and sporting customers.

ATK’s business objective is “Innovation Delivered.” To fuel innovation, the company has fully embraced a product lifecycle management (PLM) strategy across its divisions and value chain. Siemens Digital Industries Software solutions – NX™ software, Tecnomatix® software and Teamcenter® software – form the foundation of ATK’s PLM strategy, which spans the product lifecycle. “Our use of PLM extends from portfolio management, to gathering requirements, and then using those requirements throughout all the organizations inside ATK, and even our supply chain outside of ATK, to deliver products that meet our customers’ needs,” explains Jon Jarrett, director of engineering processes and tools at ATK.

The information exists, but how to get at it?

ATK’s PLM database contains a wealth of product and process data, yet it is just one source of information that managers tap as they carry out their programs. Other relevant data resides in financial systems, the company’s enterprise resource planning (ERP) system, the company’s scheduling system, and so on. With critical business information segregated in “silos,” it had become difficult to answer common business questions such as, “What is my first-pass yield?” or “How many documents are needed to support this program and will they all go out on time?”

ATK had been answering such questions by assigning a person to comb through the relevant databases, contact the appropriate people, and prepare a report. Some of thosead hoc reports required as many as 80 hours to generate. And while the company was able to get answers to specific questions this way, managers were not able to use data easily or proactively. In fact, many had created their own spreadsheets and other documents for tracking programs and processes. “People were doing duplicate work and there was no consistent format for those documents,” says Jarrett. “And people were constantly being pinged for information. Those interruptions are very detrimental to productivity. We wanted more efficiency in getting the data out, and we wanted it displayed in a way that everyone could benefit from.”

A BI solution that works with PLM

A business intelligence (BI) solution – software designed to identify, extract and analyze data – seemed to be what ATK needed. The company’s first use of a BI solution for PLM data, however, was a failure. “We went down the path with a certain BI solution to pull PLM data, but it couldn’t understand PLM data models or security rules,” says Paul Nelson, PLM architect at ATK. “We didn’t want people to see data they shouldn’t have access to. We wanted to be able to mine that data for gold, but not make it a free-for-all.”

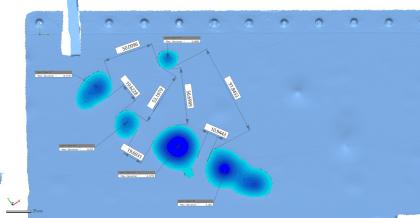

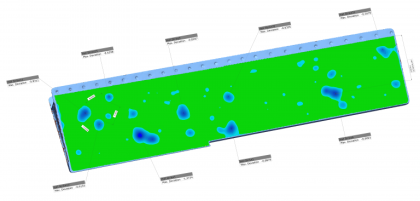

Next, ATK tried the Teamcenter solution for Reporting and Analytics, which turned out to be a much better solution. Not only is Reporting and Analytics able to work with the Teamcenter data models and security rules, companies can utilize it to extract information from multiple sources, including commercial applications like ATK’s financial systems as well as home-grown programs. In addition, with Reporting and Analytics, users can aggre-gate data from multiple sources into reports and dashboards. Users can explore varying degrees of lower-level data to understand project specifics or higher-level data to get the big picture. ATK’s reports and dashboards typically contain three categories of information – for executives, managers and individual workers.

“Using Reporting and Analytics, we can quickly pull out data that helps us run our business,” says Nelson. “We’re getting gold out of that data now. It’s unlocked, and it can be presented in a way that people understand immediately.” For example, ATK has established a Science and Engineering dashboard that is accessed through a SharePoint portal. “With just a glance, people can see that screen is red or green, and know the status immediately.”

Report writers reassigned; everyone is more efficient

A dashboard showing costs and schedules is displayed continuously on a big-screen TV in a well-traveled place where everyone can see it. In addition to dashboards, ATK has used Reporting and Analytics to develop a number of highly useful reports. This work is done by Tim Gleason, an ATK software engineer, who is now handling a volume of work that required four people previously. “Tim can barely keep up with all the requests for reports, which come from managers and occasionally even from customers,” says Jarrett. “But we used to have four people doing this work. Now it’s just Tim. The others have been reassigned.” Reporting and Analytics’ tools allow Gleason to create reports much faster than anyone could previously, and he appreciates the fact that he can easily arrange the information in any format anyone requests.

A great example of the kind of “gold” that ATK now easily mines from its business systems is one called the “Automated Requirements Volatility Metric (ARVM)” that draws from Teamcenter System Engineering data. “One of the predictive metrics established by the International Council on Systems Engineering (INCOSE) to determine program success is how often requirements change during the life of the program,” explains Nelson. “You’re not going to have a successful program if you’re trying to hit a moving target. The ARVM reports track how many of those baseline requirements are changing on a monthly basis. If they are changing more than a certain threshold, the screen turns red. It’s a way for a program manager to monitor the health of the program.” ATK did track this information in the past. In fact, they had assigned one person to gather data and provide the monthly report. That person has been reassigned.

Other reports used at ATK include one that lets people see all the items they have due within a certain timeframe. “Typically people just get the hammer when they’re behind. This shifts the focus from firefighting to being proactive,” says Nelson. Another report shows managers how many documents must still be completed for a given program. By combining information from the PLM system and the scheduling system, this report can also tell the manager exactly how many hours are needed to complete that work.

In general, the deployment of Reporting and Analytics has made everyone, from executives to engineers, more efficient, according to Jarrett. “People are not being bugged all the time, and they’re not having to do their own Excel reports,” he says. “We are saving thousands of hours this way.” Another advantage of the Teamcenter solution is that information is more current. With reports that formerly took up to 80 hours to create now avail-able automatically, many reports are generated on an hourly, daily or weekly basis rather than monthly. This real-time visibility helps drive data integrity and accuracy. Finally, ATK is seeing its executives take greater advantage of the information in the company’s enterprise systems. “Sure they could do an advanced search of a database, but they are too busy for that,” Nelson explains. “If you break down the barriers, as we have done by giving them a dashboard that’s very graphical and user-friendly, you get more leadership engagement with the data.”