Industry: Aviation

The importance of the Digital Thread for AERALIS

AERALIS is a digital enterprise that leverages digital engineering and a digital thread in accordance to AERSIDE: AERALIS Smart Integrated Digital Enterprise. As requirements and technology changes in the aerospace industry, it is absolutely needed to be a digital enterprise. Charlie says, “Aircraft are designed about 20 years before they land on the market in some cases, and by that point, the requirements and technology have completely changed. So, there’s a real push to keep up with that change and reduce the period from ideation to launch.”

Charlie defines digital engineering as “the application of digital processes throughout the entire lifecycle of a system, from concept to manufacture, operation, certification and disposal, but all connected via a single source of truth.” At AERALIS, the entire lifecycle of the aircraft is digitally developed, connected by a single source of truth. Callum says this digital engineering enables efficiency, collaboration and innovation.

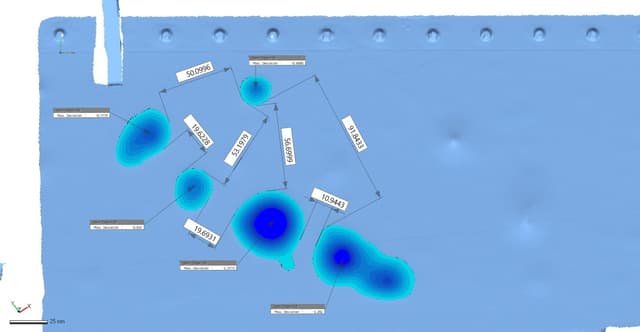

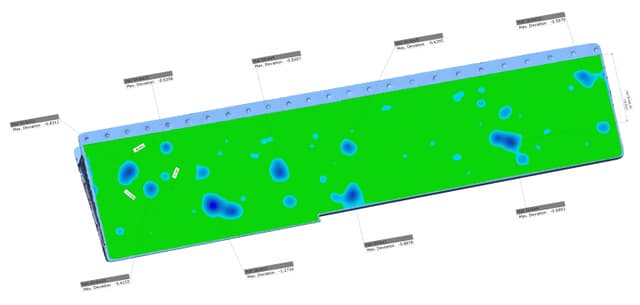

With a digital thread, they can design parts based on known requirements, and anyone can see and be notified of changes to requirements or parts themselves. Callum again emphasizes how a digital thread enables efficiency. With everything being digital-first, Charlie notes that AERALIS can easily collaborate in a live design environment with other designers or manufacturers. From simulation and optimization to manufacturing and real world operations, everything is linked together along the digital thread with digital twins.

Model-Based System Engineering (MBSE) at AERALIS

AERALIS adopts the Model-Based Systems Engineering Arcadia Method. Callum explains how they are “breaking down a problem at an operational level and then going into more detail at functional, logical and physical levels.” With this MBSE approach, they are not just using it on the aircraft but to all business operations as a whole. Charlie uses the comparison of just how computer-aided design (CAD) evolved and became a digital step in design as opposed to drawings on paper, MBSE is the development of digital models instead of just documents and drawings.

How AERALIS utilizes Siemens digital tools

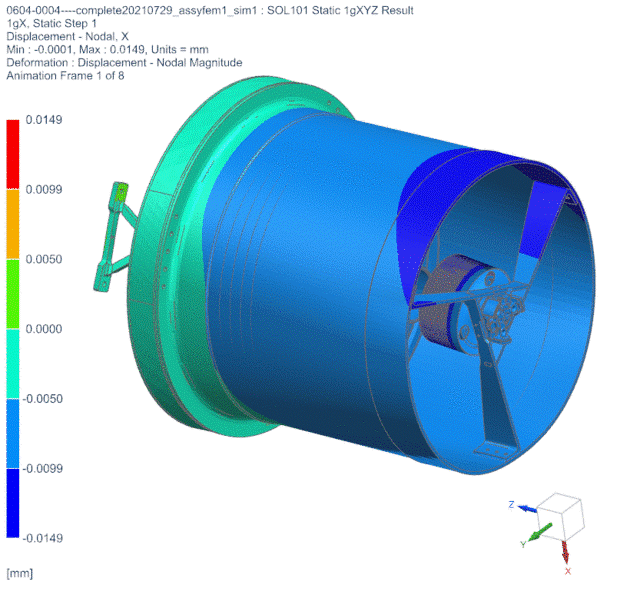

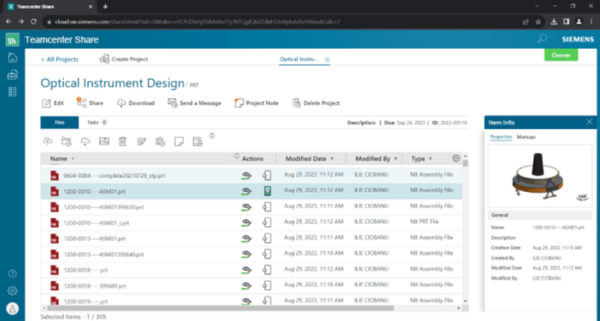

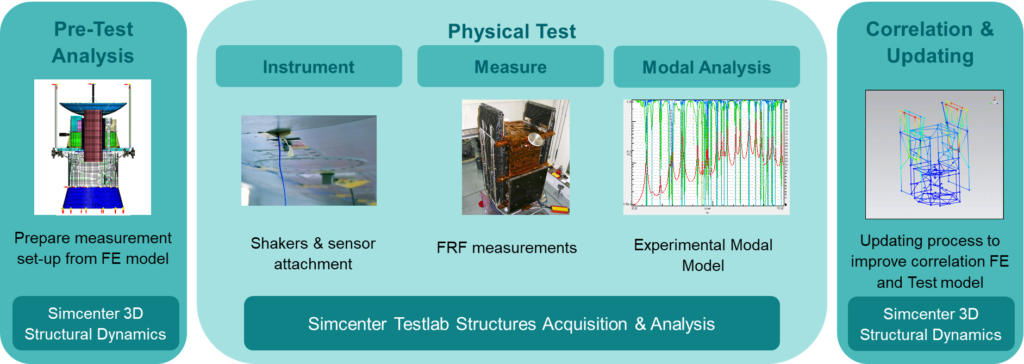

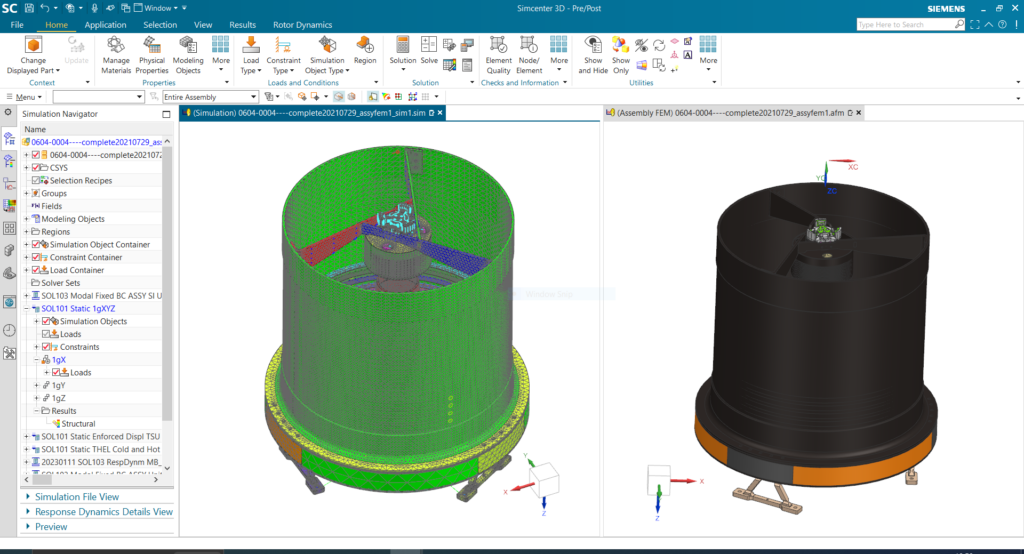

Charlie notes that at AERALIS, they are using tools from the Siemens Xcelerator software portfolio including NX CAD, Teamcenter, Teamcenter System Modeling Workbench, Simcenter (including Simcenter Test Lab and Physical Test Management System) and Polarion. They also may begin to use Opcenter when they get into manufacturing execution.

AERALIS works closely with Siemens with our professional services implementation team. AERALIS engages in agile collaborative feedback with Siemens daily, including identifying new capabilities that they need or trialing different capabilities and methodologies. “Every week, we’re designing something, building it, testing it, changing it a bit more, and working in that real agile sprint,” Charlie says regarding testing new capabilities they request. This workflow of close collaboration helps them launch, deploy and adopt new functionality amongst their engineers quickly.

How AERALIS uses NX to solve challenges

Callum notes that AERALIS has a managed NX environment, where everything in NX is integrated with Teamcenter PLM software to enable collaboration with design partners such as Hamble Aerostructures. With NX and Teamcenter, both design teams located in Bristol and Southampton can work together on the same live digital models with the same requirements. With NX and Teamcenter, they can leverage a full digital thread— “It is a thread and collaboration and efficiency and working on the same stuff. It’s not emails.”

Charlie and Callum also call out specific benefits they realize with NX, such as including maintainability in their aircraft from day one. NX also includes human models, so they can test their designs and make sure anyone from the largest man to the shortest woman can access all parts of the aircraft needed to fly. “You can mock the view of a pilot from their eyes, and you can move their head up and down, and you’ll be able to see what they see in the cockpit. So, you can map out the anthropometrics,” Charlie says.

The design process at AERALIS

Callum briefly explains the design process at AERALIS, stating that it operates as a “thin prime.” They are modular in their organization and design by a requirements-driven approach. They collaborate with Hamble Aerostructures for some of the design and manufacturing including the Common Core fuselage, and other design firms for system design. With multiple companies, they still design as “one team” as a digital enterprise.

Aerospace industry challenges

Charlie and Callum then describe some of the challenges being seen in the aerospace industry and how AERALIS is responding to them. Charlie notes that aircraft systems have more complexity, take longer to develop, need more resources and require a bigger industrial base. Requirements change quickly, and pilots need to train based on those new requirements, but the trainer platforms have to adjust and adapt. He also notes that traditional companies wrestle with legacy IT estates that are not on new technology and not digital. He acknowledges that while AERALIS does not have a legacy IT estate to deal with which allows them to innovate faster, that it also means they are building an organization, processes and toolsets at the same time as trying to build the aircraft itself.

Callum adds on to the challenge of increasing complexity, saying that certification is getting more expensive as complexity and requirements evolve. “I fear that may be reducing the appetite for people to try new things, and limiting how eVTOLs are progressing,” he states.

Greg asks if there are any challenges that are unique to AERALIS, and Charlie mentions that there are not many new aerospace companies in general, but it is especially a challenge as they are trying to do something that has not been done before in the defense industry: modular aircraft. They have to balance the need to get it to market, getting it flying and getting it certified. But they are leveraging partnerships and collaborations with other companies across the UK and the world to solve these challenges.

When it comes to overcoming challenges, Callum says that at AERALIS they start from a theoretical standpoint and ensure that they are future-proofing and having one single source of truth for solutions as they communicate and share data. He shares an example of a challenge they had with part numbering, but states that their “secret sauce” is simply: “Just think about it as a whole— don’t just jump in— and try to build something for the future.”

The future of design at AERALIS

Before closing out the episode, Greg asks about some trends in the industry. They discuss sustainability, noting that sustainability will only increase and leveraging digital tools will allow them to identify more opportunities for optimized and sustainable solutions. The modularity of an AERALIS aircraft is inherently more efficient and sustainable as it is adaptable.

They also address the Industrial Metaverse and Immersive Engineering and look forward to experiencing the benefits of Immersive tools from initial requirements to design to manufacturing. “You can sit on a chair, put a VR headset on, and play around with potential cockpit designs. That’s only possible because we’ve been designing digitally from day one,” Charlie says.

We conclude the episode talking about AERALIS’ ultimate goal of revolutionizing the aerospace industry with modular defense aircraft, how they think the aerospace industry has evolved in their few years as engineers and how it will continue to evolve and their perspective on the general next generation of design.

-640x360.jpg?w=900&fit=max&q=60&dpr=1&auto=format)

-640x360.jpg?w=900&fit=max&q=60&dpr=1&auto=format)

-640x360.jpg?w=900&fit=max&q=60&dpr=1&auto=format)

-640x360.jpg?w=900&fit=max&q=60&dpr=1&auto=format)

-640x360.jpg?w=900&fit=max&q=60&dpr=1&auto=format)

-640x360.jpg?w=900&fit=max&q=60&dpr=1&auto=format)

-640x360.jpg?w=900&fit=max&q=60&dpr=1&auto=format)