Industry: Industrial machinery

Ensuring Consistent and Reliable Quality

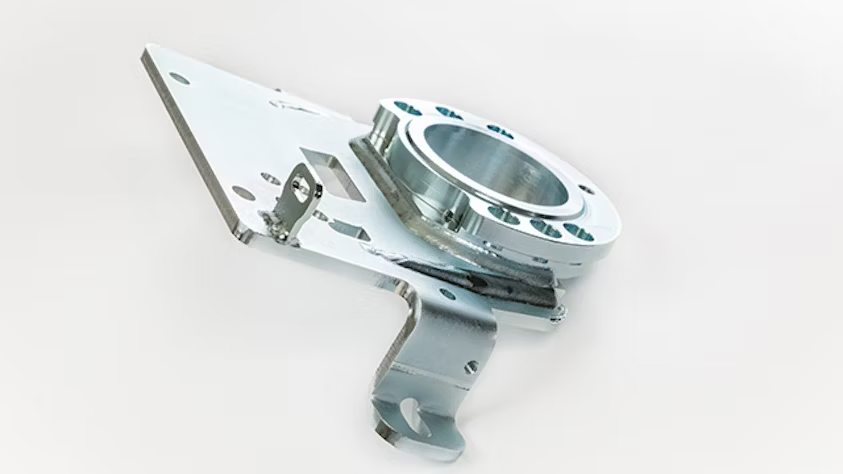

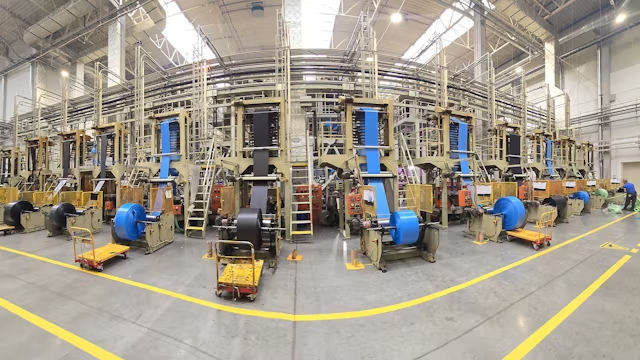

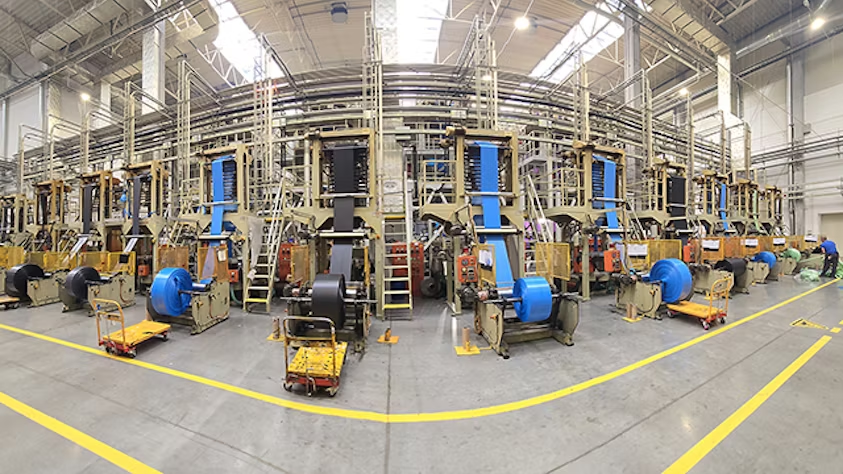

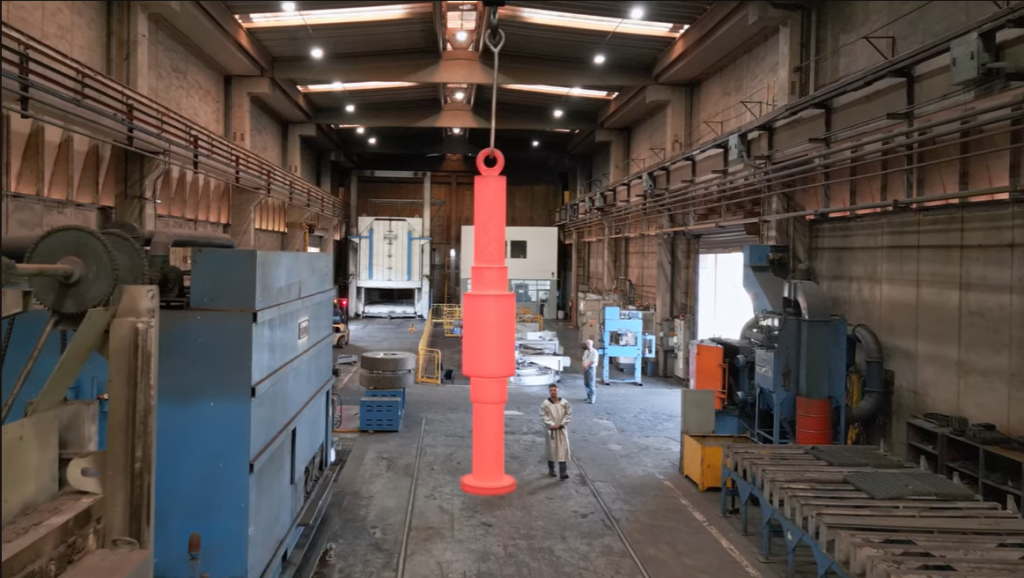

Metal Design specializes in the development, optimization, and production of technologically demanding metal products and machine components. As an international partner for various Western European companies, it has built a reputation for delivering consistent and reliable quality.

With over 30 years of experience manufacturing metal parts—including welded assemblies, sheet metal products, and machined components—Metal Design aims to become a recognized European leader in producing complex metal components for advanced industries such as green technologies, agricultural machinery, automated internal logistics vehicles, and medical applications.

As the company expanded its production capabilities and invested in new technologies, operational planning became increasingly complex. Manufacturing processes require a precisely timed sequence based on the bill of materials (BOM), ensuring optimal machine utilization, efficient workforce deployment, and strict adherence to customer delivery deadlines. As Metal Design focused more on highly technical products with multi-layered BOMs and intricate production methods, managing these challenges manually became unsustainable.

To address these issues, Metal Design partnered with INEA d.o.o. (Inea), a Siemens Digital Industries Software partner, and adopted Opcenter™ advanced planning and scheduling (APS) software—part of the Siemens Xcelerator portfolio of software, hardware, and services.

Overcoming Inefficiencies Through Digital Transformation

At the start of its digital transformation journey, Metal Design relied on a basic enterprise resource planning (ERP) system from a local IT vendor and a free version of production planning software. The company later developed in-house applications to assist with planning and scheduling, as well as tasks like item sorting, BOM verification, and tracking production times.

However, this hybrid approach was inefficient. The production manager manually adjusted monthly and weekly schedules using a combination of in-house tools and personal expertise. As a result, scheduling relied heavily on intuition and complex, manually managed tools. The IT administrator struggled to optimize production planning, and the company was not leveraging software effectively.

Recognizing these inefficiencies, Metal Design made a decisive move: replacing its ERP system and upgrading its production scheduling software simultaneously.

Selecting Opcenter to Optimize Scheduling

The production manager tested three APS software solutions in demo versions using real production data. Opcenter Scheduling stood out due to its user-friendly interface, scalability, and ability to solve scheduling challenges. Additionally, the production manager had prior experience with Opcenter from his mechanical engineering studies, underscoring the value of Siemens’ collaboration with academia.

A key moment in the decision-making process came when Metal Design received an urgent customer order that initially seemed impossible to fulfill on time. Using Opcenter Scheduling, the company simulated production scenarios, accounted for existing orders and shop floor constraints, and determined that completing the order was feasible. This capability convinced the production manager that Opcenter was the right solution.

Implementing Opcenter Scheduling

The implementation process began with a thorough analysis of all production processes, requirements, and parameters. This review allowed Metal Design to refine its data and enhance accuracy.

Once integrated, Opcenter Scheduling provided insights across multiple departments—including technology, procurement, sales, and production—helping teams resolve daily challenges more efficiently.

“Opcenter Scheduling was the best fit because it’s the most optimal for our needs and company size, providing all the necessary functionalities at an affordable price,” says Jerneja Curk, Assistant General Manager at Metal Design. “With Opcenter and the support of Inea, we have elevated our production scheduling to a higher level.”

By fine-tuning scheduling parameters, adjusting capacity settings, and fully understanding the software’s capabilities, Metal Design significantly improved its production planning standards. A crucial step was integrating the new ERP system with Opcenter Scheduling via web services, enhancing the accuracy of scheduling operations and feeding scheduled data into the company’s business intelligence (BI) system.

“In our old system, it took up to two hours to prepare and import data. With Opcenter’s ERP integration, we now just press a button and wait a few minutes,” says Karin Kodele, Production Coordinator at Metal Design.

By optimizing machine changeover times and resource allocation, Metal Design achieved record monthly production levels—tripling its usual output without increasing resources.

Enhancing Efficiency and Customer Confidence

Metal Design frequently needs to simulate potential customer orders before creating work orders in its ERP system. This process previously took up to four hours per inquiry, but with Opcenter Scheduling’s order inquiry functionality, it now takes just 15 minutes.

“Using Opcenter Scheduling, I can efficiently schedule the entire shop floor and all shifts while quickly responding to customer inquiries,” says Kodele. “Working with Inea, their support is exceptional, and their quick, efficient responses always impress me.”

“With over 700 different parts in production and long-term B2B partnerships, delivering on time is crucial to our clients’ supply chains,” says Polona Curk, Director of Business Development at Metal Design. “Our B2B customers are always impressed when they learn we use Siemens’ Opcenter Scheduling. It reassures them that we will deliver as agreed, which strengthens our business relationships.”

Looking Ahead: Future Optimizations

Following the successful implementation of Opcenter Scheduling, Metal Design’s future plans include further optimizations, such as integrating employee skill matrices into scheduling. Additionally, the company aims to transition from general schedule overviews to personalized displays for each production cell on the shop floor.

By leveraging Opcenter Scheduling, Metal Design has embraced digital transformation, streamlined production planning, and positioned itself for continued growth in the competitive metal manufacturing industry.

-640x360.jpg?w=900&fit=max&q=60&dpr=1&auto=format)

-640x360.jpg?w=900&fit=max&q=60&dpr=1&auto=format)

-640x360.jpg?w=900&fit=max&q=60&dpr=1&auto=format)

-640x360.jpg?w=900&fit=max&q=60&dpr=1&auto=format)

-640x360.jpg?w=900&fit=max&q=60&dpr=1&auto=format)

-640x360.jpg?w=900&fit=max&q=60&dpr=1&auto=format)

-640x360.jpg?w=900&fit=max&q=60&dpr=1&auto=format)

-640x360.jpg?w=900&fit=max&q=60&dpr=1&auto=format)

-640x360.jpg?w=900&fit=max&q=60&dpr=1&auto=format)

-640x360.jpg?w=900&fit=max&q=60&dpr=1&auto=format)

-640x360.jpg?w=900&fit=max&q=60&dpr=1&auto=format)

-640x360.jpg?w=900&fit=max&q=60&dpr=1&auto=format)

-640x360.jpg?w=900&fit=max&q=60&dpr=1&auto=format)

-640x360.jpg?w=900&fit=max&q=60&dpr=1&auto=format)

-640x360.jpg?w=900&fit=max&q=60&dpr=1&auto=format)

-640x360.jpg?w=900&fit=max&q=60&dpr=1&auto=format)