Product: HandySCAN

Industry: Aerospace and Defense

EADS (European Aeronautic Defense and Space company) is a worldwide leader in aerospace, defense, and associated services. The company has been using Creaform portable 3D measurement products for several years.

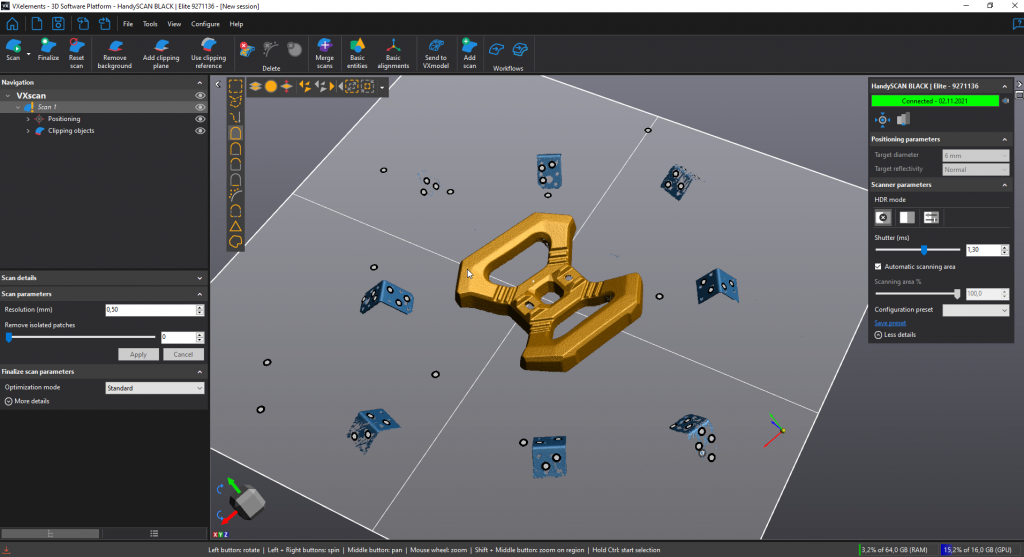

More specifically, EADS uses both the HandySCAN 3D and the MetraSCAN 3D optical CMM scanner for scanning tooling and composite parts (carbon/epoxy) and for making parts/CAD comparisons. For its probing needs, EADS uses the HandyPROBE optical CMM. In addition to using VXelements, the data acquisition software behind all Creaform systems, EADS additionally uses the VXtrack module for dynamic measurements, as well as VXlocate, a software module developed through a partnership between Creaform and EADS.

HandySCAN 3D Application Example

As part of a study on the possible geometric distortion of carbon fiber composite parts and with the help of a HandySCAN 3D device, EADS scanned a 1 000 mm x 800 mm tooling equipment, as well as 650 mm x 300 mm parts, to assess post-manufacturing deformation.

Parts on tooling

First, EADS scanned the tooling, in order to verify its compliance with the CAD plan.

Scanning the tooling with the HandySCAN 3D

Then, two parts manufactured with this tooling were scanned, and the scanning files were compared.

Scanning the parts and results

Results: tooling/parts gap

The second step consists of using very powerful simulation tools to estimate the distortion of the parts before manufacturing, in order to compare the manufacturing parts scanning files.

Simulation

The results EADS obtained made it possible to validate the simulation software, which was developed to optimize the manufacturing range by identifying adequate parameters and processes.

This project could have been completed with a fringe projection scanning system, but the one EADS owns cannot be used for such large surfaces, and the process is a lot more complex when it comes to measuring the two faces of the composite parts. Additionally, a CMM could have been used, but this possibility came with two drawbacks: one-off measurements, which in turn lead to a much longer acquisition time.

“ The Creaform system enabled us to quickly scan the metallic tooling and the carbon fiber composite parts. Many other systems that are available on the market do not work very well on these composite parts, which aspect is very dark and sometimes very glossy. The equipment being so portable made it possible for us to record the measurements right at the manufacturing site,” explained Ms. Catherine Bosquet, from the EADS Structure Health Engineering (NDT & SHM) department.

“ Before using Creaform’s systems, we used fringe projection, since we purchased a HOLO3 system over 15 years ago. We also tested other available systems (Konica Minolta, Metris, Steinbichler, Aicon, Kreon Technologies, Ettemeyer, GOM), but the Creaform 3D measurement solutions convinced us, because of their quick set up and acquisition, ease of use, measurement performance for many types of surface states, as well as their portability.We must also mention that Creaform experts are always highly available and responsive.”