Electronics and Semiconductors

Automating and standardizing PCB engineering planning

Industry: Electronic

Standardize and unify manufacturing operations

Connect Group NV (Connect Group) is a multinational electronics manufacturing services (EMS) contractor, providing printed circuit board (PCB) assembly and cable assembly services for various customers in the automotive, railway, healthcare, infrastructure, defense and avionics industries. The company is headquartered in Kampenhout, Belgium, and maintain production facilities in Belgium, the Netherlands, Germany, Romania and the Czech Republic.

Connect Group was established in 1987 and, in recent years, has acquired a series of European electronics manufacturers including IKOR, a company with locations in Spain, China and Mexico. Wouter Peene, operations manager for Connect Group, was faced with coordinating the activities of its new subsidiaries and reorganizing company-wide work practices.

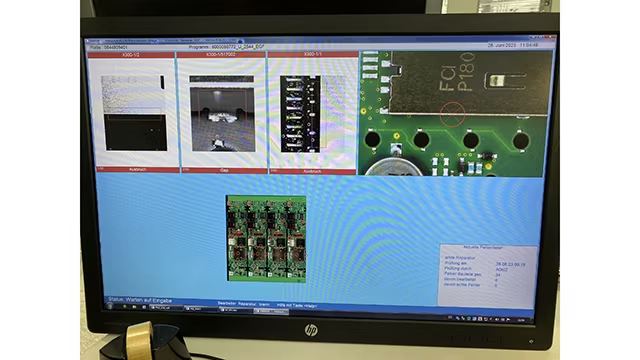

“My goal was to standardize and unify manufacturing operations in all of our sites,” says Peene. “This wasn’t an easy task. We had machines from different vendors at each site. All of our engineering and testing departments were using different software and methodologies, including legacy solutions such as UNICAM 6.2 and Test-Expert 7.3. In addition, we used a lot of manual processes, such as offline board inspection, to discover incorrect component positioning and rotation.

“At first, we wanted to keep using some of our existing legacy software to leverage our knowledge and save time and money. But none of our existing solutions could support our entire operation. They lacked interfaces to many of our machines and couldn’t generate the documentation we needed.

“We needed an end-to-end solution that would serve all our production sites,” says Peene.

The Valor solution

Since Connect Group was already using Valor™ Process Preparation software in some of its factories, the company decided to expand its use of the software to access more of its engineering capabilities. Valor Process Preparation is part of the Siemens Xcelerator portfolio, the comprehensive and integrated portfolio of software, hardware and services.

“We were already using the vPlan function in Valor Process Preparation and realized we could benefit from additional functions,” says Peene. “For example, we used the Valor Process Preparation automated stencil tool across the organization. Getting the stencil right requires special expertise that wasn’t always available. Using the stencil tool helped us reduce soldering errors and the lead time required by the stencil-cutter service provider.

“Currently, we use the virtual sticky tape feature to verify component position and polarity before starting production. The comprehensive digital twin approach enables us to shorten the verification process and reduce downtime. Using Valor Process Preparation allows us to connect to all of our machines so we can implement it as a company-wide solution.”

Connect Group used Valor Process Preparation and the comprehensive Valor Parts Library software component database to accurately simulate each component’s shape. “Using Valor Parts Library helps us eliminate costly design errors before production starts,” says Peene.

In addition, Connect Group used Valor NPI software, Siemens’ on-premise design-for-manufacturing (DFM) platform. “We offer the Valor NPI DFM as a service to our customers,” says Bart Allaert, head of the company’s technology is a service group, “It is part of the shift left concept, encouraging the designer to be aware of manufacturing constraints.

“They use DFM to ensure their design is manufacturable, so we spend less time afterward tweaking the design for them. Then, we use Valor NPI to perform checks and generate an analysis of the PCB assembly and tests. Using Valor NPI helps us bring higher quality products to market, faster, as part of a First Time Right strategy” says Allaert.

Return-on-investment

Connect Group established an execution team with Siemens that provided training sessions to implement a solution for all production locations in a few months. The centralized solution enabled Connect Group to easily move production between sites whenever necessary.

Following implementation of the Siemens solution, Connect Group reported a return-on-investment (ROI) within six months based on increased company profits of approximately €400,000 per year thanks to improved manpower and reduced downtime on its production lines.

Connect Group has major profitability factors, including product engineering, flying probe testing (FBT) and project migration.

The product engineering solution helped engineers reduce manpower requirements by about two hours per project, multiplied by 2,500 projects per year, for a total of 5,000 hours.

Using Valor Process Preparation saved Connect Group engineers approximately two hours of FPT programming per project multiplied by 500 projects per year, for a total of 1,000 hours.

When transferring a project to a different site, the process took an average of eight hours. Using Valor Process Preparation, the task is now completed within minutes. Connect Group migrates an average of 75 projects per year, resulting in a savings of 600 hours.

As a result, Connect Group has reduced manpower requirements by 6,600 hours per year. In addition, each of the above factors contributed to a reduction in line downtime. These improvements helped the company improve profitability by €400,000 per year.

Additional features for the future

“To optimize our use of the Siemens solution, we’ve made requests for additional features that are scheduled for upcoming releases. Siemens fully understands our requirements and supports us in adapting the software to our needs,” says Peene.

Profiting from interconnected, automatic data collection and detailed workflow documentation during PCB manufacturing

Industry: Medical

When we do have to make a tricky decision because of a supply chain issue or other unexpected event, using Opcenter lets us simulate and compare different scenarios.

Florian Funke, Production Scheduler

Siemens Healthineers

Exacting medical equipment industry demands

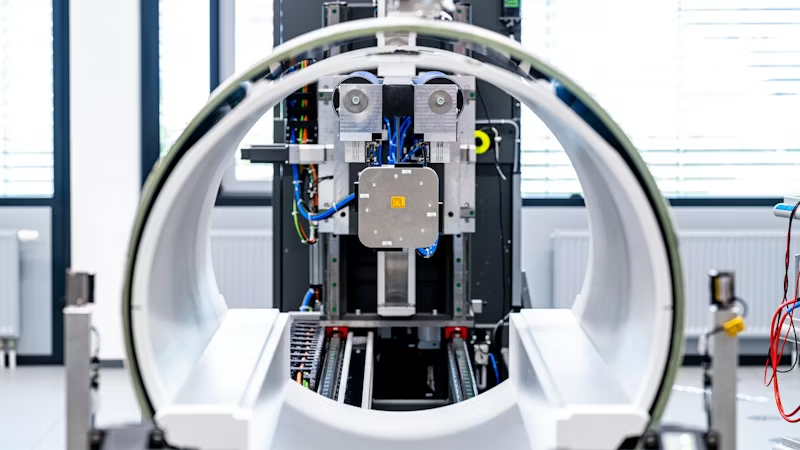

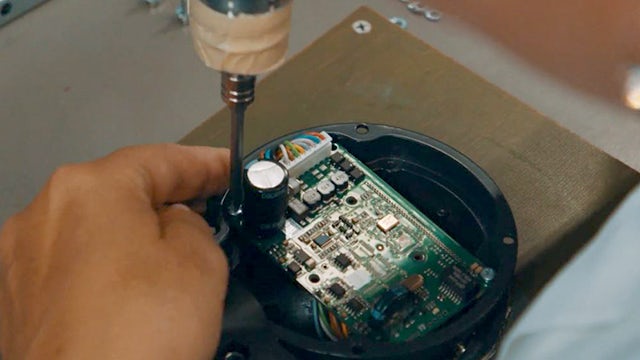

Manufacturing printed circuit boards (PCBs) requires precision, perfect duplication, high speeds, expert raw and rare material management and flexibility. This includes using robots and specialized, high tech equipment to work holistically on dedicated batches in changeable production lines. The entire process demands exacting accuracy, experts and fine-tuned processes without forgetting about sourcing and delivering those expensive raw materials and high tech components.

Now apply this to the highly regulated and exacting medical equipment industry. If you think there is a lot of complexity in the PCBs that run your smart phone or laptop, just imagine the scrutiny required for medical PCBs running a computed tomography (CT) scanner, ultrasound machine, photon scanner or magnetic resonance imaging (MRI) machine.

To ensure safe and reliable patient care, onboard medical PCBs must meet a plethora of strict standards and regulations, including Food and Drug Administration (FDA) and European Conformity (CE) approval. In addition to lists of health and safety factors (thermal management restraints and electromagnetic interference (EMI) issues), regulations also include standards for how a manufacturer designs and builds the medical PCB itself.

“We produce thousands of medical PCBs and components for all types of Siemens Healthineers equipment,” says Jochen Raaber, production scheduler at Siemens Healthineers, which is headquartered in Erlangen, Germany. “Every PCB needs to meet exacting quality standards. As PCB production planners, our job is to make sure that we have the right materials at the right location on time. These are the challenges we have nowadays.”

To overcome these challenges, the PCB production planners at Siemens Healthineers leveraged Opcenter™ Scheduling Surface Mount Technology (SMT) software, which is part of the Siemens Xcelerator business platform of software, hardware and services.

Turning complexity into a competitive advantage

The planning team at Siemens Healthineers needs to handle various products and customer requirements with varying degrees of PCB complexity according to the final medical equipment specifications. With a continually changing scheduling environment, just-in-time (JIT) delivery, production delivery deadlines and raw material and component shortages, it is crucial to create an advantage from changes in complex processes.

“We found that to succeed, we needed to be more process-based than product-based,” explains Florian Funke, production scheduler at Siemens Healthineers. “It is one of the key reasons we turned to the Opcenter team and its dedicated solution for SMT scheduling and planning.”

A core part of medical PCB manufacturing is SMT, which is an assembly technique where components are attached and connected to the PCB’s surface using batch soldering processes. The connections between the planner and the shop floor need to work well to achieve this outcome.

Previously, the planning team used a highly customized spreadsheet for assembly to shop floor planning. As experts, they found they could make the right calls based on experience. However, they knew they could improve by leveraging a better tool. One tool they tested using was the Opcenter Scheduling SMT software.

“What we liked about using Opcenter Scheduling SMT is that it covers all our job’s basics, like the production schedules, the frequency, the real-time changes when it comes to new products or short runs and the documentation capabilities, which are important in the medical equipment industry,” says Funke. “But where we really saw value were improvements in our big picture work order workflow. Now this was very interesting for us.”

Integrating SAP and ASM

Siemens Healthineers used Opcenter Scheduling SMT to tailor new features for automatically pulling data from three important workflow sources. This includes: 1) machinery, line configurations and resource availability from the shop floor; 2) work orders, schedules and work hours from an enterprise resource planning (ERP) system (in this case, SAP) and 3) material availability and location from the supply chain systems.

The team recently completed an SAP integration to publish XML work order data directly for PCB manufacturing. Using Opcenter Scheduling SMT automatically picks up files and processes the work orders with minimal effort from the planning team. After this success, the team was curious to see how Opcenter could be leveraged to handle a new process work-flow for a new product.

“When it comes to introducing PCBs for new products, we don’t need to do much,” says Funke. “With Opcenter, you don’t need to hunt down data from other sources, which used to take hours or even days if something was lost or not interconnected. Using Opcenter Scheduling SMT, everything is interconnected. We just select similar products, parts and component data directly from our ASM software. Leveraging Opcenter automatically picks up all the required data from SAP and the ASM. It loads all the lists in about a minute. This is an extremely quick way to get the missing product data for a new product.”

“Because all our data is aggregated in a single place within our Opcenter process, we don’t waste time fetching it from various sources,” says Raaber. “The data we use now is purpose-built for us and in one single place, which is optimal for our scheduling team.”

Increasing flexibility

Planners at Siemens Healthineers were also happy to learn they could use Opcenter Scheduling SMT to automatically assign work orders to individual lines with its factory schedule optimizer, Multiline, including aligning the work orders by grouping and sequencing.

“Compared to other solutions, using Opcenter Scheduling SMT is far more flexible,” says Raaber. “You can customize it exactly as you need it for the most complex production scheduling.”

The team can even tailor optimization criteria to its exact SMT and production line needs. This covers vital scheduling criteria, like production time, group count, due dates, missing parts, etc.

“We work with fixed groups and setups,” says Funke. “The tool does a lot of the work for us. Using it puts everything automatically in the correct setup and quickly assigns everything to the correct line according to the work order or product. We just check it. There is very little manual retrieval these days. We can comfortably work with a team of two on a shift, whereas in the past we needed three people on the floor to get the job done right.”

Improving downtime

The goal is to optimize the overall production process because downtime can hinder the most organized teams. Siemens Healthineers planners hoped to use Opcenter to reduce downtime and optimize production batches. As the recent global chip shortage and supply chain issues demonstrated, the more they can analyze and compensate for unexpected events, like a shipment stuck in transit or a shortage of standard chips or copper, the easier it is for Siemens Healthineers to meet on-time delivery commitments within their production environments.

“When we do have to make a tricky decision because of a supply chain issue or other unexpected event, using Opcenter lets us simulate and compare different scenarios,” says Funke. “We can even input our expertise and preferences by adding weight to the various criteria. Then we just choose the options and schedule that work best for overall production.”

“The software adapts to what is coming in the production process and leaves us with the flexibility to make the right informed choices,” says Raaber. “I think this is the key strength of leveraging Opcenter Scheduling SMT.”

The team at the Erlangen plant was up and running with ease after three days of installation support and hands-on training. They can use Opcenter Scheduling SMT to do the busy work, from importing orders from SAP and other sources to optimizing the SMT groupings for best-case changeover to flagging PCB production issues, including material availability. Additionally, leveraging the Opcenter Scheduling SMT what-if analysis capability is handy in a constantly changing world where Siemens Healthineers’ high tech production expectations require accurate, practical, on-the-fly scheduling expertise.

Hyundai Motor Group uses AI to reduce the parameter optimization process from 1 week to 15 minutes

Industry: Automotive

AI-powered shift left

In the vehicle development process, it is advantageous for companies to shift left in the V-cycle as much as possible. By avoiding late-stage design changes, engineering teams can achieve significant time and cost savings and help drive products to market faster.

Artificial intelligence (AI) is an increasingly popular tool to enable engineering teams to shift left. For example, engineers can train neural networks to search through enormous amounts of simulation models and data and help identify the ideal vehicle or component configuration.

Powered by AI, the effort to shift left is more urgent than ever as the world transitions to a more sustainable future with electrification. Many original equipment manufacturers (OEMs) are in the process of transitioning from producing internal combustion engines (ICEs) to battery-powered vehicles. Each of these vehicles has years of development data and simulation models that now need to be adapted for electrification.

Neural networks for vehicle target setting

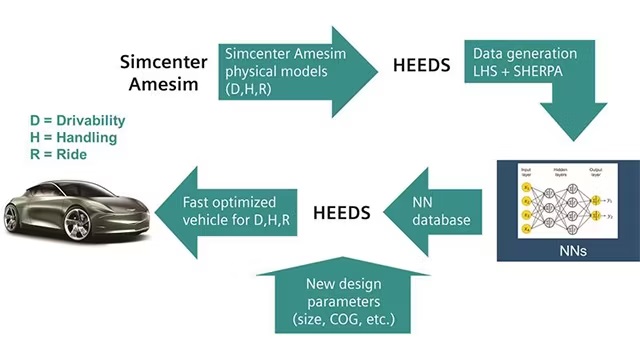

At the start of their electrification journey, Hyundai Motor Group (HMG) recognized the need to implement AI to enable a seamless shift left in the electric vehicle development process. In 2023, they partnered with Simcenter Engineering and Consulting services to build the neural networks that will enable them to define architecture-driven requirements at the concept stage of vehicle development.

Early in the design process (at the left of the V-cycle), engineering teams typically have an estimate of what they would like to see from their next generation of vehicle, including mass, size, suspension technology, etc. These early ideas need to be explored and analyzed in the most efficient way possible to define the ideal design and configuration. Target setting for attributes such as optimal mass, kinematics, drivability, ride and handling gives engineering teams subjective key performance indicators (KPIs) to meet. The earlier these targets can be met, the more time and cost savings a company can reap.

Ilsoo Jeong, comfort engineer, is part of the driving comfort virtual development team at Hyundai Motor Group. His team was tasked with target setting for chassis development of the Genesis GV 80, which will be released in a future generation as an electric vehicle (EV).

“Our goal was to achieve the best possible comfort and handling performance, so we had to consider hundreds of chassis parameters, such as mass distribution, suspension kinematics, the mounting system,” says Jeong. “We also needed to consider how these designs and configurations would need to be changed considering the ICE will be replaced with a battery.

“Additionally, we wanted the ability to perform sensitivity analyses to quickly understand how changes to the design of one component may impact the performance of others. We realized that taking advantage of AI could help us accomplish this quickly and efficiently. We partnered with Simcenter Engineering and Consulting Services to build these neural networks because they had the most expertise in Simcenter Amesim, our preferred tool, and because of their vast expertise in the vehicle development process.”

EV architecture optimization

In a separate project, the Simcenter Engineering Services team had collaborated with HMG engineers to develop an architecture in Simcenter Amesim software that could be used to evaluate a variety of vehicle maneuvers and provide automatic postprocessing.

This architecture allowed criteria to be weighed separately – including 52 individual KPIs for each requirement – to achieve an overall score, and it could handle over 350 parameters as input.

In this project, Simcenter Engineering Services expanded on this work to apply it to the chassis. Using the targets provided by HMG, Simcenter engineers generated over 200,000 simulation models in Simcenter Amesim and validated them against real vehicles. They saved the simulation results in a high-performance computing (HPC) to make them run faster in the future.

“Simcenter Amesim was the driving force behind our decision to select Siemens for this project,” explains Jeong. “Only Simcenter Amesim had the capabilities to perform the number of simulations we needed, as well as the flexibility for attributes such as NVH frequency. Simcenter Amesim was also advantageous because it enabled us to work with our own templates rather than a prepackaged one. When it came to flexibility and simulation time, Simcenter Amesim was the best choice.”

Using Simcenter Reduced Order Modeling software, Simcenter Engineering Services created and trained a neural network to deliver simulation results that enables direct optimization of models later in the process. This neural network integrates with HEEDS software to assist HMG engineers in identifying the ideal vehicle configuration.

“If our targets or parameters change, we will no longer need to start the entire process from scratch,” says Jeong. “We can now find the optimal parameter set very quickly by searching through the neural network built by Simcenter Engineering Services. The ability to easily retrieve these simulation results means we can give very quick feedback to each subsystem team on the ideal configuration. Later in development, we will also be able to efficiently compare the vehicle’s driving performance to our targets by using the benchmarking data retrieved by the neural network.”

AI-enabled time savings

The collaboration with Simcenter Engineering Services and use of Simcenter software has led to significant engineering process benefits for Jeong’s team.

“Before this project, one requirement evaluation took two minutes to run in simulation,” says Jeong. “Using the neural network developed by Simcenter Engineering Services, this was reduced to one-tenth of a second. Similarly, our subsystem parameter optimization process used to take a week. With the help of Simcenter Engineering Services, this has been reduced to 15 minutes.”

Together, Jeong and the Simcenter Engineering Services team are working to reap even more efficiency benefits from this neural network. They will soon integrate with Teamcenter software to fully link to and provide traceability for parameters and requirements. This will enable a program manager with no knowledge of simulation to directly input their requirements and use parameters from a previous project to run simulations directly on the web. They can then predict system performance or optimize parameter sets for subsystems, bringing the power of system simulation to nonexperts.

“Siemens’ Simcenter portfolio and Simcenter Engineering Services will continue to be a special development partner for HMG,” says Jeong. “Our companies have a strong relationship and I look forward to collaborating on future projects.”

Using AOI false call reduction software increases first pass yield by 42 percent

Industry: Electronics

Opcenter Intelligence fits perfectly with our needs. We are always looking for innovative technical solutions and using Opcenter AOI FCR enabled significant improvement with reduced effort, which customers benefited from as well.

Tobias Morlock, Head of Process and Technology (Manufacturing)

Siemens Rastatt

Reducing false positives

Siemens Rastatt, which is part of Siemens AG, develops, manufactures and markets products and systems for heating, ventilation and air conditioning (HVAC) technology in Rastatt, Germany. Their products are used in a variety of applications, including forced-air burners, boilers, alternative heating systems and industrial plants. Siemens Rastatt provides complete system solutions as well as controls, actuators, valves, automatic burner control systems for oil and gas burners and associated test equipment.

Their components are found in residential boilers and larger systems, such as in airports. They are also used in industry; for example, in drying equipment in paint lines of major car manufacturers.

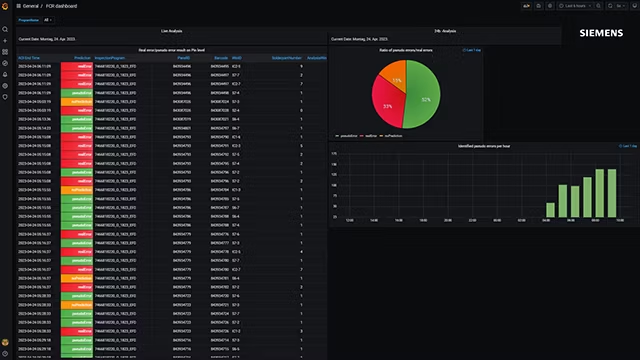

Siemens Rastatt has four production lines and each one includes an automated optical inspection (AOI) machine to check the printed circuit board assemblies (PCBA) on its products. The first pass yield (FPY) was only 60 percent and of the remaining 40 percent, 97.5 percent were false calls.

“Whenever the AOI detects a potential error, an operator must check the board manually,” says Tobias Morlock, head of process and technology (manufacturing) at Siemens Rastatt. “It requires time but it also leads to what is known in the industry as ‘alarm fatigue’ and eventually the operator will unintentionally make more mistakes and tend to be more likely to approve a faulty board, which will be discovered only later in the production process. This led to greater overhead and losses.

“Usually, we would ask our AOI experts to optimize the machine settings to decrease the level of false results. The AOI machine vendor offered a partial solution that helped to manually optimize the process. We were using that solution, but it provided limited help. When we became aware of the new Siemens Digital Industries Software solution, we tried it and were happy to see better results.”

Siemens Rastatt adopted Opcenter™ Intelligence AOI False Call Reduction (FCR) software, which helped improve their initial FPY by 42 percent without any additional effort by their AOI experts. Opcenter Intelligence is part of the Siemens Xcelerator business platform of software, hardware and services. Using Siemens Xcelerator enables customers to accelerate their digital transformation at scale.

Siemens Rastatt analyzed several artificial intelligence (AI) solutions. Most of the solutions required additional effort for integrating and developing interfaces for machines and implementing hardware, etc.

“The huge benefit of using Opcenter Intelligence AOI False Call Reduction was that we got a complete package from a responsible partner that operates on its own and provides a finished solution,” says Morlock.

“Opcenter Intelligence fits perfectly with our needs. We are always looking for innovative technical solutions and using Opcenter AOI FCR enabled significant improvement with reduced effort, which customers benefited from as well.

One of the big advantages of Opcenter AOI FCR is that it is a SaaS solution that significantly reduces the effort on our side. It was completely ready to be integrated into our AOI machines. It took less than 12 weeks to go from the first discussions to the start of commissioning. Twelve weeks later we started the operation phase successfully.”

With Opcenter Intelligence AOI FCR, an AI model is generated from AOI measurements data and operator-classified data. Concerns regarding escapes or slips are addressed in the assessment stage. Models are then validated to prove they have equal or better accuracy than the baseline.

The AI model is deployed to the shop floor on Siemens Industrial Edge devices and receives measurement data in real time from the AOI. The Industrial Edge platform provides decentralized and local data acquisition, analytics and transfer capabilities. In addition, it allows the user to deploy any software rapidly and reliably on to the shop floor, which reduces complexity and information technology (IT) costs by providing edge device and application lifecycle management (ALM) functionalities. Further, the Industrial Edge ecosystem provides secure data handling in production by using industrial grade hardware.

Using Opcenter Intelligence does not require the customer domain experts to have knowledge of Industrial Edge as it is covered by the AI lifecycle.

The AI consumes measurement data and outputs a decision: for instance, is the board a false call or potentially a real error? The result is delivered before the operator needs to check the board, saving time and effort. The AI is consistently more accurate than the operator and fewer mistakes are made deciding whether a real or false error has occurred.

Opcenter Intelligence AOI FCR is integrated into the four production lines. The AI result is seamlessly integrated into the testing station without disrupting the regular user experience of the operator.

Siemens provides full support

There were a number of keys to success to Siemens Rastatt’s implementation of Opcenter Intelligence AOI FCR: It does not require any AI expertise or user training and implementation was intuitive and rapid. The solution can be used out-of-the-box (OOTB) and the AOI experts do not experience any changes in their user experience.

The key factor is the seamless integration with the customer infrastructure and Siemens’ continual updating and refining of models. Machine learning operation services are used to continually optimize the availability and performance of models.

“The great thing about Opcenter Intelligence AOI FCR is you get the entire solution from one source,” says Morlock. “That makes it easy and fast to implement. Siemens Digital Industries Software does everything in the background. That helps us to focus our resources on more important tasks.

“Because of the smart solution from Siemens Digital Industries Software, the implementation was very quick. They provided a complete package of SaaS, including finished and tested interfaces to our AOI machine. Thanks to the remote access to our data, Siemens Digital Industries Software can work and optimize the AI in the background without any additional effort from us.”

Siemens Rastatt expects to use Opcenter Intelligence AOI FCR to drill down and configure the AOI parameters to directly impact the FPY at the source, and leverage AI to explore the routing of good boards sequentially. They are also considering using it as part of shop floor automation and for component analysis.

The huge benefit of using Opcenter Intelligence AOI False Call Reduction was that we got a complete package from a responsible partner that operates on its own and provides a finished solution.

Tobias Morlock, Head of Process and Technology (Manufacturing)

Siemens Rastatt

Egicon uses Valor and Opcenter to reduce repair rates by 80 percent while eliminating scrap

Industry: Electronics Manufacturing

Now I can get instantaneous updates on all our manufacturing processes, without leaving my desk. I know that the systems are checking that everything is okay, instead of me – so I can spend my time on innovation and improvements.

- Michele Magri, Production Manager

Egicon

High-quality electronics manufacturing

Egicon is an emerging, state-of-the-art European electronics design and production house. Based in the Modena region of Italy, the company provides high-quality manufacturing services for industrial sectors including automotive, agriculture, biomedical and aerospace.

Founded in 2009, the company’s production wing was established to produce electronic control units (ECUs) for motorcycles, racing cars and luxury automobiles, in accordance with IATF 16949 quality standards. Over time the company began to manufacture additional products including medical devices, in compliance with ISO 13485 quality requirements.

In 2015, the need to provide customers with warranty support and traceability data started the company on a digitalization journey that eventually led to full automation of its manufacturing processes.

“Our search for the most suitable manufacturing execution system led us to Mentor Graphics and Cadlog, its Italian representative,” says Michele Magri, production manager at Egicon. “Valor’s point solutions and traceability solutions were a perfect fit.”

The digitalization journey

“The automation process began with a simple data collection system and accelerated from there,” says Magri. “We invested heavily in ECAD and MCAD systems and deployed the Valor® Process Preparation software in order to achieve a single, unified flow of information between our design and production departments. This was especially beneficial in NPI execution.”

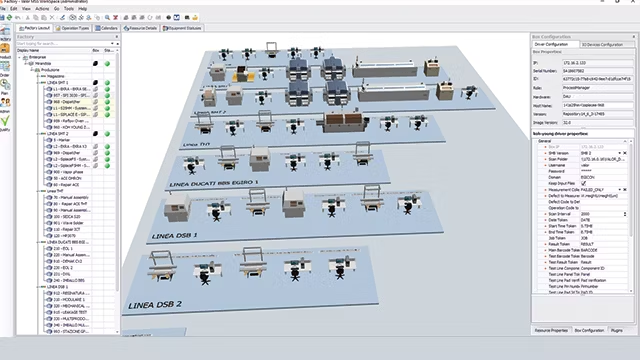

“Initially, the Valor point solutions package was used to connect our machines, warehouse and assembly and testing processes to our central database, in order to achieve traceability of materials,” Magri explains. “Soon after, we realized that the solution was completely suitable for the monitoring of productivity and overall equipment effectiveness. By 2017, all Egicon processes were connected to the Valor system, replacing all manual data collection systems and tracking KPIs in real time. In 2019, we installed the Opcenter Execution Electronics IoT software to improve data collection and gain the benefits of the greater flow of data, which allowed us to benefit from the Opcenter Intelligence Electronics analytics software. We’ve turned the paperless factory into a reality.”

With a staff of 60 and yearly revenues of €10 million, Egicon is considered one of the most interesting emerging companies in the field of technology development and production.

Opcenter™ Execution Electronics IoT software is fully integrated into Egicon’s production and quality systems, allowing continuous monitoring via the overall equipment effectiveness (OEE) dashboard, enabling managers to see the state of work-in-progress, in real time. The quality department is instantly notified regarding quality events, leading to a significant reduction in waste-related costs.

The Valor and Opcenter solutions at the core of Egicon’s production systems are part of Siemens Xcelerator business platform of software, hardware and services. Egicon releases at least 200 new product introductions (NPIs) or updates for review each year, and the Valor Process Preparation suite manages all product changes and releases.

Valor Material Verification verifies that all materials and tools are set up before assembly, improving efficiency and quality. The software also provides maximal flexibility by supporting functions such as alternate parts, an approved vendor list (AVL), free feeder positioning, dynamic alternate positions, blocked material and safe splicing.

Opcenter Execution Electronics IoT and Opcenter Intelligence Electronics provide comprehensive, Industry 4.0-ready shop floor data collection and analytics, which connect to all the processes and machines for data collection and full traceability. Customers are assured of the highest levels of traceability (IPC1782 levels three and four) at no additional cost. Egicon, which previously had a one-month lead time for quality and production reporting, now offers these services in real time. “Now I can get instantaneous updates on all our manufacturing processes, without leaving my desk.” says Magri. “I know that the systems are checking that everything is okay, instead of me – so I can spend my time on innovation and improvements.”

“Using the tools provided by Mentor Graphics and Cadlog, we are able to reduce our repair rate from 30 ppm to six, and achieved a scrap rate of zero percent in 2019,” Magri explains. “Our customers appreciate the improved levels of service, and thanks to these innovative solutions, we can often anticipate their quality system requests. This has increased our customers’ level of confidence in us and helps us to attract new business. We are using Valor point solutions to avoid manual registration of quality events, and we are using the Valor foundation for monitoring the work in progress. Elimination of scrap product is related to real-time monitoring of quality events and is a result of continuous improvements ensured by the manufacturing analytics platform.”

Moving forward in the Industry 4.0 vision, Egicon plans to leverage the ISA95 data connectivity layers to drive excellence using applications such as analytics and machine-to-machine (M2M) and other micro-solutions.

Michele Magri, Production Manager

Egicon

Industrial manufacturer reduces changeover time by 15 percent

Product: Opcenter

Industry: Electronics and Semiconductors

The Opcenter APS solution implementation significantly increased our efficiency by minimizing activities that did not bring value.

Ivan Koussarov, Division Manager, Sheet Metal

AQ Electric Radomir

Meeting demanding requirements

AQ Electric Radomir (AQ Electric) is a part of AQ Group AB (Sweden), which is a manufacturer of electrical cabinets, metal structures, electrical panels and components for global industrial customers with demanding requirements. The company has expertise in the design, production and delivery of a wide range of low voltage (LV) and medium voltage (MV) electrical cabinets as well as equipment for automation, sheet metal products and crane cabinets. The production processes also include cables and cable harnesses as well as mechanical assembly of components. AQ Electric products are used by industries such as power transmission, telecommunication, trains, food and trucks. The company has at its disposal a machine workshop with personnel that has more than 50 years of experience, two painting lines, a welding workshop for ferrous and nonferrous metals and machines for cutting, bending and stamping of sheet metal products.

Further, there are workshops for assembling and testing of electrical panels up to 20 kilovolt (kV) according to the International Electro-technical Commission (IEC) 61439 and for production of cable products as well as a line for cataphoresis coating. AQ Electric has a design team for metal and mechanical construction and design of electrical panels. AQ Electric has an annual turnover of €34.6 million, 750 employees and a factory with a production area of 22,000 square meters.

Challenges

The production is organized in two segments: sheet metal components and electrical cabinets assembly. Planning is key due to the complexity and variability of the produced parts. The management team is focused on production optimization, cost efficiency and integrating new technologies to provide the best product quality. They knew they needed a specialized software solution to satisfy these needs.

Claes Meligren, the AQ Group chief executive officer (CEO), says, “AQ aims to be a world leader in cost effectiveness, quality, security of supply, alertness and service. In a word, ’reliable.’”

The main challenges are the complexity of the production processes and the products manufactured, the huge number of production orders, the availability of a lot of primary resources and additional constraints such as instruments, equipment and operators. The great number of resources and constraints interfered with the ability to generate an effective production schedule.

Many AQ Electric users were engaged to generate production schedules by department and synchronizing these micro plans was a serious challenge. The appearance of each unplanned event such as a breakdown or late material delivery ruined the production schedule and required significant time for recovery.

The supply chain department did not receive proper information on what materials were needed and when, thus leading to overstock.

The solution

All these pains led to the decision to implement an advanced planning and scheduling (APS) solution. The aim was to eliminate waste (scrap, poor quality, over production, unneeded areas, stock, extra transports, etc.) to increase profitability and show environmental concerns as well as increase production efficiency.

After a detailed analysis of the solutions available on the market and assisted by SmartApps Ltd – a Siemens Silver partner with expertise in advanced planning and scheduling – AQ Electric selected Opcenter™ APS software Ultimate Edition as the best option to fit their needs. Opcenter APS is part of the Xcelerator™ portfolio, the comprehensive and integrated portfolio of software and services from Siemens Digital Industries Software.

SmartApps is accredited as a Siemens Smart Expert for the Opcenter APS portfolio. It has developed integration modules for Opcenter Advanced Scheduling with many enterprise resource planning (ERP), manufacturing execution system (MES) and supervisory control and data acquisition (SCADA) systems in a variety of industries.

The implementation

During the implementation, a detailed analysis of the production model and processes in the company was made and the main sources of waste were identified. A strategy for achieving a balanced optimization was developed. Optimization algorithms, specific for each department, were developed, keeping in mind the specific requirements and additional constraints. An overall rule for synchronized scheduling of all company departments was created. The SmartApps team also developed integration with the existing ERP system.

Results

Due to the Opcenter APS implementation, only one planner is now responsible for production scheduling. By using the optimization algorithms in each department, the efficiency and internal on time in full (OTIF) have increased.

The changeover times decreased by 15 percent while the internal OTIF for most departments increased by up to 98 percent.

The implementation of Opcenter APS led to better communication and collaboration between departments and improved work synchronization.

“The Opcenter APS solution implementation significantly increased our efficiency by minimizing activities that did not bring value,” says Ivan Koussarov, division manager, sheet metal, AQ Electric Radomir. “The system gives us a glance at the future and the ability to identify potential problems and apply preventive measures before their appearance in order to avoid or decrease the damages.”

The system gives us a glance at the future and the ability to identify potential problems and apply preventive measures before their appearance in order to avoid or decrease the damages.

Ivan Koussarov, Division Manager, Sheet Metal

AQ Electric Radomir

Figure 4® 3D Printer adds Precision and Productivity for Swedish Design Agency, Splitvision

Product: Frigure 4

Industry: Electronics and Semiconductors

The Stockholm-based product design agency, Splitvision Design, is among the first Nordic companies to invest in 3D Systems’ Figure 4® Standalone 3D printer. With its investment, the company can now evaluate fitting and assembly with incredible accuracy before moving in to serial production. At the same time, the Figure 4 Standalone gives the company a productivity boost in prototyping.

Splitvision, a Nordic industrial design agency, adopts Figure 4 3D printing

Since its inception some 30 years ago, Splitvision Design (then named Formbolaget), has done a wide variety of design work – from point-of-sale solutions to bespoke truck cabs. Today, it works almost exclusively with industrial design for technology-intensive companies in the medtech and automotive verticals. The thing that makes Splitvision unique is that it offers services that stretch beyond the average design agency – with a focus on manufacturing and logistics.

“Even though we set out as a traditional design agency, over the years, we’ve seen that we get a better and more controllable manufacturing process when we focus on these steps,” says Lukass Legzdins, R&D manager at Splitvision Design.

“We went from just working with design, up to engineering, planning, purchasing and logistics,” adds Legzdins. We also have offices in China that handle the day-to-day contact with manufacturing over there. Here, we also perform quality control and monitor the supply chain. All in all, this creates really good results, and enables us to add a lot more value to manufacturing even at the concept phase.”

Better prototyping with Figure 4 3D printing

Product designs include cases for delicate electronics such as hearing aids

This type of turnkey commitment is also reflected in prototyping. With its new Figure 4 Standalone 3D printer from 3D Systems, installed by PLM Group, the company is expanding its services portfolio and adds competence to product development. Now, Splitvision can offer better physical prototypes, printed inhouse. At the same time, with the help of its high-quality 3D printed parts, they can optimize the data needed before ordering injection molding tools.

Before using 3D printing, prototyping was tedious and manual work. The company worked with materials in foam and plastics to explore geometries and ergonomics, sometimes in full scale. Prototypes for functional tests or for customer review were bought from a third party supplier, either from Sweden or China.

“Then, all of a sudden, there was this period when we had a massive amount of products under development, and everything basically piled up as we waited around for our 3D printed prototypes,” said Legzdins. “That’s the moment we decided to invest in an inhouse 3D printer, and luckily, it coincided with us discovering the Figure 4.”

Splitvision had no prior experience with Figure 4 technology, which is an offshoot of SLA, stereolithography. It had previously gone under the radar, as SLA parts rarely displayed the mechanical properties the company needed. But with the Figure 4, the technology suddenly became very interesting.

Additive Beyond Expectations

Splitvision has worked for several years with a number of innovative medtech companies, including several hearing aid brands. The production often consists of associated products, such as hearing aid casings, as the companies have optimized their production lines for their core products. But hearing aid casings can be tricky to design and manufacture. They need to protect the hearing aid, be of excellent quality and reflect the brand, and be durable over time.

“3D Systems’ Figure 4 ELAST-BLK 10 material has the same properties as rubber. It’s beyond our expectations,” says Lukass Legzdins, R&D manager, Splitvision.

The casings that Splitvision design and manufacture are partly made of TPE or silicone. The soft lining keeps the hearing aids in place and protects them from everyday wear and tear. But 3D printing TPE and silicone is next to impossible if you want good results. The only option is to mold, which is a big challenge when you want to evaluate design and investigate potential assembly challenges.

“After receiving a number of print samples from PLM Group, we realized that 3D Systems’ Figure 4 ELAST-BLK 10 material had the same properties as rubber. It was beyond our expectations,” Legzdins. “The material enables well-defined surfaces. We can see detailed shapes and facets. But most importantly, it allows us to evaluate the assembly process to identify potential challenges. Overall, it’s an excellent way for us to get confirmation of the geometry, while at the same time enabling our customers to do their own user tests.”

Combined with using the rigid Figure 4 TOUGH-GRY 15 material, Splitvision can add more detail to their parts. With the high resolution of the printer, there’s rarely any need for finishing.

“One could say that our Figure 4 takes us one step closer to reality,”said Legzdins. “Previously, we added more margin to our CAD files before ordering tools. Now, we can skip one or two steps in the development phase, as we have much more geometrical data from the 3D printed prototypes. The result is fewer incremental changes and adjustments to the tool.”

The Figure 4 printer also reflects Splitvision’s core values in product development.

“When we work with customers, we want to add our competence in design and manufacturing, wherever we see that we can optimize function. We use this knowledge to raise the quality of the product to new levels,”said Legzdins.

Accelerating turnaround of CFD simulations

Product: Simcenter

Industry: Electronics and Semiconductors

Heraeus Noblelight GmbH has been developing specialty light sources since the invention of the quartz glass lamp in 1904. Light, whether ultraviolet (UV), infrared (IR) or middle wave range, is at the heart of everything they do. Located in Germany, the company has harnessed the power of light to solve a wide range of challenges in the manufacturing and process industries. They also design and manufacture consumer products like the Soluva® air purifier, for removing airborne viruses including the Coronavirus disease of 2019 (COVID-19) from healthcare settings, public transport and classrooms.

Engineering simulation is not only used during the product development phase, but also to understand the best way to deploy products in the field. “We use CFD simulation to help our customers understand their processes and where to locate our UV or IR emitters to make them most effective,” explains Dörte Eggers, simulation engineer at Heraeus Noblelight. Eggers continues, “sometimes a customer already has a process in operation that is not working optimally, so we also use simulation to troubleshoot and find ways to improve it.”

Modeling the complexity with CFD

Heraeus Noblelight products cater to a wide range of industrial processes, from curing paints and adhesives using precision IR emitters, to water and air disinfection equipment using ultraviolet C (UV-C). A range of modeling techniques are required to capture the prevalent physics regimes in each case.

“We selected Simcenter STAR-CCM+ for CFD analysis because it delivers a wide range of physics modeling options in a flexible and easy-to-use package,” says Dr. Larisa von Riewel, computer-aided engineering (CAE) group leader. “Our core workload is thermal management simulation. However, we often need to include additional physics like multiphase flow and particle tracking.”

Seeing the invisible

Since many of their products operate outside of the visible light spectrum, computational fluid dynamics (CFD) simulation is a valuable tool for verifying specific applications, tailored to each customer’s process. Therefore, CFD has become a routine part of the sales process and requires a rapid turnaround of simulation work. This provides confidence that the construction team will deliver a high performing product and add significant value for customers.

As well as making invisible light visible, using CFD analysis makes the unmeasurable measurable. “In some cases, running physical trials is very expensive and sometimes impossible,” states von Riewel. “Taking our IR emitters as an example, simulation is essential as it enables us to estimate parameters we cannot physically measure. Understanding this behavior is critical for achieving the functionality and lifespan we need from the devices.”

Communicating the insights gained from simulation to a range of stakeholders is also an important part of the process. “Every new release of the software has additional post-processing features and we find these very useful to present simulation data to customers in the context of their equipment and processes,” says von Riewel.

Going faster with Simcenter Cloud HPC

Today, most CFD simulation at Heraeus Noblelight is done in-house using a large on-premise workstation. However, during busy periods, the team needs to tap into additional resources by outsourcing simulation work. The need to scale up and down quickly makes it difficult to manage licensing costs to cover short periods of use and to ensure that resources are used efficiently.

Over the past few months, Heraeus Noblelight has been an early-access user of Simcenter ™ Cloud HPC software, a new hybrid software as a service (SaaS) product, which enables simulation runs to be launched on cloud infrastructure directly from Simcenter STAR-CCM+ ™ software. These are part of the Xcelerator portfolio, the comprehensive and integrated portfolio of software and services from Siemens Digital Industries Software. By purchasing hardware and software in the same transaction and paying only for what is used, Heraeus Noblelight sees potential to gain more efficiency by being able to instantly access high performance computing (HPC) resources from anywhere, at any time.

Accessible

“When we are working with remote simulation teams, we often find we do not have HPC resources where we need them to be,” continues von Riewel. “Therefore, Simcenter Cloud HPC would enable us to speed up collaborative projects. We also would not need to worry about license costs going to waste if a project finishes sooner than expected.” Using the cloud means the HPC resources are readily accessible by all team members. “I would say the interface is user friendly and intuitive, with several options for monitoring the runs,” continues von Riewel. “Transferring the simulation files was fast and straightforward.”

For von Riewel and Eggers, simulation is a small part of their working day. Therefore, they are not able to devote as much time as they would like to researching and testing new models and features. Therefore, they rely on the expertise of the Simcenter customer support team and their dedicated support engineer (DSE). “We are always under time pressure. When we face new challenges, we prefer to go to our DSE who explains relevant new features and how they will benefit us. This is a great time saver,” von Riewel explains.

Flexible and scalable

As well as facilitating collaboration with remote teams, Eggers also sees potential to leverage cloud resources to run more ambitious simulations or broaden the scope of projects while still meeting tight deadlines. “In some cases, we need to run bigger models to capture more detail or run more simulations in the same amount of time. Simcenter Cloud HPC gives us that flexibility.”

Secure

Heraeus Noblelight frequently works on projects involving customer proprietary processes and technologies, so data privacy and security are critical for their business. “When we sign agreements with customers, there are usually terms restricting how and where we store and work on their data,” explains von Riewel. “Of course, all stakeholders need to be sure their data is safe. I expect attitudes will gradually change as the world adapts to this new way of working.”

Simcenter Cloud HPC is built on Amazon Web Services (AWS) cloud infrastructure and follows best practices developed by AWS and Siemens for developing and operating multi-tenanted SaaS applications. Users have complete control over data sovereignty and retention and the product will also go through the International Organization for Standardization (ISO) 27001 and System and Organization Controls 2 (SOC2) Type 1 certification.

“I am confident that Siemens is diligent in maintaining the necessary policies and certifications to satisfy us and, importantly, our customers,” von Riewel concludes.

Looking to the future

When asked about how running CFD simulations in the cloud might impact their work in the future, Heraeus Noblelight sees flexibility and accessibility as key benefits. “Since the pandemic, there has been a large shift toward remote work, which means there are not always people available to access workstations in the office when something goes wrong,” says von Riewel. “Being able to work on projects from anywhere in the world is a dream and I feel this is the way humanity should go.”

Von Riewel also sees the ability to scale up and down instantly as a future competitive advantage. “The world continues to develop and everything is increasing in complexity. Models are becoming more accurate and we need to capture more physical realism. You can guarantee we will frequently require more powerful HPC resources in the future. Simcenter Cloud HPC offers that agility, which translates to a more competitive offering for our customers.”

AT LOFTY HEIGHTS: 3D SCAN OF A WIND TURBINE BLADE

Product: HandySCAN

Industry: Energy

The maintenance of wind turbines, and whole wind farms, is a challenge. Normally wind turbines are designed to operate for 20 years. During these 20 years they are subjected to all kinds of weather conditions and heavy loads, but thanks to modern acquisition technology and advanced numerical models, such conditions can be addressed and even turned into increased annual energy production.

To optimize the production throughout their lifetime, their operating conditions must be understood in detail and then regularly maintained on this basis. The goal is to keep wear and tear under control and prevent the generation of unexpected vibrations and/or weak points that could compromise the integrity of the turbine structure and components, all while maximizing the power production.

The Spanish company Nabla Wind Power is part of the Nabla Wind Hub group, an independent service provider that offers unique and multitechnology solutions for wind farms life extension, performance improvement and maintenance optimization.

Digitalization under harsh conditions

In 2020 Nabla Wind Power was asked to extend the rotor blades of a wind turbine to increase the performance of the existing installation by 10%. To do this, the last meters of one rotor blade had to be digitalized so that the blade extension could be subsequently designed. In a first attempt, terrestrial laser scanners were used for the digitalization. But Nabla needed a considerably lower uncertainty in the measurements and therefore started to look for an alternative solution and finally asked Creaform Services to support them.

The best portable 3D scanner suited for this task was the HandySCAN 3D | BLACK. Thanks to its dynamic referencing feature, it can digitalize precisely in harsh conditions. Vibrations do not affect the results and the uncertainty of the measurements is far less than a millimeter. As the task had to be realized directly on the wind turbine, a Creaform Application Engineer trained two industrial climbers from the company Asaken and taught them how to use the HandySCAN 3D. Then the climbers went up to the top of the wind turbine at 130 meters, had to get out of the hub and rappel down to 65 meters above the ground.

The first thing to do was to stick targets on one of the rotor blades on the last 7 meters. These targets are used as reference points by the HandySCAN 3D. Then they started the scan. While one of the industrial climbers was wearing the laptop, the other was handling the scanner. Meanwhile, the Creaform Application Engineer was overviewing the scan from the ground via Teamviewer. At this height, wind conditions are always an issue and several times, it became so windy that the works had to be stopped due to the strong winds. Also, some technical issues of the wind turbine itself disturbed the scan process: for example, the rotor blocked and couldn’t be brought into a vertical position. But finally, the scan was performed successfully.

The acquisition software used was VXmodel, a module of VXelements. The generated .stl file was then transferred into CATIA for reverse engineering.

Nabla’s Head of Operation, Eder Murga, was really pleased with results: “The handling of the provided service was professional, both from Creaform and Asaken. Despite the harsh conditions and many interruptions due to strong winds, everyone involved faced the change in conditions with great flexibility and, in the end, we managed to get the perfect results. A hand-held, self-referencing measuring system such as the HandySCAN 3D is the only way to carry out such a measurement in a harsh environment.”

-640x360.jpg?w=900&fit=max&q=60&dpr=1&auto=format)

-640x360.jpg?w=900&fit=max&q=60&dpr=1&auto=format)

-640x360.jpg?w=900&fit=max&q=60&dpr=1&auto=format)

-640x360.jpg?w=900&fit=max&q=60&dpr=1&auto=format)

-640x360.jpg?w=900&fit=max&q=60&dpr=1&auto=format)

-640x360.jpg?w=900&fit=max&q=60&dpr=1&auto=format)

-640x360.jpg?w=900&fit=max&q=60&dpr=1&auto=format)