Industry: Automotive & transportation

How NX CAD/CAM revolutionized synchronizer ring manufacturing

The Client

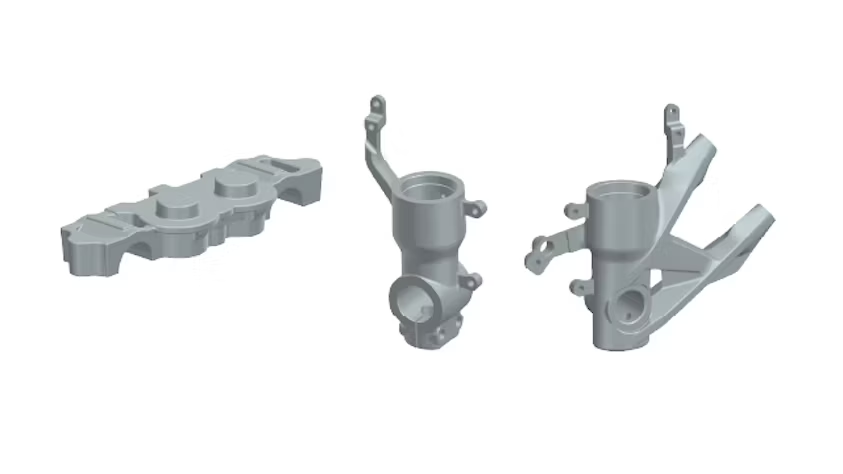

ANAND CY Myutex Automotive (ACYM) is a specialized manufacturer of synchronizer rings for the automotive industry. These components are essential in synchromesh gearboxes, advanced transmission systems that enable smooth gear changes in passenger and commercial vehicles.

The Challenge

ACYM faced multiple obstacles that limited their responsiveness and competitiveness:

Technical Issues:

- Design and production teams working in silos

- Outdated CAD software without collaborative capabilities

- Incompatibility with client file formats

- Imprecise generation of complex surfaces

- High manufacturing error risks

Business Impact:

- Extended development cycles

- Delayed customer deliveries

- Risk of costly machinery collisions

- Loss of competitiveness in an expanding market

“With original equipment manufacturers focusing on high-performance vehicles and expanding electric vehicle offerings, the demand for advanced transmission solutions is increasing” – Pranav Rawal, General Manager at ACYM

The Solution: NX CAD/CAM

In collaboration with DDSPLM (Siemens Digital Industries Software partner), ACYM implemented NX™ software, part of the Siemens Xcelerator business platform.

Key Implemented Features:

- Synchronous Technology: Parameter adjustment without historical data

- CAD/CAM Integration: Single source of truth for the entire process

- Advanced Automation: Customizable tools for toolpath creation

- Universal Compatibility: Support for multiple file formats

- Integrated Simulation: NC program verification without damage risk

Quantifiable Benefits

Operational Efficiency:

- 40% reduction in design and production times

- 40% reduction in concept-to-delivery time

- 30% savings in operational costs

Technical Improvements:

- Elimination of manual transfer errors

- Greater precision in complex surfaces

- Better machining process control

- Significant reduction in material costs

Enhanced Collaboration:

- Design and production teams working in an integrated manner

- Smooth communication with international clients

- Complete version control and traceability

Client Testimonial

“The synchronous technology in NX is particularly beneficial for working with imported data. It allows us to adjust hole sizes or shift surfaces on models without historical data. The same way our synchronizer rings deliver a smooth gearbox experience, using NX synchronous technology provides us the flexibility to quickly adjust parameters and implement design changes as needed.”

Pranav Rawal, General Manager, ANAND CY Myutex Automotive

Key Lessons

- Integration is fundamental: Eliminating silos between design and manufacturing generates exponential efficiencies

- Technical flexibility matters: The ability to work with diverse data is crucial in global supply chains

- Measurable ROI: Efficiency improvements translate directly into competitive advantages

- Scalability: Solutions must grow with market demands

Why this case matters

In a constantly evolving automotive market, where electrification and efficiency are priorities, ACYM demonstrated that digital transformation is not just an option, but a strategic necessity.

Is your company facing similar manufacturing challenges? At Goaltech, we help companies identify and implement the technological solutions that transform their operations.

Contact our team to explore how we can accelerate your digital transformation.