Industria: CFD

CFD for clean air: How simulation is transforming spaces and processes.

Until 2020, Computational Fluid Dynamics (CFD) for ensuring clean air was not a topic that captured the attention of the general public. However, with the COVID-19 pandemic, the need for clean and healthy air became a matter of global concern. This led to CFD reaching the mainstream media. Although public attention has been reduced following the pandemic, the need for purified air in public facilities, offices and transportation remains crucial. Moreover, it is not only humans who require high standards of air quality; many industries need controlled environments to avoid contamination that can affect the production of goods.

CFD simulation is an essential tool in this ongoing challenge. Simulation software from Siemens’ Simcenter portfolio is used in a variety of applications to ensure that air is purified, improving both our breathing and manufacturing processes.

Three ways CFD helps ensure clean air

While CFD simulations do not replace public health guidelines, they can be useful in three key areas:

- Understanding pollutant transport and mitigation 2.

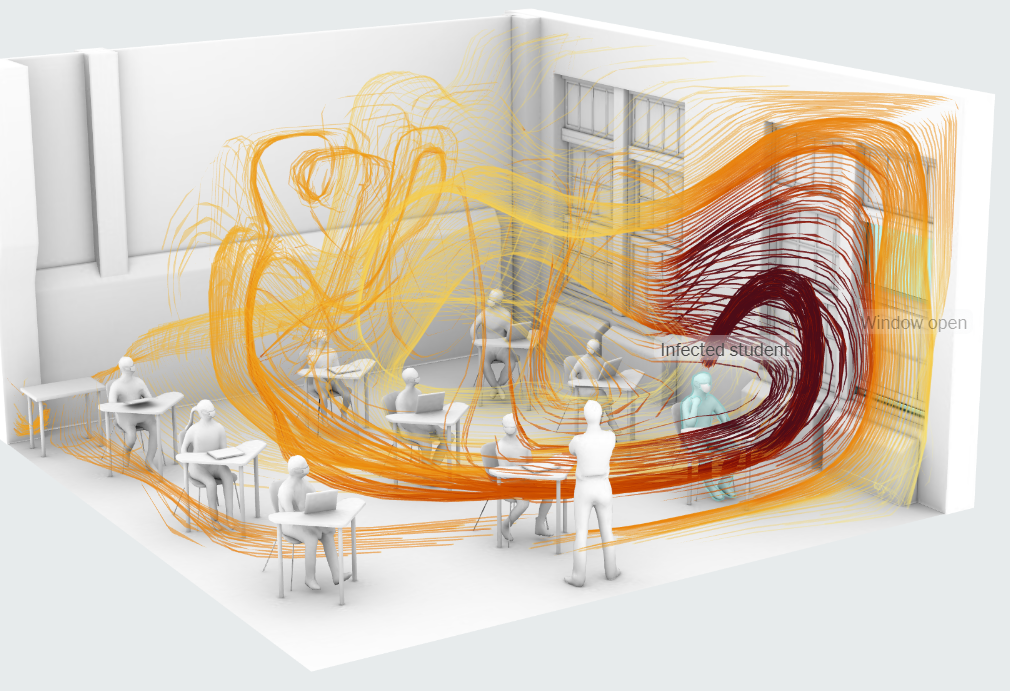

CFD allows modeling the movement of aerosols and particles in space and time. This is especially useful in controlled indoor spaces such as rooms, automobiles, trains, airplanes, clean rooms, and food factories. - Improve and redesign indoor spaces for safety.

With CFD, multiple configurations for ventilation systems can be analyzed, ensuring efficient removal of particulate contaminants in indoor spaces. It is also possible to optimize the location of air purifiers and air barriers. - Designing equipment to remove hazardous substances and purify air.

CFD enables the design of more efficient air purification devices used in public buildings, transportation and industrial environments.

CFD case studies for clean air

Public transportation

- Airbus: Used Simcenter STAR-CCM+ to model the transport of cough particles in aircraft cabins, evaluating the effectiveness of face masks.

- Norton Straw:** Analyzed ventilation strategies in trains, such as opening windows or installing plastic barriers, optimizing passenger safety.

Buildings

- HOLT Architects:** Redesigned office spaces to reduce airborne virus transmission. Simulations evaluated the effectiveness of HVAC systems, window openings and the use of disinfection devices.

- JB&B:** Showed how opening windows in classrooms dilutes contaminants, helping to minimize the risk of contagion in schools.

Industrial production

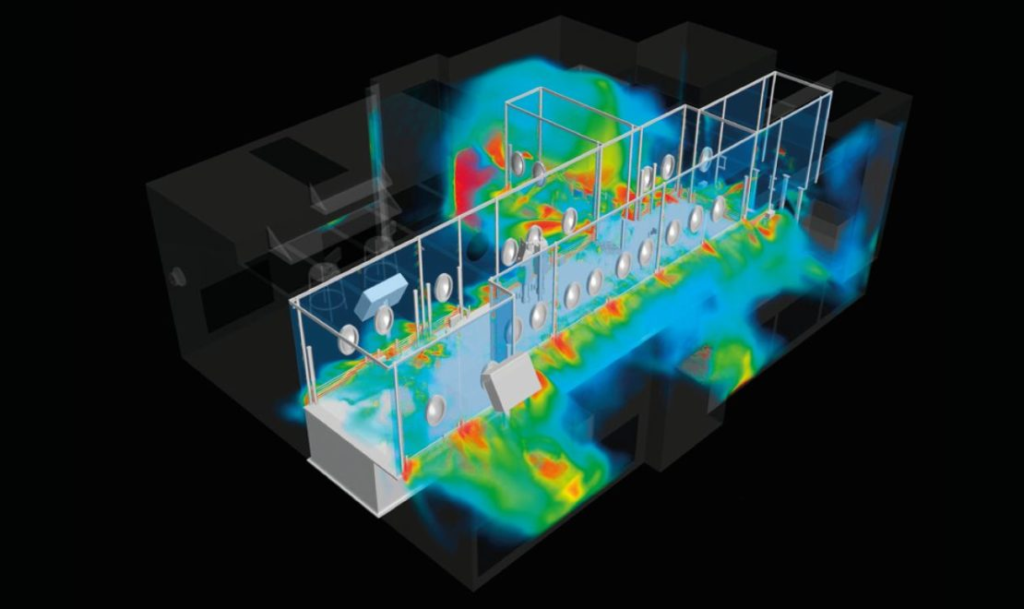

- FS Dynamics:** Developed an advanced methodology to avoid contamination on lithography machines in the semiconductor industry.

- Creaform Engineering: Simulated vaccine filling lines in clean rooms, ensuring regulatory compliance and minimizing economic losses.

Beyond Human: Purification in Industrial Processes

In addition to protecting people, CFD simulation plays a key role in maintaining hygienic standards in the production of food, drugs and other sensitive goods. Companies such as Excelitas Noblelight and Clean Air Limited have used CFD to design innovative devices, from UVC air purifiers to fume hoods, improving both efficiency and sustainability.

In short, Computational Fluid Dynamics not only helps improve the quality of the air we breathe, but also transforms key processes in multiple industries. Ready to explore what CFD can do for you?