Industry: Robotic

Tackling the challenges of complex automation in wiring

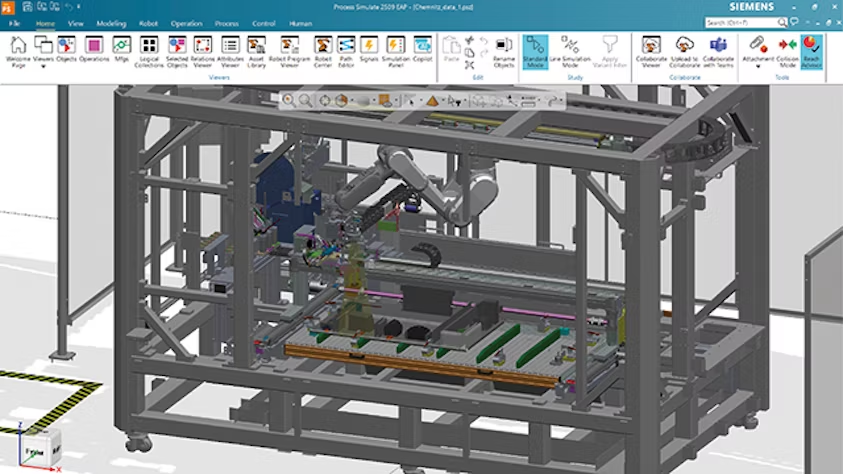

Founded in 1999 and headquartered in Zur Yigal, Israel, Polygon Technologies has become a leading name in robotic engineering, specializing in advanced automation solutions for industries such as automotive, aerospace, electronics, and industrial manufacturing. Their latest innovation, Wirebot, is transforming the way wire harnesses are assembled in control cabinets — and it’s all made possible with Process Simulate from Siemens’ Tecnomatix® portfolio.

As Omer Einav, CEO of Polygon Technologies, explains:

“Using Process Simulate enables WireBot to predict potential issues in the design phase, reducing the risk of delays and improving the quality of the final product.”

A new approach to an old challenge: complex wiring automation

Handling flexible components like wires and fibers has long posed a challenge for traditional robotics. Electrical panel wiring, in particular, has typically been a manual, error-prone, and time-consuming process. Polygon set out to change that with Wirebot, a robotic system designed to outperform human precision in wiring tasks.

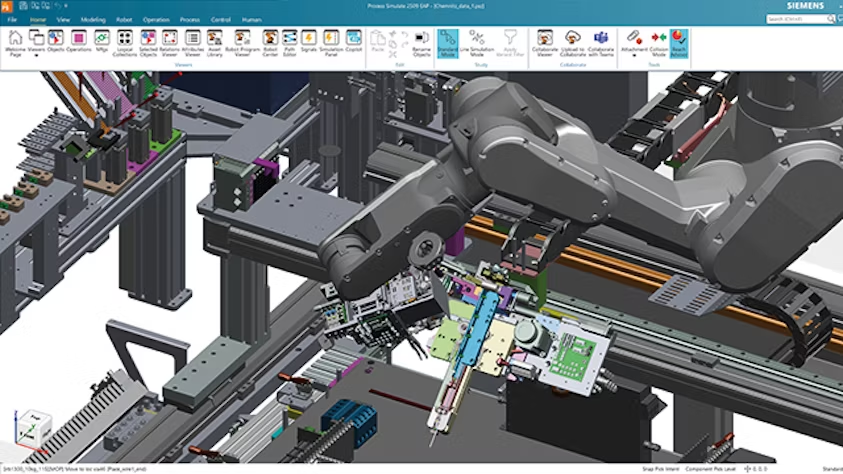

Thanks to Process Simulate, Polygon was able to virtually test and validate complex wiring scenarios before production, optimizing cable routes, avoiding collisions, and streamlining workflows. The result: faster production cycles, fewer errors, and up to 10% savings in copper material, significantly cutting costs and waste.

The key: digital twin, AI, and advanced simulation

Developing Wirebot required recreating human dexterity through cutting-edge technologies like haptic feedback, machine vision, dual-arm coordination, and advanced data processing. The resulting system merges robotics, artificial intelligence, and digital twin technology — made possible through Siemens’ Process Simulate.

“By integrating Process Simulate with WireBot, we provide customers with cost-effective component layouts in the design phase, enhancing wiring efficiency, saving time, and boosting productivity,” Einav says.

Results: precision, efficiency, and scalability

By simulating the process beforehand, Polygon reduced production cycle time by 30%, improved wire positioning accuracy, and minimized rework. Wirebot was also seamlessly integrated into existing manufacturing workflows, increasing overall operational efficiency.

The success of Wirebot has led Polygon to continue exploring new applications for Process Simulate, believing that virtual commissioning and digital twin technology are shaping the future of robotic automation.

Conclusion

The Wirebot success story is a testament to how advanced robotics and Siemens simulation technologies can solve complex challenges, drive productivity, and optimize resource usage. With Process Simulate, Polygon has entered a new era of automated wire harness assembly — and solidified its role as an innovation leader in smart manufacturing.