Industria: Manufactura aditiva

This blog series explores key lessons from my visit to Big Metal Additive (BMA), an advanced manufacturing shop in Denver, Colorado, that integrates Siemens NX for Manufacturing software and hardware for hybrid machining. This methodology, which combines additive and subtractive processes, enables the production of parts once considered impossible. However, mastering this workflow requires a hybrid skill set, where employees must efficiently operate diverse machinery and software. In this blog, we will delve into the essential skills and key machining trends in the industry.

Big Metal Additive: Innovation in Additive Manufacturing

I recently visited a leading industrial additive manufacturing customer, Big Metal Additive (BMA), which uses Siemens Additive Manufacturing software. BMA is a specialized metal 3D printing shop that integrates welders with 5-axis CNC mills to explore new frontiers in manufacturing. Their work often pushes boundaries, serving both private companies and government agencies to replace traditional processes, build intricate geometries, and conduct material testing.

The Growing Need for Hybrid Skills

A few months before visiting BMA, I spoke at a technical education conference, emphasizing the need for educational institutions to adapt their training programs to modern manufacturing. I reinforced that companies should break down silos and train employees across multiple disciplines—machining, welding, and toolmaking—especially as technologies like additive manufacturing, robotics, and automation become more prevalent.

BMA exemplifies this shift. It is not just a machine shop—it is a hybrid manufacturing powerhouse that embraces cross-functional expertise.

The Power of Hybrid Machining

Hybrid machining integrates additive and subtractive processes, allowing manufacturers to reinvent production workflows. While 3D printing has advanced significantly, it still cannot fully replace traditional methods. However, combining it with milling or turning enhances efficiency and expands design possibilities.

From a workforce perspective, this requires more than just welders, machinists, and programmers—it demands multi-skilled employees who can adapt to different tools and equipment. The future belongs to versatile engineers who can operate across domains.

CNC Meets Robotics: A Powerful Combination

BMA’s shop floor is a fusion of technology, featuring both 5-axis CNC machines and articulated robots capable of welding and machining. Engineers must navigate G-code-driven CNC machines alongside six-axis robotic systems with SINUMERIK controls—each with vastly different programming languages and degrees of freedom.

One engineer at BMA was hired for his CNC background but was tasked with learning robotics from day one. He embraced the challenge and is now an expert in both fields—a testament to the adaptability required in modern manufacturing.

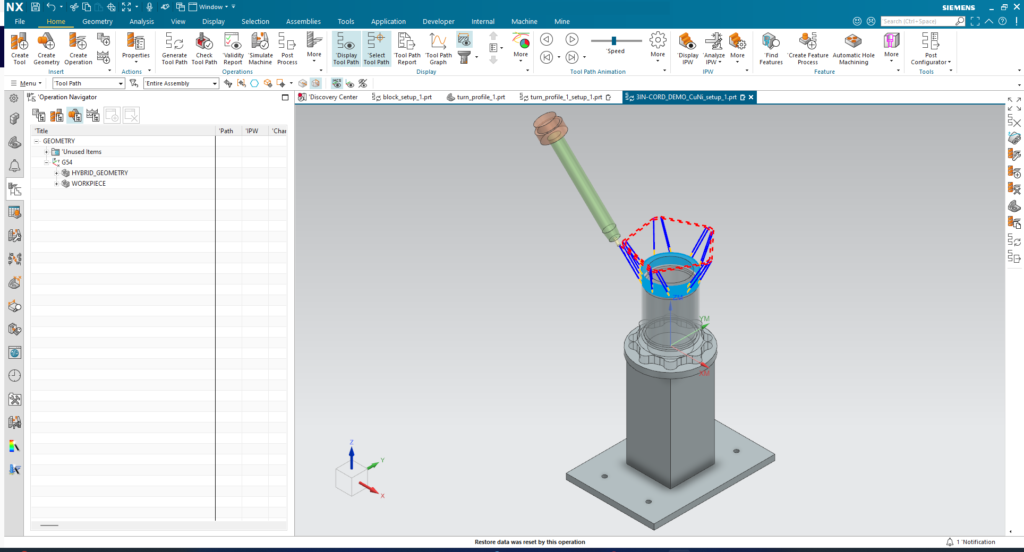

Software as the Driving Force

BMA’s hybrid operations rely on multi-functional CAM software. Siemens NX Multi-Axis Deposition enables programmers to create both additive and subtractive toolpaths within a single environment. This means engineers must understand both processes and synchronize them for successful builds—a critical step in creating a digital twin for hybrid machining.

At BMA, welding expertise is not limited to hands-on operations—it starts in the software. Engineers like Jordan factor in heat dynamics while programming additive toolpaths. Miscalculations in layer height can disrupt a build, but experienced engineers adjust settings in NX for Manufacturing to ensure success.

BMA does not rely on intuition alone. Engineers meticulously record process data, tracking voltage, amperage, and temperature during builds. This data is stored in a database, allowing for process optimization and repeatability. Many BMA customers seek to explore additive manufacturing’s potential—whether to create complex geometries, reduce lead times, or supplement production. Each project involves extensive testing, often requiring destructive analysis like tensile strength testing. Even tasks like wire EDM cutting—traditionally handled by specialists—are now done by multi-skilled engineers.

The rise of hybrid machining raises fundamental questions about workforce training. Should technical schools restructure their programs toward certification-based models that cover a wider range of skills? Should degree programs become more flexible, allowing students to mix and match courses across disciplines? Education must evolve sooner rather than later.

The Future of Hybrid Manufacturing

BMA’s engineers embody the versatile workforce of the future. Their ability to blend skills across machining, robotics, and data analysis creates a dynamic, resilient manufacturing environment.

As additive manufacturing continues to evolve, shops like BMA will shape the next era of production. I can’t wait to see what they achieve next. Stay tuned for my next blog, where I will continue exploring the future of hybrid manufacturing and industry trends.