Industriy: Agricultural machinery.

Crucianelli, an Argentine manufacturer of seeders with nearly 70 years of history, has embarked on a deep digital transformation with the goal of becoming one of the top five seeder manufacturers in the world by 2030. To achieve this, the company adopted the full Siemens Xcelerator portfolio, redefining its design, simulation, and manufacturing processes.

From Family Workshop to Innovation Leader

Founded by Don Nazareno Crucianelli in Armstrong, Santa Fe, the company began as a small workshop repairing agricultural machinery. Today, under the leadership of the third generation, Crucianelli blends tradition, sustainability, and technology to tackle modern agricultural challenges such as climate change, labor shortages, and the pressure to increase productivity sustainably.

The Solution: Siemens Xcelerator

With support from partners Simecanic / X-Plan and Descar Argentina, Crucianelli implemented a comprehensive solution based on:

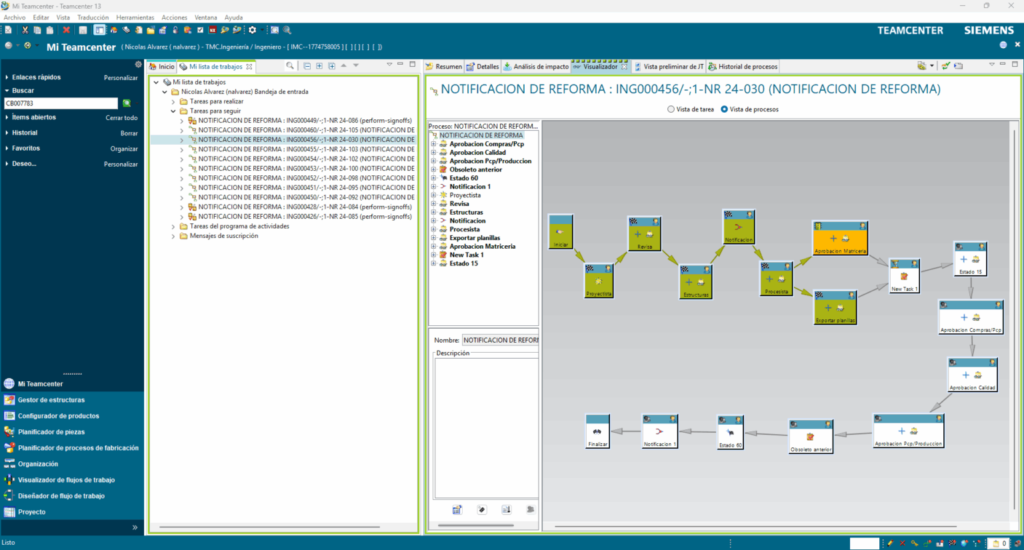

- Teamcenter as the PLM backbone, integrated with SAP.

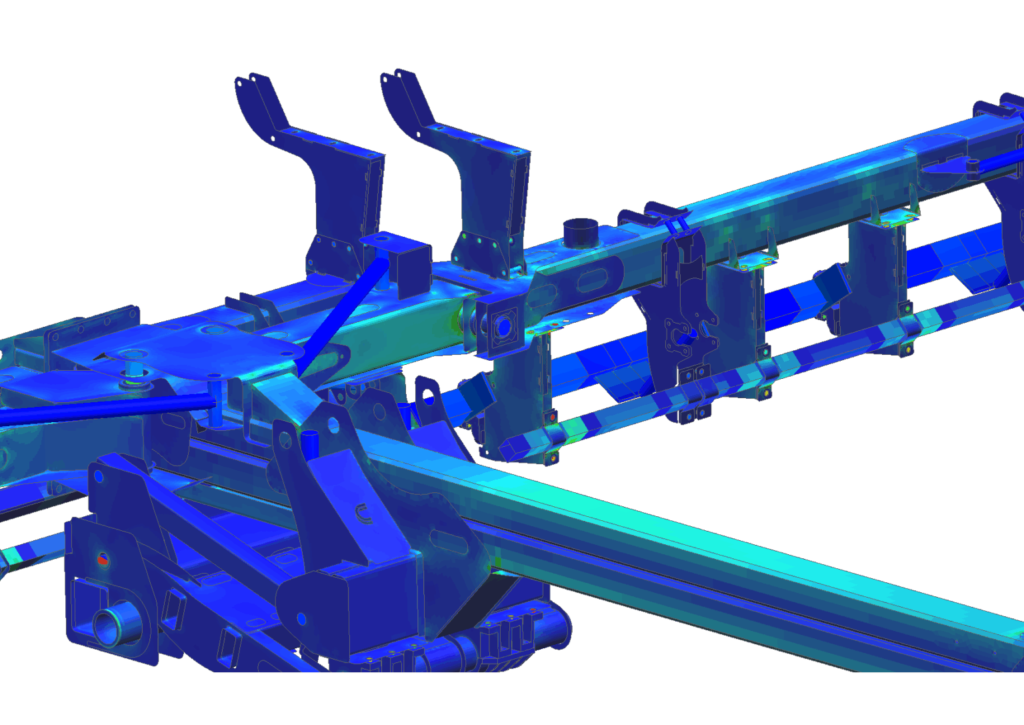

- Simcenter 3D for structural and motion analysis.

- Designcenter NX for advanced CAD design.

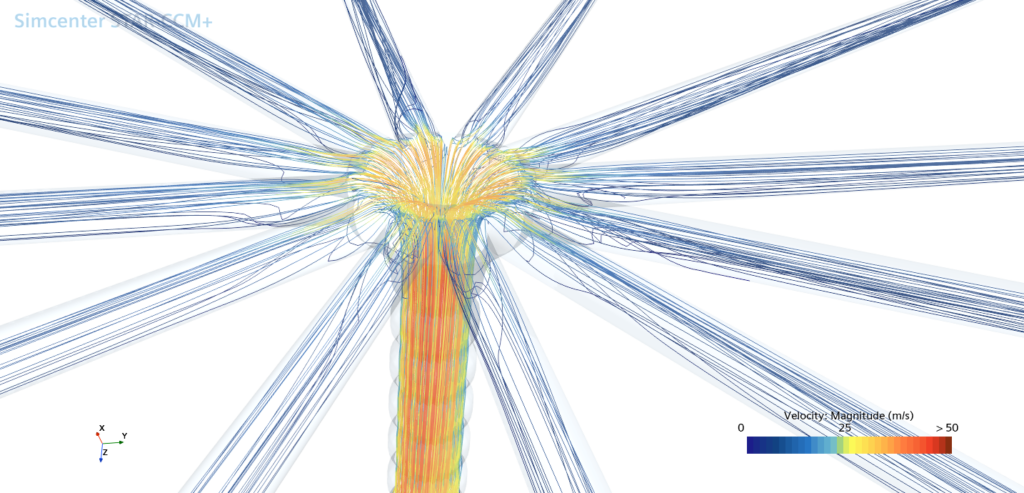

- Simcenter STAR-CCM+ for CFD-DEM simulations of seed distribution systems.

- Tecnomatix Plant Simulation to digitize manufacturing processes.

Flagship Project: The Dómina Seeder

The Dómina is Crucianelli’s first seeder developed entirely in a digital environment. The engineering team built a FEM model with over one million elements (1D, 2D, and 3D), simulating transport and field conditions. With Simcenter 3D, they optimized load distribution, validated structural integrity, and significantly reduced the need for physical prototypes.

A dual-track simulation strategy was applied: one team focused on motion analysis, while another handled structural validation. The integration between NX and Simcenter enabled early design decisions and faster iterations.

Key Results

- Over 40% reduction in development time and physical testing.

- Complete digitalization of design, manufacturing, and product configuration.

- Performance optimization of new and existing machines, such as the Plantor, using CFD-DEM simulations in STAR-CCM+.

Beyond Design: Digitizing the Factory

Crucianelli is also digitizing its production plant using Tecnomatix Plant Simulation, aiming to optimize processes, logistics, and resources. The long-term goal is to replicate digital twin capabilities across the entire organization.

Training and Knowledge Transfer

Success was also driven by a strong training strategy. Young engineers were trained in structural modeling, mesh reduction, and result interpretation, while preserving the hands-on knowledge of experienced technicians. This combination strengthened the company’s innovation culture.

A Collaborative Ecosystem

The collaboration between Crucianelli, Siemens, and local partners was key. The integration of Teamcenter with SAP, automation of product configurations, and ongoing technical support enabled Crucianelli to accelerate innovation and improve competitiveness.

Conclusion

Crucianelli shows how a family-owned company can lead digital transformation in the agricultural sector. With Siemens Xcelerator, it has improved internal efficiency and developed more robust, precise, and field-ready products.