Industry: Automotive

The Challenge: Optimizing Next-Generation Hybrid Vehicle Performance

In an increasingly competitive and sustainability-focused automotive market, hofer powertrain faced the challenge of developing Dedicated Hybrid Transmission (DHT) systems that would maximize both fuel efficiency and vehicle performance. The complexity lies in the fact that having the best hardware is not sufficient: an intelligent energy management strategy is required to optimize the distribution between internal combustion energy and electric energy.

The Solution: Advanced Siemens Technology for Comprehensive Optimization

hofer powertrain chose the powerful tools from Siemens Digital Industries Software to address this complex challenge, implementing a comprehensive solution based on:

Simcenter Amesim: The Leading Simulation Platform

Siemens’ flagship tool for multi-physics system modeling enabled hofer powertrain to:

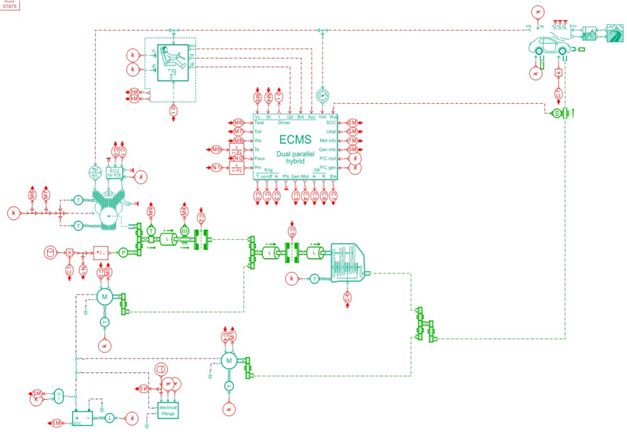

- Create precise models of the dual-parallel hybrid powertrain

- Implement the Hybrid Optimization Tool (HOT) with advanced algorithms

- Automatically generate forward models for dynamic validation

Simcenter HEEDS: World-Class Automated Optimization

Siemens’ multidisciplinary optimization solution provided:

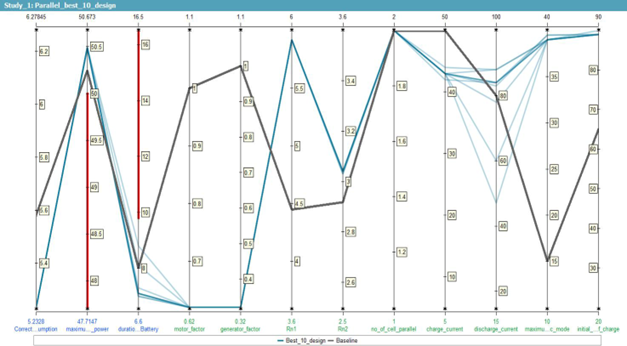

- Automated exploration of 250 design configurations

- Optimization algorithms that identified the optimal configuration

- Parallel analysis of multiple design variables simultaneously

Optimized System Architecture

- Dual-parallel hybrid vehicle equipped with a 1.2-liter internal combustion engine

- Dedicated Hybrid Transmission (DHT) optimized specifically for hybrid applications

- Advanced energy management system combining Pontryagin’s Minimum Principle for offline optimization and Equivalent Consumption Minimization Strategy for real-time optimization

Integrated Workflow with Siemens Technology

The synergy between Siemens tools created an unprecedented optimization process:

- Simcenter HEEDS automatically manages and varies design parameters

- Simcenter Amesim HOT calculates optimal control for each configuration

- The integrated Siemens ecosystem ensures seamless data transfer

- Automatic generation of the final optimized Simcenter Amesim model

“The native integration between Simcenter HEEDS and Simcenter Amesim was key to the project’s success, eliminating data transfer errors and significantly accelerating the optimization process.”

The Results: Siemens Technology Power in Action

Thanks to the computational power and advanced algorithms of Simcenter HEEDS, which automatically explored 250 different designs, and the precision of Simcenter Amesim for detailed modeling, the results were extraordinary:

Efficiency and Performance Improvements

| Metric | Baseline Design | Optimized Design | Improvement |

|---|---|---|---|

| Fuel consumption | 5.58 L/100km | 5.23 L/100km | -6.3% |

| 0-100 km/h acceleration | 8 seconds | 7 seconds | -12.5% |

| Maximum speed in electric mode | 54 km/h | 140.4 km/h | +160% |

Component Optimization

- 38% reduction in motor power scaling factor

- 68% reduction in generator power scaling factor

- 33% improvement in first gear transmission ratio

The Validation: Proven Precision of Simcenter Amesim

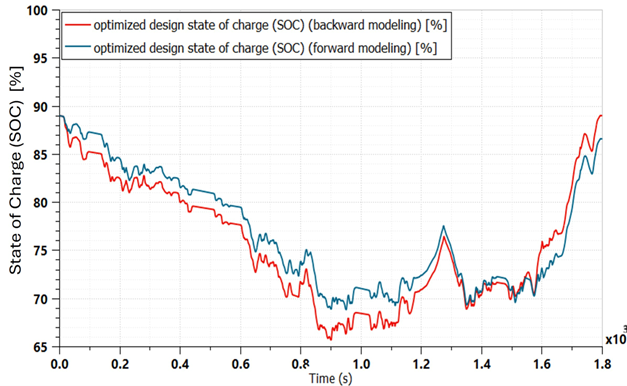

The project’s success was confirmed through the robust validation capabilities of Simcenter Amesim:

Integrated Dual Modeling

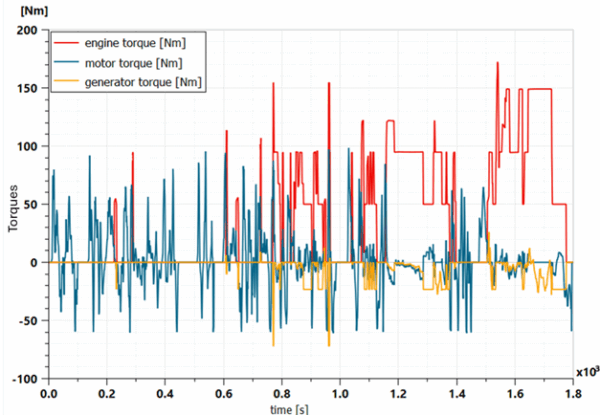

- Backward model (Simcenter Amesim HOT): High-speed quasi-static optimization

- Forward model (Simcenter Amesim): Dynamic simulation with real transient effects

- Automatic transition between models without data loss

Validated Results

The consistency between both modeling approaches demonstrated the exceptional precision of Siemens tools:

- Optimized consumption: 5.23 L/100km (backward model) vs 5.24 L/100km (forward model)

- Less than 0.2% difference between simulations, confirming software reliability

The Impact: Siemens Ecosystem Transforming the Industry

This success case demonstrates how Siemens Digital Industries Software integrated solutions can:

Accelerate innovation: Drastic reduction in development time through automation

Guarantee precision: Cross-validation between multiple modeling approaches

Optimize resources: 250 designs explored automatically vs. years of physical testing

Drive sustainability: 6.3% less consumption = significant emission reduction

Competitive Advantages of the Siemens Ecosystem

- Native integration between tools eliminates transfer errors

- Scalability for projects of any complexity

- World-class algorithms in multidisciplinary optimization

- Specialized technical support from our strategic partner Siemens

Future Perspectives with Siemens

hofer powertrain continues innovating with the Siemens solutions ecosystem, exploring:

- Simcenter Amesim for battery aging modeling

- Simcenter HEEDS for next-generation modular architectures

- Integration with other Siemens solutions for renewable energy

Why Choose Siemens Solutions?

Proven Precision: Less than 0.2% differences between models

Development Speed: 250 designs optimized automatically

Total Integration: Complete ecosystem without data loss

Measurable Results: 6.3% less consumption, 12.5% better acceleration

This success case demonstrates the transformative power of Siemens Digital Industries Software in hybrid vehicle optimization, validating our strategic alliance to deliver the best market solutions.

Ready to revolutionize your hybrid vehicle development? As an authorized Siemens partner, we offer complete access to these world-class tools, along with specialized technical support and certified training.