Industria: Automovilismo

Reaume Brothers Racing is a professional American stock car racing team competing full-time in the NASCAR Craftsman Truck Series. Led by Josh Reaume, the team fields the No. 22 Ford F-150 with various drivers, the No. 27 part-time for Keith McGee, and the No. 33 full-time for Lawless Alan.

As an engineering-driven team, Reaume Brothers Racing is constantly exploring innovative solutions to stay competitive in a sport where strict regulations and limited testing opportunities are the norm. On top of that, they must ensure their constantly modified vehicles remain compliant with NASCAR rules at every race.

The Challenge: Traditional 3D Measurements Hindered Innovation

One of the team’s biggest challenges was acquiring accurate 3D measurements of their truck bodies. Initially, they relied on low-precision methods such as tape measures—leading to errors and inconsistencies that jeopardized compliance with NASCAR standards.

This lack of precision not only introduced a high risk of human error but also restricted engineers’ ability to confidently evaluate the condition of the vehicles both before and after races. At one point, they even outsourced their 3D measurement needs to a competitor—far from ideal in such a high-stakes environment.

The need to take control of this process in-house—ensuring accuracy, reliability, and confidentiality—was the turning point that led the team to seek a better solution.

The Solution: Creaform’s MetraSCAN 3D Solves the Accuracy Problem

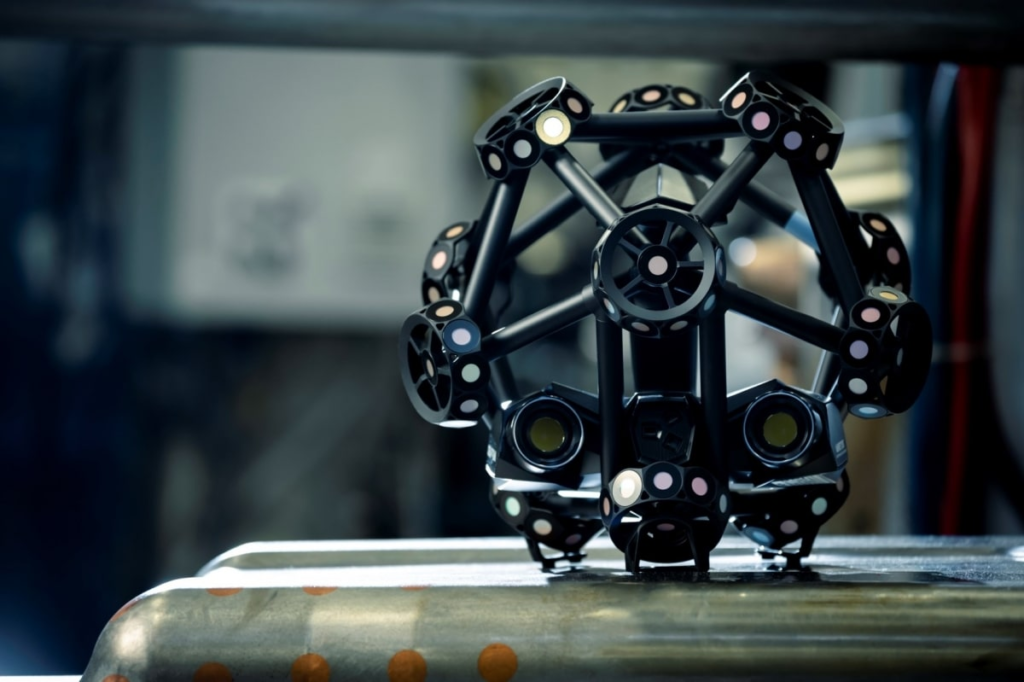

Reaume Brothers Racing turned to Creaform’s MetraSCAN 3D for its speed, precision, user-friendliness, and repeatability. Paired with VXinspect for dimensional inspection, the system quickly became a key tool in their quality control process.

The implementation was fast and efficient. After just a few days of training, team members were scanning confidently. They initially used MetraSCAN 3D to establish setup protocols, enabling them to generate accurate 3D measurements and deliver detailed printouts to crew chiefs. This dramatically sped up vehicle setup times between races.

One of the team’s most impactful projects was replicating headrest mounts for their carbon fiber racing seats. Each mount was scanned twice, the scans were merged to fill in gaps, and precise part drawings were generated. This allowed for the seamless production of additional mounts, ensuring their seats were always race-ready.

The Results: Improved Quality Control and Performance

Creaform’s technology has completely transformed Reaume Brothers Racing’s quality control approach. The ultra-precise, high-resolution scans from MetraSCAN 3D allow the team to monitor and maintain their steel-fabricated truck bodies within NASCAR’s strictest tolerances.

Amir Alexander, Team Manager at Reaume Brothers Racing, shared:

“MetraSCAN 3D has significantly improved our ability to maintain and optimize our race vehicles. The precision and ease of use have been game-changers for us.”

He also highlighted the cost and time savings:

“Before we had our Creaform scanner, we had to transport the vehicle to a third-party provider, costing us around $2,000 and a full day—including prep and unloading. Plus, it exposed sensitive data about our trucks to competitors. Now, one employee can complete a scan in the same amount of time it used to take just to load the truck.”

Since implementing the scanner, the team has completed 17 truck scans and 8 part scans—each one delivering critical insights that give them an edge over their rivals.

Conclusion: Gaining a Competitive Edge with 3D Metrology

Creaform’s MetraSCAN 3D has become an essential asset for Reaume Brothers Racing. With its accurate, repeatable measurements, the team has reduced reliance on imprecise tools and human guesswork—ensuring their trucks stay compliant and perform at peak levels.

The success of projects like the headrest mount replication clearly shows how fast, reliable 3D scanning supports high-performance engineering.

As Amir summed it up:

“Implementing Creaform’s technology has given us the confidence to push our engineering further and maintain our edge in this highly competitive sport.”