Industry: Automotive

Designing Smart Vehicles

The China FAW Co., Ltd. R&D Center is the largest research, development, testing, and inspection facility for the automotive industry in China and serves as a key technology center for the original equipment manufacturer (OEM), FAW Group Corporation, and the Chinese government. The company focuses on developing commercial vehicles and automotive components, with engineering expertise covering the entire vehicle development cycle.

As part of the “Made in China 2025” initiative, the FAW R&D Center has taken on the challenge of establishing research and development (R&D) functions for the department of intelligent networking vehicles to develop smart vehicles. Electrifying and automating driving functions increase system complexity, requiring early validation of controllers.

The development of intelligent networking vehicles is a major focus for many automakers in China and globally. For FAW’s Intelligent Networking Vehicles R&D Department, the creation of advanced vehicles presents a significant challenge, as it demands intensive use of advanced development technologies.

Implementing Model-Based Systems Engineering

The FAW Intelligent Networking Vehicles R&D Department sought a supplier with experience in full-vehicle modeling, including real-time and online plant modeling and controls development. Additionally, they aimed to improve their development process and sought a partner open to sharing its knowledge and methodologies.

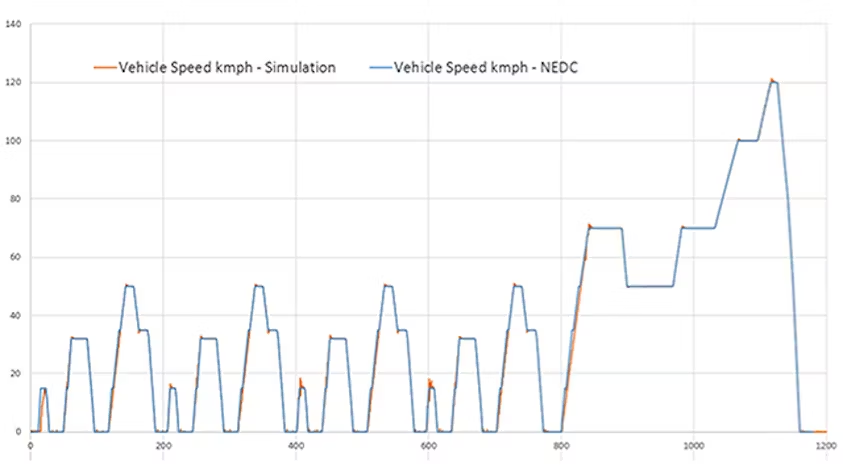

Zheng Lei, administrative office director of FAW’s Intelligent Networking Vehicles R&D Department, explains, “We needed to perform offline simulations using the complete vehicle model to analyze performance and to meet the demand for real-time simulation on the hardware-in-the-loop testing platform. We also needed a technology partner to enhance our internal knowledge through a technology transfer service.”

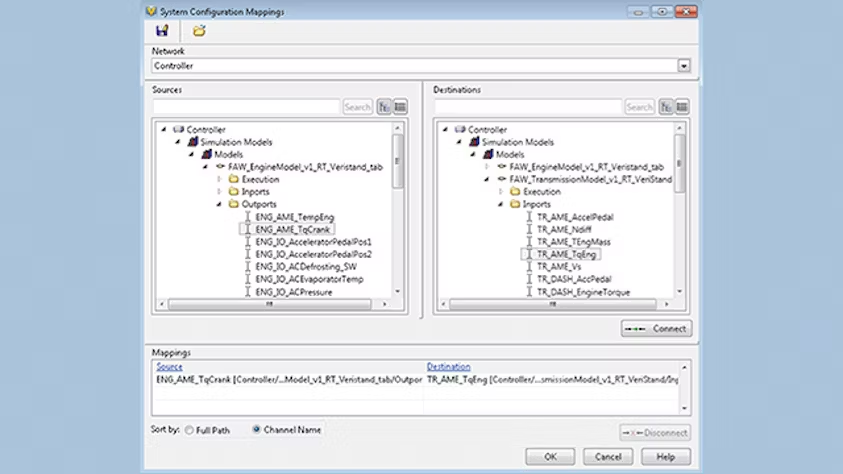

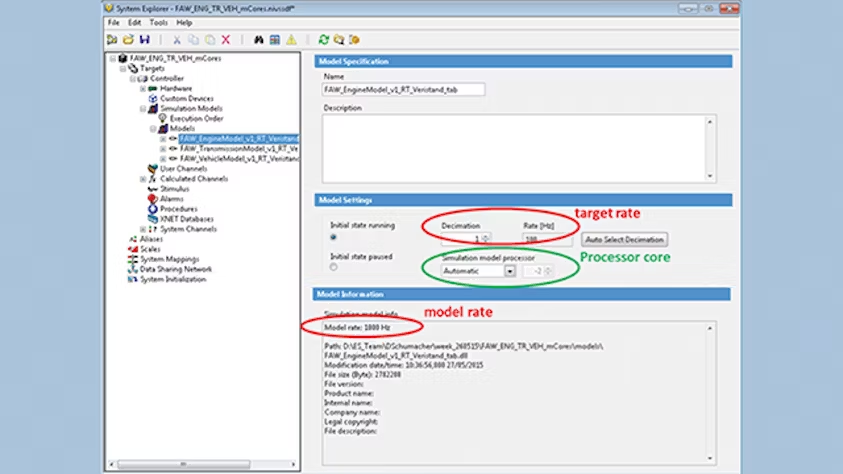

With the support of Simcenter Engineering services and Simcenter Amesim™ software from Siemens Digital Industries Software, FAW implemented model-based systems engineering (MBSE). Simcenter Amesim enables users to create models of varying complexity to meet requirements at different stages of vehicle development. Additionally, it supports hybrid hardware-in-the-loop (HiL) testing for controls verification and model validation.

Simcenter Amesim provides an accessible, open development environment that facilitates joint modeling and effective collaboration between different departments and with suppliers. “It enables a consistent modeling approach even with different levels of model complexity throughout the development process,” Zheng adds.

Working Together Seamlessly

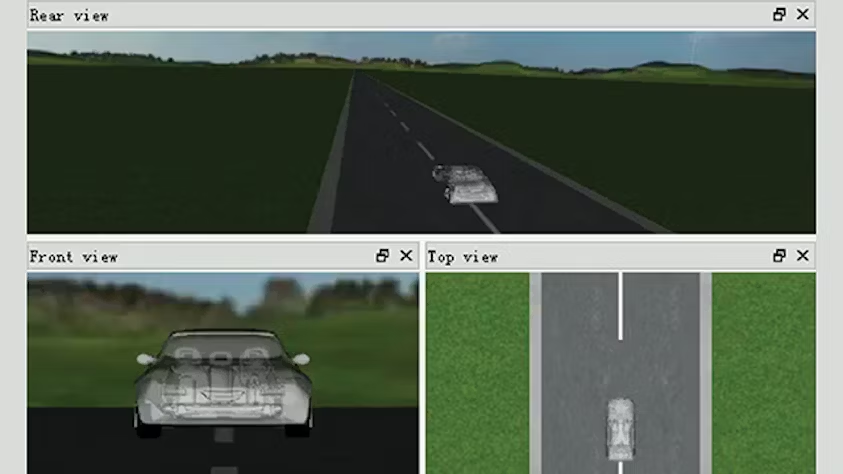

FAW and Simcenter Engineering teams collaborated seamlessly to build a solid framework for advanced vehicle dynamics analysis, for both offline and real-time simulation. The Simcenter Engineering team helped FAW virtually validate the vehicle’s electronic control units (ECUs) like electric power steering (EPS), electronic stability program (ESP), and anti-lock braking system (ABS).

The engineering experts assisted FAW in defining processes, integrating models, and constructing scenarios for HiL testing. They also developed a real-time predictive control (MPC) driver model for vehicle trajectory control, which offers a systematic, streamlined process for designing complex multivariable control systems.

Leveraging Simcenter for Competitiveness

Thanks to Simcenter Amesim and Simcenter Engineering expertise, FAW completed a real-time modeling project for a vehicle independently developed by the company. Through HiL simulation and testing, they conducted virtual simulation-based controller testing and troubleshooting, significantly reducing the development cycle for the vehicle’s electronic control system.

All units within FAW’s Intelligent Networking Vehicles R&D Department now use Simcenter Amesim for vehicle systems design, greatly facilitating system integration, controls validation, HiL simulation, and model verification. Key functionalities like high-frequency engine models, real-time model reduction tools, and the Functional Mockup (FMU) interface for model exchange have optimized the design and testing process.

Enhancing Competitiveness

The China FAW Group Corporation R&D Center has long been a leader in HiL system simulation and testing in China, striving to reach international standards. “Thanks to Simcenter solutions, we now have the ability to model independently, which makes us even more competitive,” Zheng remarks. “We’ll continue working with world-class suppliers like Siemens Digital Industries Software to drive the development of products and technologies.”

Dr. Zheng Lei, Administrative Office Director, R&D Department, Intelligent Networking Vehicles, China FAW Group Corporation R&D Center