Industry: Automotive

Transitioning to Zero-Emission Buses: Challenges and Solutions

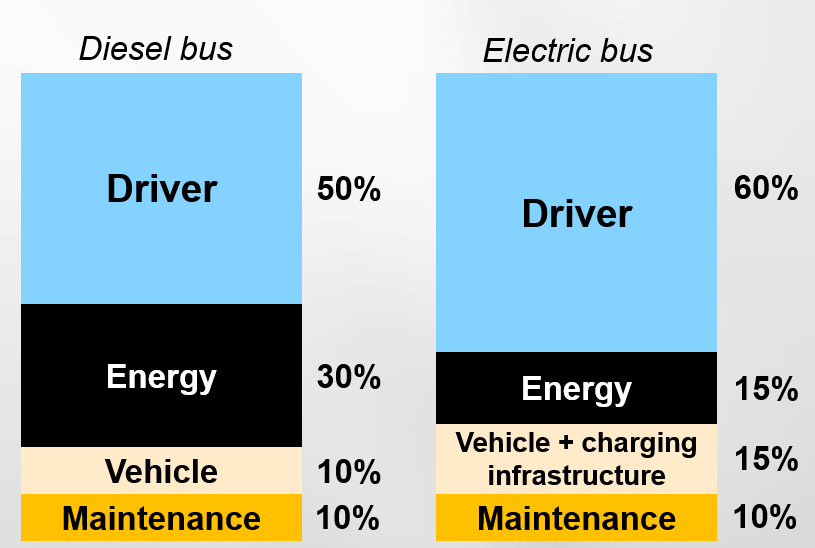

When considering the switch to zero-emission buses, the transition can initially seem expensive. However, bus manufacturer VDL discovered that switching to an electric bus is actually cheaper per kilometer than a diesel one! We spoke with Anouk Hol, aerodynamics and energy specialist at VDL, to discuss this new trend and the challenges it brings.

Similarities Between the Automotive and Bus Industries

There are many similarities between the automotive and bus industries. “We can learn from car manufacturers, for example by using the same battery cells and packs,” says Hol. However, in buses, the batteries need to be larger due to greater capacity requirements. Buses easily drive between 300 and 500 kilometers a day, and their behavior—low speeds, constant stopping—is vastly different from that of a car.

Challenges in Designing Zero-Emission Buses

With this new direction, VDL had to strengthen its software and control expertise as they now supply not just buses but a full system, including charging infrastructure and assistance with scheduling. “When switching to zero-emission buses, we also switched from supplying a bus to supplying a system,” Hol explains.

Cities require different charging infrastructures, ranging from 24/7 services needing fast charging at bus stops to lighter services relying on larger batteries and slower charging once or twice a day.

The Use of Modeling in the Development Process

This is where the need for modeling and simulation tools emerged. It was essential to determine the best configuration early in the process, even before moving to the engineering and prototyping phases, allowing them to offer tailored solutions to customers.

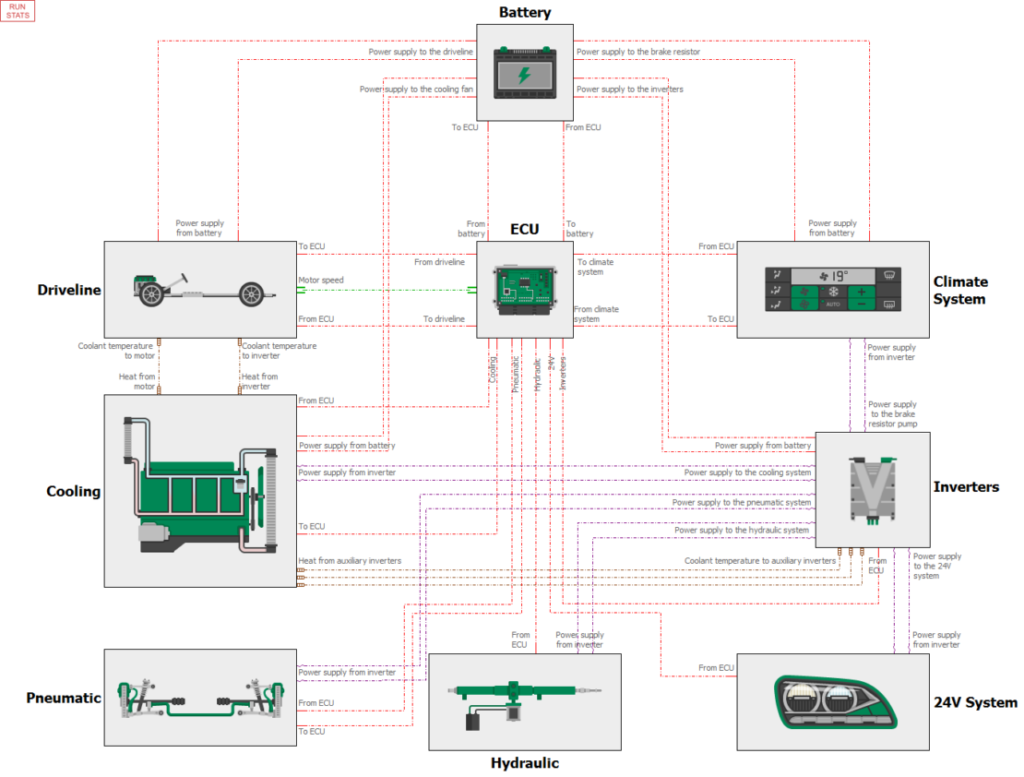

Simcenter™ Amesim™ software was used for various purposes, such as mapping energy flow within the vehicle and optimizing battery size and charging time to improve overall efficiency.

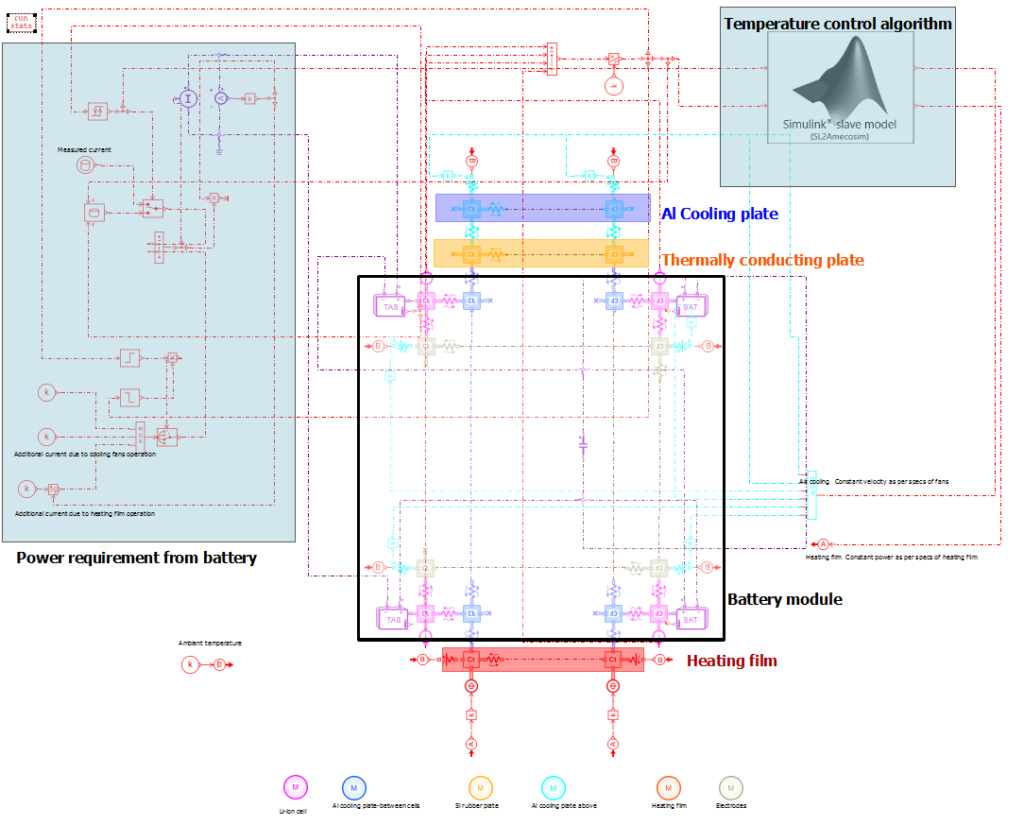

Detailed Battery Cell and Pack Modeling

VDL created detailed models of battery cells and packs and ran simulations to predict their behavior. By combining all bus components, including the vehicle control unit, VDL could accurately predict performance and optimize supplier selection.

Mapping Energy Flows

Simulation was also used to map energy flows within the vehicle. By combining Simcenter Amesim with Simcenter™ STAR-CCM+™ software, VDL imported 3D information to better analyze complex behaviors, such as battery cooling.

Battery Management Systems

Simcenter tools were also used to validate battery control strategies, combining electrical and thermal calculations to fine-tune control parameters and improve vehicle energy management.

The simulation models helped VDL analyze various customer usage profiles, providing clear insights into their component choices.