Industry: Automotive

Karma Automotive, a luxury electric vehicle manufacturer, has successfully resurrected an iconic electric hybrid sedan using Siemens solutions to optimize its development process. Based in Irvine, California, and owned by Wanxiang Group, Karma faced the challenge of developing a luxury hybrid sedan, improving NVH (noise, vibration, and harshness) performance, and reducing the number of design iterations.

To overcome these challenges, the company digitized its development processes and received expert assistance from Simcenter engineering services. They used a combination of simulation and testing in the vehicle’s development and adopted Polarion ALM to manage the software lifecycle.

Results:

- Surpassed NVH optimization, improving the overall development process.

- Enhanced NVH performance with a minimum number of design iterations.

- Integrated testing and simulation into a single platform.

- Facilitated team and division collaboration through streamlined data exchange.

Bob Kruse, Chief Technical Officer of Karma Automotive, emphasized that Siemens’ consulting services and software tools helped them optimize the process with minimal iterations, ensuring precision and efficiency from the early stages of development.

The rise of electric sports cars:

Electrification has revolutionized the automotive industry, with over 12 million hybrid or electric vehicles sold globally. While electric cars haven’t yet dominated the roads, they have reshaped perceptions, and luxury brands like Tesla, BMW, Jaguar, and Porsche have launched high-performance electric and hybrid models.

Karma Automotive, a California-based startup, emerged from the assets of Fisker Automotive in 2014. While maintaining Fisker’s attractive Italian design, Karma significantly upgraded the technology, creating a luxury hybrid sedan that combines the best of the original design with modern technological advances.

NVH optimization in a hybrid-electric sports car:

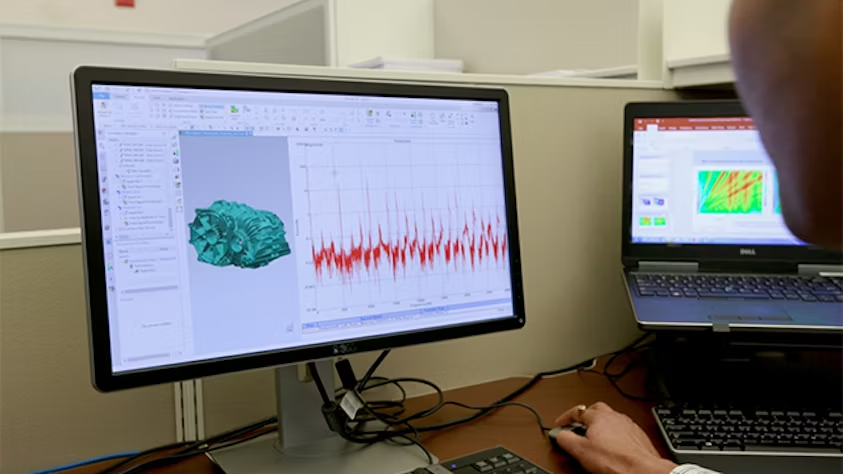

One of the major challenges in hybrid cars is managing engine noise, as the lack of combustion engine noise makes other sounds, like road and HVAC noise, more noticeable. Karma used Simcenter 3D and Simcenter Testlab to balance noise reduction without negatively impacting other attributes, such as weight or durability.

By using simulation and testing simultaneously, Karma efficiently optimized NVH performance, combining hybrid modeling and physical testing. Simcenter 3D helped simulate components under development, while Simcenter Testlab validated these models using physical test data.

Simcenter engineering and consulting services:

In addition to software tools, Simcenter’s engineering and consulting services were crucial to the project’s success. These services helped Karma optimize both the product and process development, minimizing last-minute corrections during the validation phase.

The added value of Polarion:

To manage multiple software capabilities and facilitate collaboration between teams and divisions, Karma adopted Polarion ALM. This tool allowed them to track objectives from the vehicle level down to the component level, ensuring full control over the application lifecycle and improving agility throughout the development process.

Conclusion:

With Siemens’ services, Karma Automotive not only met but exceeded its technical targets. The combination of simulation, testing, and an optimized process allowed them to successfully launch their luxury hybrid sedan to the market. With this process firmly in place, Karma is ready to take on new challenges and expand its electric vehicle lineup in the future.