Industry: Casting

In the large-scale die casting industry, where every detail matters and errors can lead to costly delays, EXCO Engineering has taken a decisive step to ensure unparalleled quality: adopting Creaform’s 3D scanners and software as a central part of their inspection processes.

A Legacy of Innovation and Precision

Located just 30 minutes from Toronto, EXCO Engineering is a global leader in die casting solutions for powertrain, body, and structural components. Operating from a 130,000-square-foot facility equipped with state-of-the-art machinery, in-house casting capabilities, and a 4,000-ton die casting machine, the company has supplied tooling for major automotive programs, from engine blocks to body panels.

With decades of experience, EXCO has consistently aimed to exceed customer expectations through high-precision engineering solutions.

The Challenge of Inspecting Increasingly Complex Molds

As die-cast parts grew in size and complexity, traditional inspection methods—like coordinate measuring machines (CMMs)—began to show their limitations. The quality team faced difficulties inspecting deep cavities, areas near pins, and internal ribs, even with one of North America’s largest CMMs.

This posed a significant risk: overlooking machining errors or missing engineering changes could lead to mold failures and halt customer production.

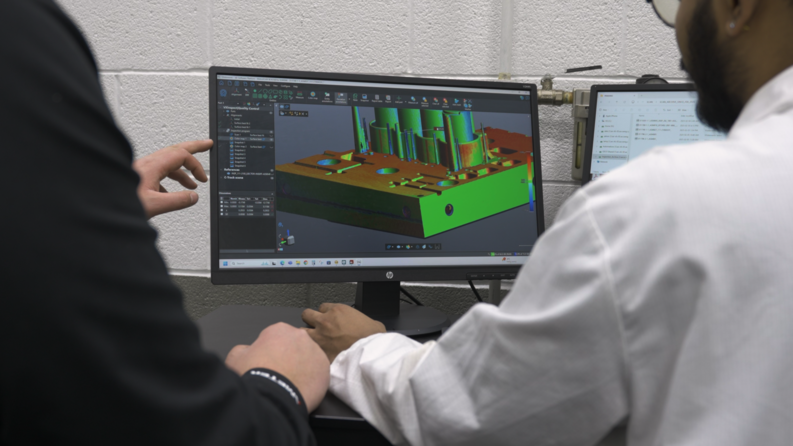

Transitioning to 3D Scanning

Recognizing these challenges, EXCO Engineering integrated 3D scanning into their operations, choosing Creaform’s technology. While the transition initially met some resistance, the accuracy, portability, and versatility of the MetraSCAN 3D scanner quickly won over the team.

“With the CMM, it felt like we were viewing the molding area on an old black-and-white TV. Now, with Creaform’s scanning software and the MetraSCAN 3D in our daily activities, it’s like seeing the results in 4K—we can clearly see what’s happening,” said Jonathan Koot, Quality Systems Manager at EXCO Engineering.

Immediate Improvements in Quality and Efficiency

Implementing the MetraSCAN 3D allowed for direct scanning on the production floor, even inside CNC machines or on suspended parts. By capturing complete surface profiles, the generated color maps provide detailed analysis, facilitating error detection and swift decision-making.

Additionally, Creaform’s intuitive inspection software enables the generation of comprehensive visual reports in minutes, streamlining workflows and reducing inspection times by half for certain parts.

A Key Partner in Continuous Improvement

Beyond the technology, EXCO highlights Creaform’s customer support as a critical factor in their success. From immediate assistance to personalized on-site training, the user experience has been outstanding.

“They set the support standard so high that I forget what normal support is like,” Koot remarked.

Ensuring Quality from the Workshop

Through this collaboration, EXCO Engineering has eliminated critical errors before they reach the customer, ensuring parts meet the highest standards of quality and performance. Today, 3D scanning is not just an inspection tool but a cornerstone of their continuous improvement strategy.