With over 90,000 employees worldwide, Siemens Energy is a global company operating in various sectors of the energy industry, including grid technologies, decarbonization of industries, wind energy, and conventional power generation.

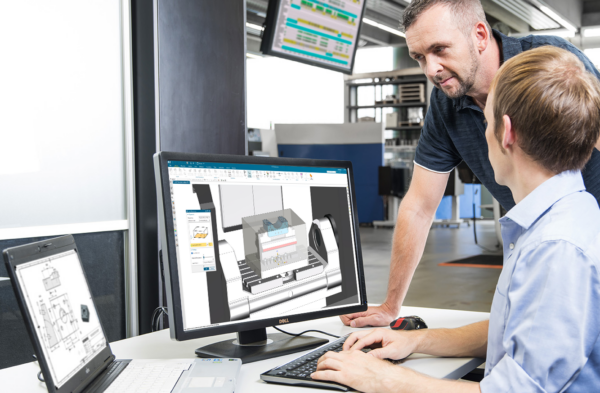

Located in Mülheim, Germany, the metrology group is part of the on-site machining department. Its primary focus is developing and retrofitting specialized machinery for on-site operations in power plants. The machining department also provides on-site maintenance and repair services for power plants. This service benefits the customers by ensuring short repair time, high-quality service, and the use of high-performance equipment that local workshops may not have.

Over the years, new applications have emerged, and new power plants have been built. Siemens Energy needed to increase its capacity to complete its tasks more efficiently. So, the metrology department started looking for new technologies available on the market to accelerate their work and manage their tasks within a few hours or days (instead of a week or two). This led them to the Creaform HandySCAN 3D|MAX Series.

Teams at Work at the Factory and Power Plants

Siemens Energy employs 3D scanning technology at its factory in Germany to validate the quality of parts it produces or those it receives from suppliers. The company also deploys its expert teams on-site to replace old, worn components, such as turbine rotors. By conducting thorough facility scans and precise measurements, they can reverse engineer replacement parts to ensure seamless integration with existing systems. Moreover, Siemens Energy goes beyond mere replacements by designing new parts that enhance the energy efficiency of power plants, contributing to both improved performance and environmental sustainability.

Making Accurate Measurements in a Short Time

During on-site measurements, the teams must efficiently meet the customer’s expectations within the given time window. They must capture all necessary information within the allotted time, as components may become inaccessible after the measurement period, which can occur between different machining slots, such as before or after assembly and reassembly.

Variety of Parts, from Tiny to Gigantic

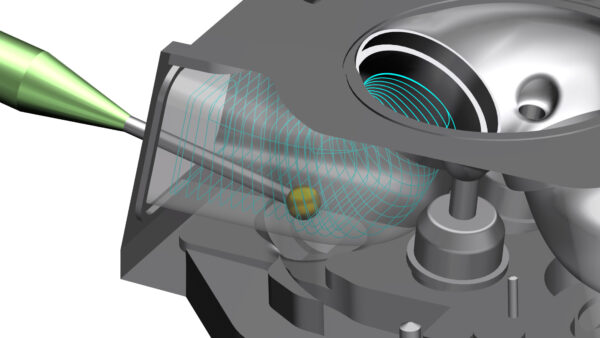

Siemens Energy’s work often occurs in a humid and hot environment where strong vibrations are ubiquitous. In such a context, the teams must perform a variety of optical measurements on parts of a few centimeters up to 14 meters in size, from simple geometries, such as boreholes, to large and complex shapes like turbine blades, rotors, and castings.

As a result, Siemens Energy requires a high level of accuracy and resolution for measuring parts of all sizes, typically crafted from steel and featuring polished surfaces.

Limitations of the Previous Technology

Before relying on portable 3D scanners with high-resolution capabilities over large parts, Siemens Energy depended on manual field surveys using photos and conventional tools to carry out its tasks. However, it was common to encounter incomplete or unreliable information, resulting in delays or reduced efficiency during repair and maintenance.

Time being their most critical constraint, teams at Siemens Energy had to address these delays in repair and maintenance. Replacement parts had to perform optimally and fit perfectly the first time without iterations.

Helpful Collaboration Leading to the HandySCAN 3D|MAX Series

Siemens Energy is an early adopter renowned for its commitment to exploring and embracing new technologies. As a longstanding partner of Creaform, the company agreed to collaborate on the development of the HandySCAN 3D|MAX Series, yielding impressive results that underscore their shared dedication to innovative technologies.

Quick Measurement of Large Parts

With the HandySCAN 3D|MAX Series, the on-site maintenance and repair teams can scan large parts, as big as turbine rotors measuring up to 14 meters, in fine detail. Compared to the old system, whose setup and acquisition were long and complicated, teams can now scan more parts while saving time. The speed of the acquisition process makes all the difference because it enables Siemens Energy to limit downtimes during part replacement. Customers save money by saving time because every hour a power plant does not operate is an hour it cannot earn money.

Flex Volume for High Resolution AND High Speed

The MAX Series presents the Flex Volume feature, which gives Siemens Energy the flexibility to scan large parts at high speed from a longer distance (Far Mode) or measure smaller areas with high resolution at a short distance (Near Mode). The teams can also use the standard mode to benefit from both speed and resolution when scanning valves and connectors. This combination of speed and resolution allows them to quickly capture all the small details and ensure everything fits in its proper place on the first try during installation.

Portable Everywhere

Siemens Energy provides repair and maintenance services directly to power plant locations. On-site, the teams handle large and difficult-to-move parts in environments with high temperatures and steady vibrations. With the HandySCAN 3D|MAX Series, Siemens Energy can now perform all measurements and tasks with a single reliable device that is easily transportable and adapted to the instabilities of industrial environments.

Better Versatility for More Simplicity

Siemens Energy is particularly fond of the Smart Surface Algorithm feature, which automatically adjusts the camera shutter using advanced image processing combined with artificial intelligence. This feature enhances the performance of the MAX series and provides better readings of difficult contrasting finishes. As a result, anyone can enjoy a simpler and more straightforward scanning process, regardless of their level of expertise or experience.

HandySCAN 3D| MAX Series, A Game Changer for Siemens Energy

Over the past 13 years, the partnership between Siemens Energy and Creaform has consistently proven to be a win-win relationship. The introduction of the new measuring tool, the HandySCAN 3D|MAX Series, marks a significant milestone in this collaboration, serving as a game changer for Siemens Energy. Due to its unwavering commitment to innovation, Siemens Energy is dedicated to delivering better results to its customers in shorter time frames. The HandySCAN 3D|MAX Series embodies this commitment, allowing the company to meet and surpass its customers’ expectations.