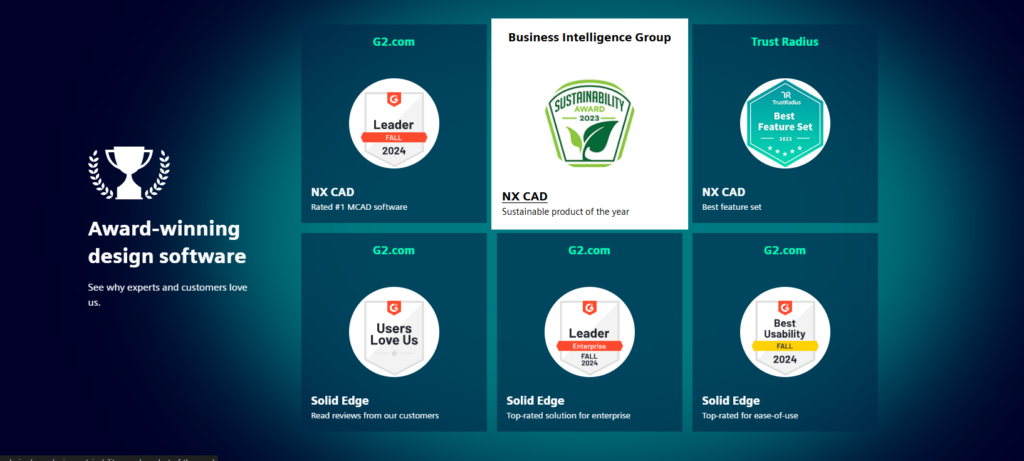

An article was published on the official Siemens Digital Industries Software website that fills us with pride: Goaltech was highlighted as a success story for its role in the digital transformation of Mexican industry. This mention reinforces our commitment to innovation and the adoption of technologies that drive competitiveness in key sectors.

What does Siemens highlight in its article?

The case study describes how Goaltech, as an authorized Siemens partner, has supported Mexican companies in implementing solutions that optimize processes and reduce costs. The publication highlights our expertise in tools such as Tecnomatix, NX, Solid Edge, and Valor, which are essential for improving efficiency in electronics manufacturing and automation.

Impact on the industry

The official article emphasizes that our collaboration with Siemens is not only focused on software sales, but also on technology integration and specialized training, helping our customers face challenges such as reducing time-to-market and migrating to more agile and digital processes.

Read the full article on the official Siemens website:

https://resources.sw.siemens.com/en-US/case-study-goaltech/

Thank you for joining us on this journey

At Goaltech, we are proud of this recognition from Siemens, which reflects our commitment to innovation and technological excellence. We invite you to learn more about our solutions and how we can help your company take the next step toward digitalization.